Mining machinery coal sample mixing machine

A kind of mixing and mechanical technology, applied in the field of mining machinery, can solve the problems of cumbersome process, dust in the mixing process, large labor-intensive error, etc., to achieve the effect of speeding up the mixing efficiency, speeding up the mixing and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

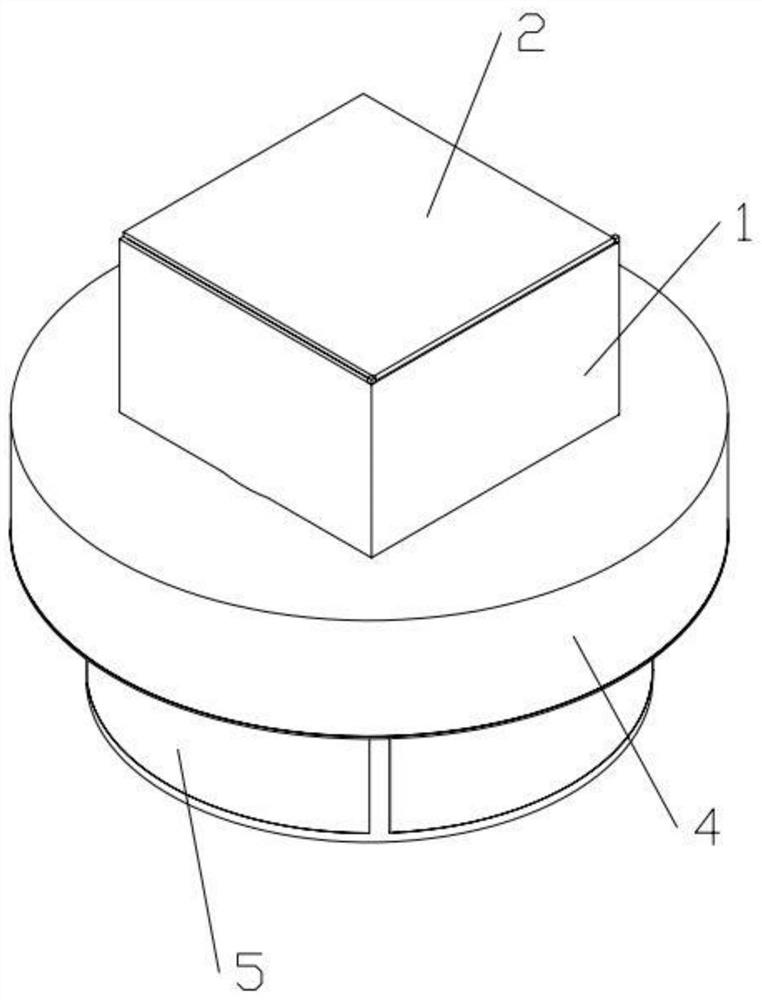

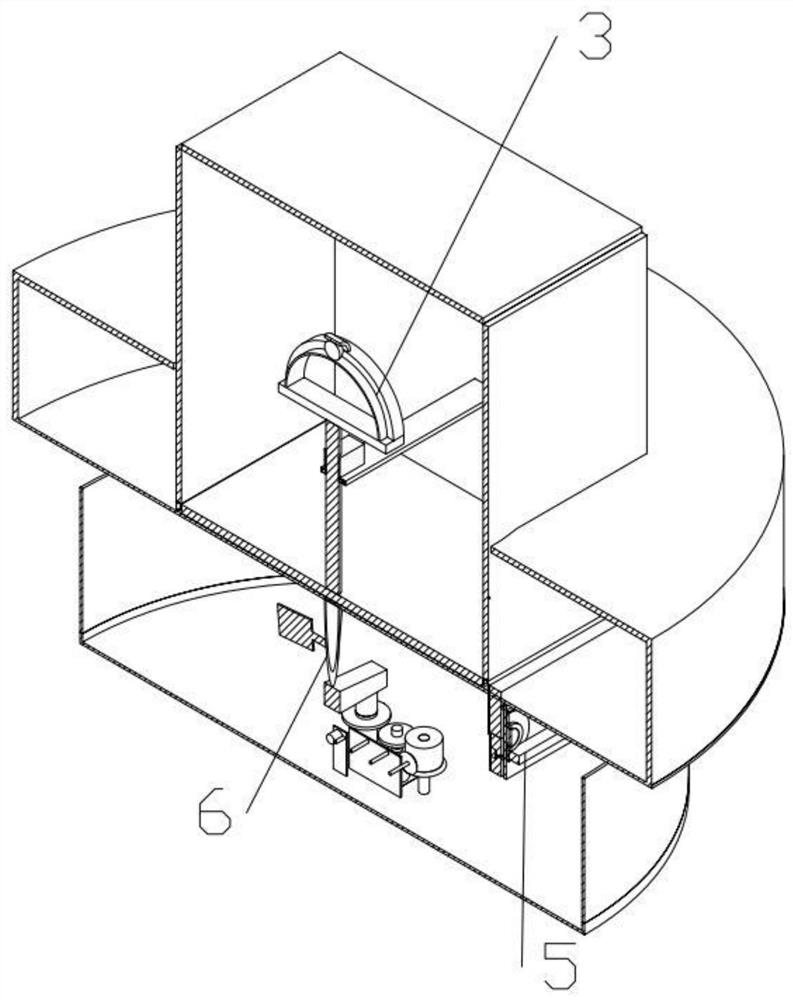

[0036] Combine below Figure 1-19 In order to solve the above technical problems, the present invention relates to the technical field of mining machinery, more specifically, a coal mixing machine for mining machinery, including a mixing box 1, a material inlet door 2, a mixing mechanism 3, a protective shell 4, and a discharge device 5 and auxiliary device 6; the sample mixing box 1 is hinged with the feeding door 2, a sample mixing mechanism 3 is arranged in the sample mixing box 1, a protective shell 4 is arranged around the sample mixing box 1, and the sample mixing box 1 is provided with a protective shell 4. The bottom of the box 1 is connected to the discharge device 5, and the protective shell 4 is connected to the auxiliary device 6;

[0037] Firstly, the feed door 2 is opened, and then the coal is prevented from entering the mixing box 1 through the feed door 2, and the movement of the protective shell 4 is controlled by the auxiliary device 6, and the coal is mixed ...

specific Embodiment approach 2

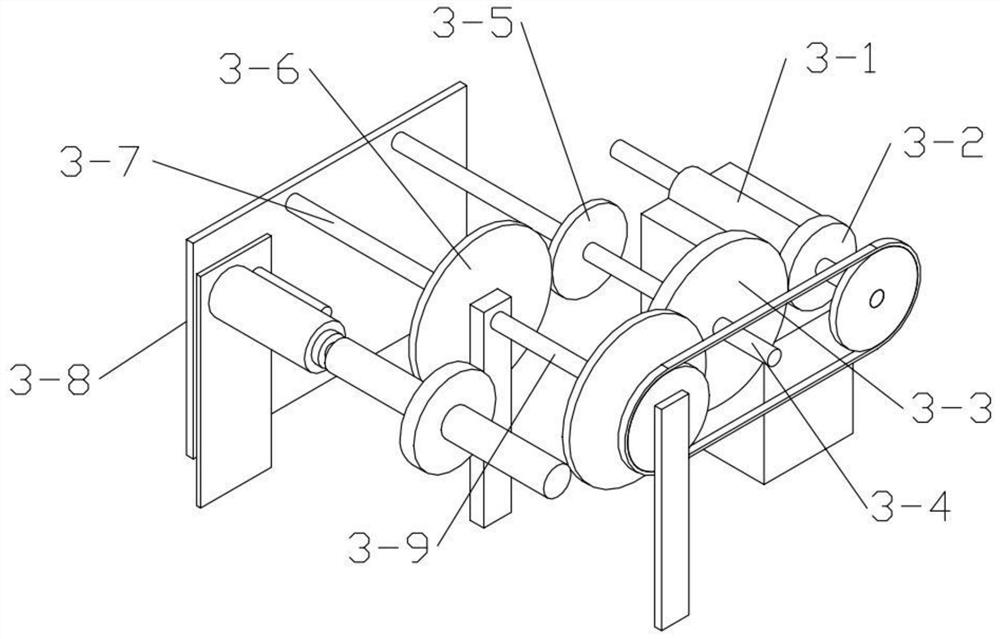

[0039] Combine below Figure 1-19 Describe this embodiment, this embodiment will further explain Embodiment 1, the sample mixing mechanism 3 includes a drive motor 3-1, a first sample mixing deceleration wheel 3-2, a second sample mixing deceleration wheel 3-3, a first Mixing shaft 3-4, third mixing reduction wheel 3-5, fourth mixing reduction wheel 3-6, second mixing shaft 3-7, first connecting plate 3-8, third mixing shaft 3 -9, the first mixing belt pulley 3-10, the first mixing driving wheel 3-11, the first mixing connecting belt 3-12, the second mixing belt pulley 3-13, the second mixing driving wheel 3 -14, the fourth mixing shaft 3-15, the first mixing electric push rod 3-16, the third mixing driving wheel 3-17, the fifth mixing shaft 3-18, the third mixing pulley 3- 19. The second mixing belt 3-20, the fourth mixing pulley 3-21, the mixing worm 3-22, the mixing turbine 3-23, the mixing protection box 3-24, the sixth mixing shaft 3 -25, the first mixed sample connecti...

specific Embodiment approach 3

[0046] Combine below Figure 1-19Describe this embodiment, this embodiment will further explain the first embodiment, the discharge device 5 includes the first discharge electric push rod 5-1, the first discharge rack 5-2, the first discharge gear 5- 3. The first discharge shaft 5-4, the first discharge pulley 5-5, the first discharge connection belt 5-6, the second discharge pulley 5-7, the second discharge shaft 5-8, The third discharge pulley 5-9, the second discharge connection belt 5-10, the fourth discharge pulley 5-11, the third discharge shaft 5-12, the first discharge rod 5-13, the first Discharge restriction frame 5-14, discharge transmission block) 5-15, second discharge restriction block 5-16, second discharge rod 5-17, second discharge door 5-18, discharge connection block 5 -19, discharge drive wheel 5-20, third discharge restriction frame 5-21, fourth discharge restriction frame 5-22, sample storage box 5-23 and sampling door 5-24; A first discharge electric p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com