Activated carbon high-temperature detection and graded alarm method

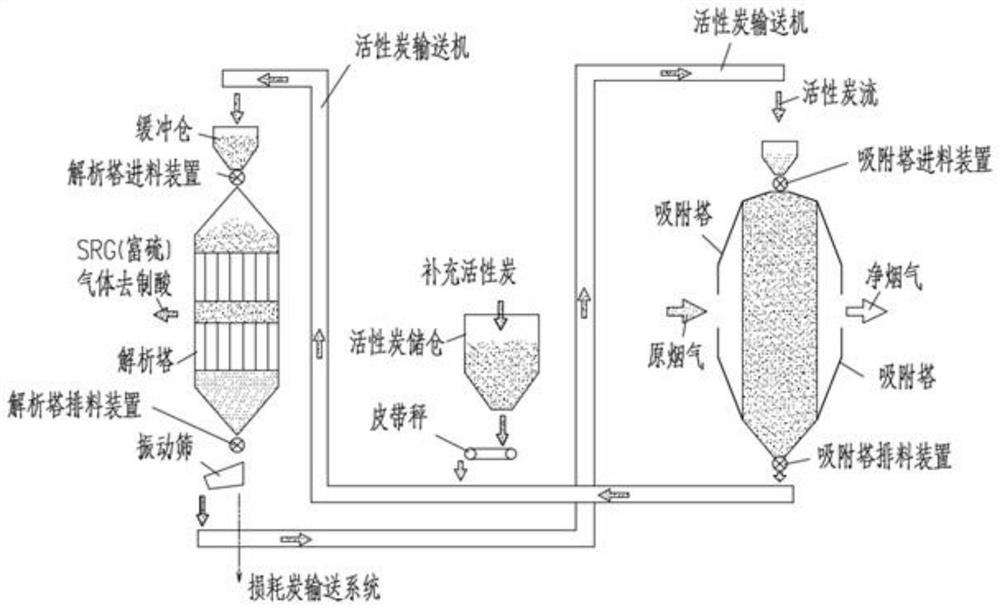

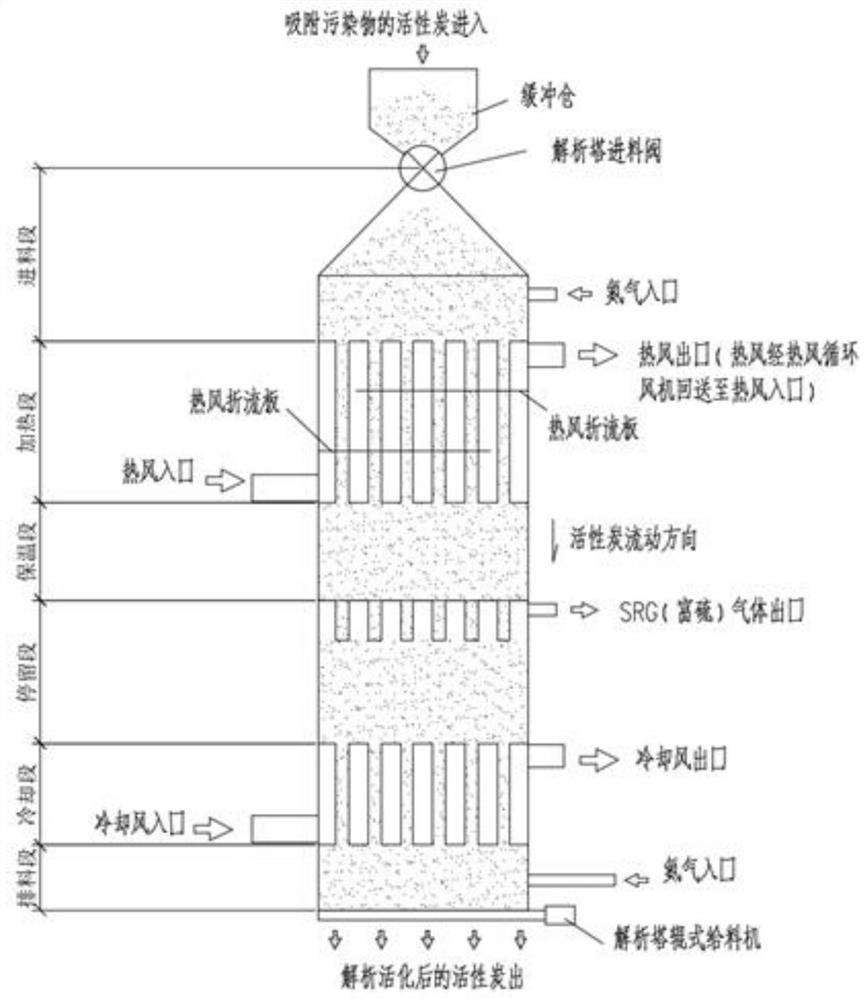

A graded alarm and activated carbon technology, which is applied to the detection of high-temperature activated carbon particles in activated carbon flue gas purification devices, the field of activated carbon high-temperature detection and graded alarms, can solve the problems of unsolved high-temperature activated carbon detection and positioning, and achieve the elimination of observation obstacles and improve Accuracy, the effect of optimizing the imaging environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

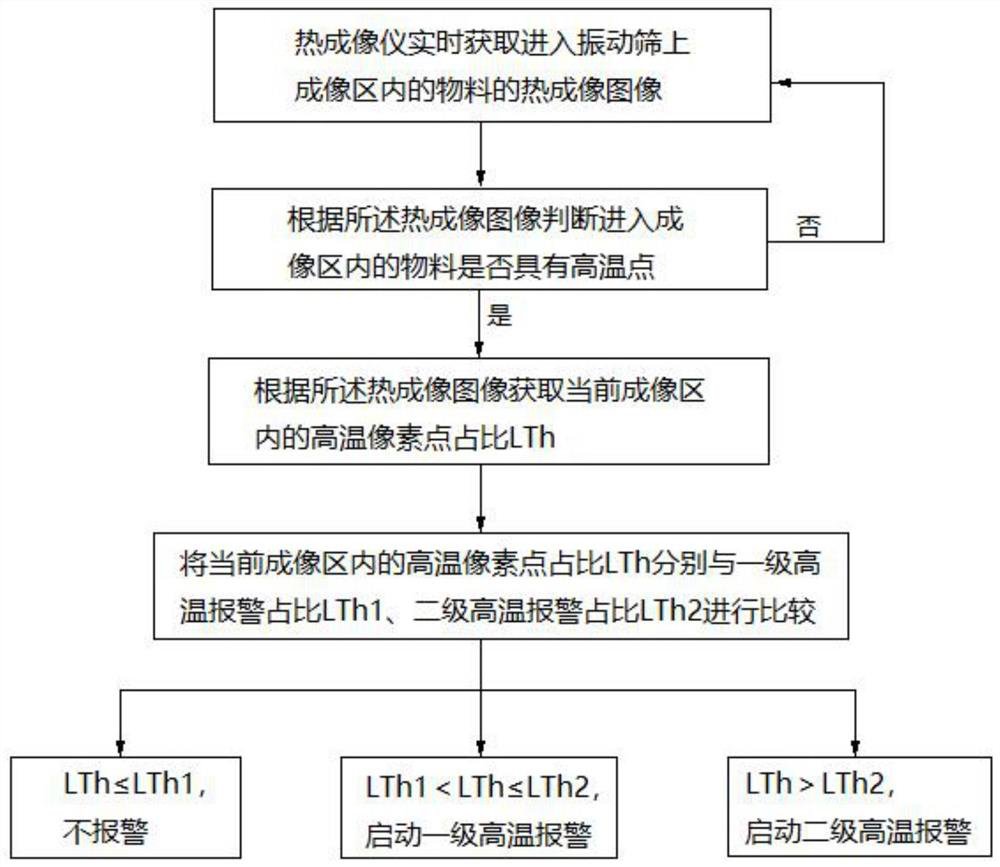

[0116] A method for activated carbon high temperature detection and grading alarm, the method comprises the following steps:

[0117] 1) The thermal imager 1 takes real-time pictures of the materials entering the imaging area 3 on the vibrating screen 2 to obtain a thermal imaging image;

[0118] 2) According to the thermal imaging image analysis, it is judged whether the material entering the imaging area 3 has a high temperature point;

[0119] 2a) If it is judged that the thermal imaging image does not have a high temperature point, return to step 1);

[0120] 2b) If it is judged that the thermal imaging image has a high temperature point, then obtain the proportion of high temperature pixel points in the current imaging area 3 according to the thermal imaging image;

[0121] 3) Compare the proportion of high-temperature pixels in the current imaging area 3 with the proportion of high-temperature pixels set for alarm, so as to judge the high-temperature state of the materi...

Embodiment 2

[0123] like image 3 Shown, a kind of activated carbon high temperature detection and the method for grading alarm, this method comprises the following steps:

[0124] 1) The thermal imager 1 takes real-time pictures of the materials entering the imaging area 3 on the vibrating screen 2 to obtain a thermal imaging image;

[0125] 2) According to the thermal imaging image analysis, it is judged whether the material entering the imaging area 3 has a high temperature point;

[0126] 2a) If it is judged that the thermal imaging image does not have a high temperature point, return to step 1);

[0127] 2b) If it is judged that the thermal imaging image has a high temperature point, then obtain the proportion of high temperature pixel points in the current imaging area 3 according to the thermal imaging image;

[0128] The high-temperature pixels are imaging points in the imaging area 3 whose temperature is higher than a set target temperature. Acquire the number n of high-tempera...

Embodiment 3

[0137] Repeat embodiment 2, but in step 2), it is judged whether the thermal imaging image has a high temperature point, specifically:

[0138] The highest temperature value T1 in the thermal imaging image is acquired, and the highest temperature value T1 is compared with the set target temperature T0. If T1≤T0, it is determined that the thermal imaging image does not have a high temperature point. If T1>T0, it is determined that the thermal imaging image has a high temperature point. The value of T0 is 400°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com