Optical cable stripping device

A technology of stripping device and optical cable, applied in the direction of light guide, optics, optical components, etc., can solve the problems of poor controllability of cutting depth, poor stripping effect, damaged optical fiber, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

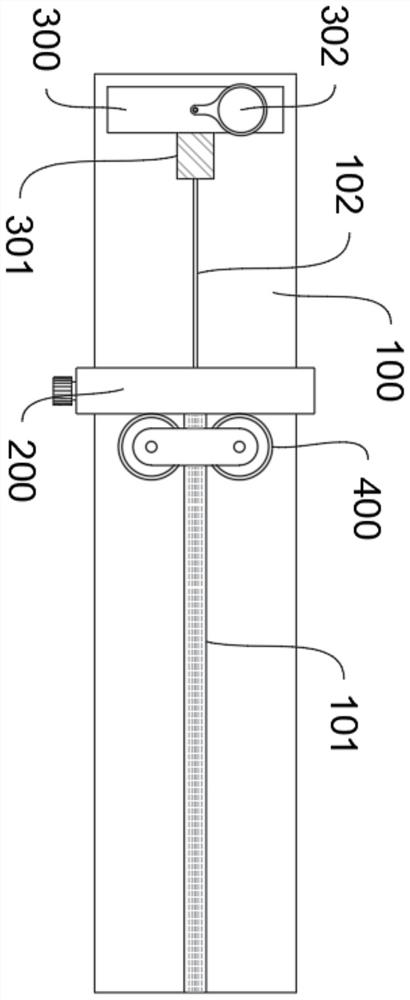

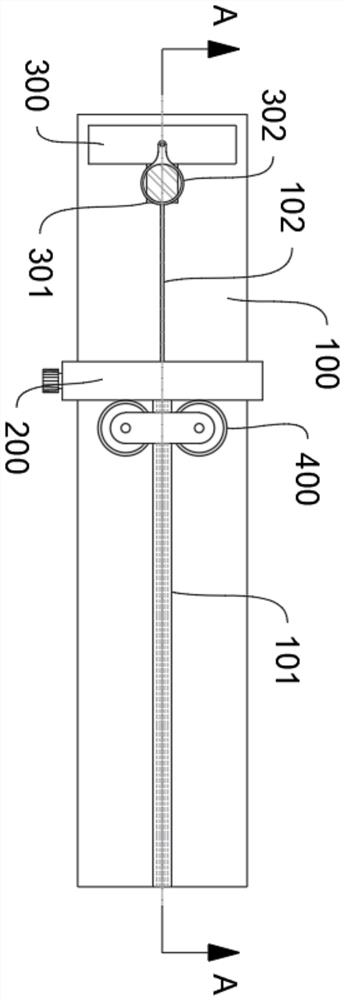

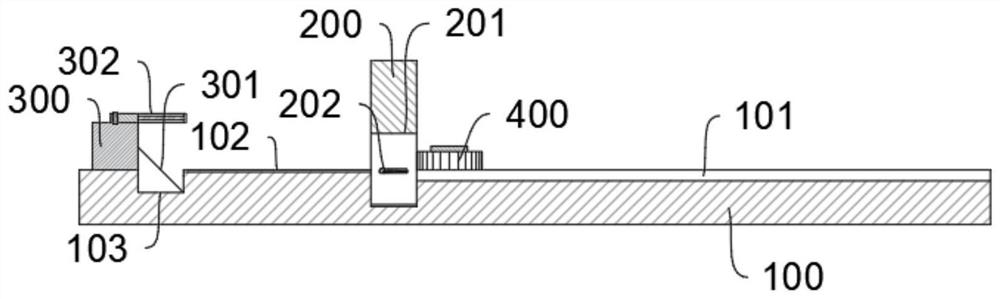

[0050] a kind of like figure 1 , figure 2 and image 3 The shown optical cable stripping device specifically includes:

[0051] The base 100, the base 100 is provided with a stripper 200 for stripping the cortex of the optical cable 500, and an observation assembly 300 for improving the stripping accuracy, the stripper 200 and the observation assembly 300 are fixedly arranged on the base 100;

[0052] The base 100 is provided with a cable inlet trough 101, the upper end of the cable inlet trough 101 is opened to place the optical cable 500, and extends from the edge of the base 100 to the wire stripper 200, and further a fiber outlet trough 102 can be set on the base 100, as shown in the present invention. The embodiment is provided with extending from the wire stripper 200 to the observation assembly 300;

[0053] The observation assembly 300 includes a platform, and the side of the platform facing the wire stripper 200 is provided with a reflective observation mirror 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com