Grounding bridging round steel machining device and method

A technology of round steel and bridging, which is applied in the direction of contact manufacturing and connecting contact materials, etc., can solve the problems of low efficiency, time-consuming and labor-intensive, etc., achieve high operating efficiency, increase the overall weight, and save construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

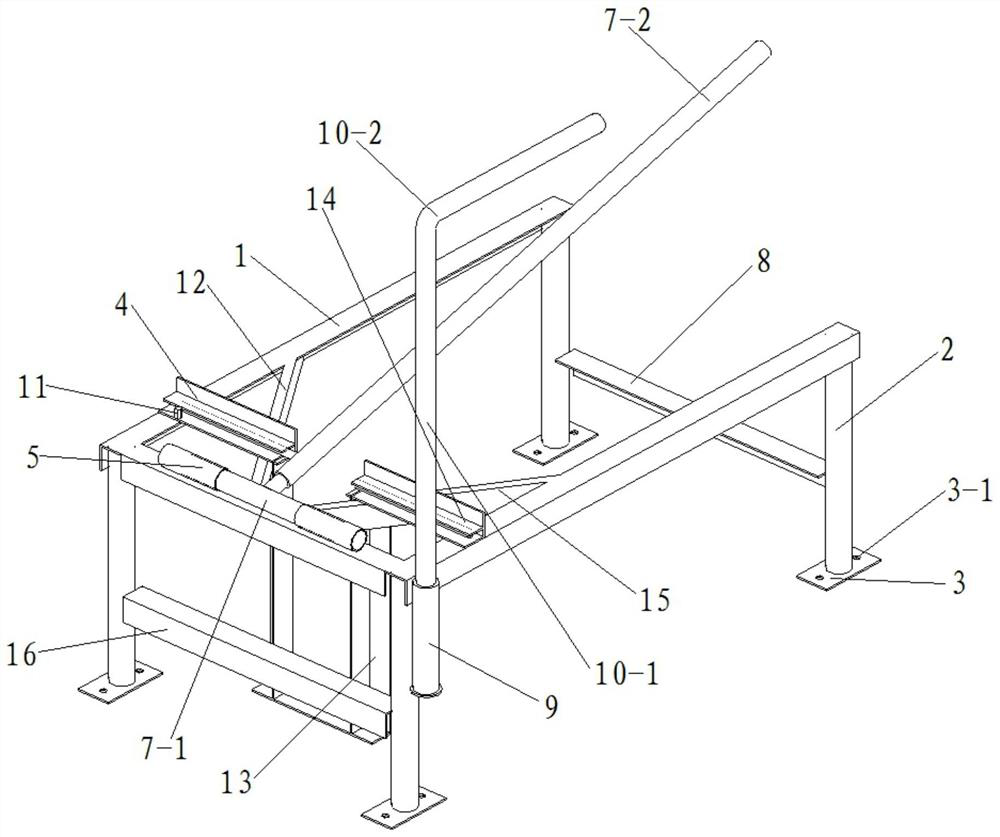

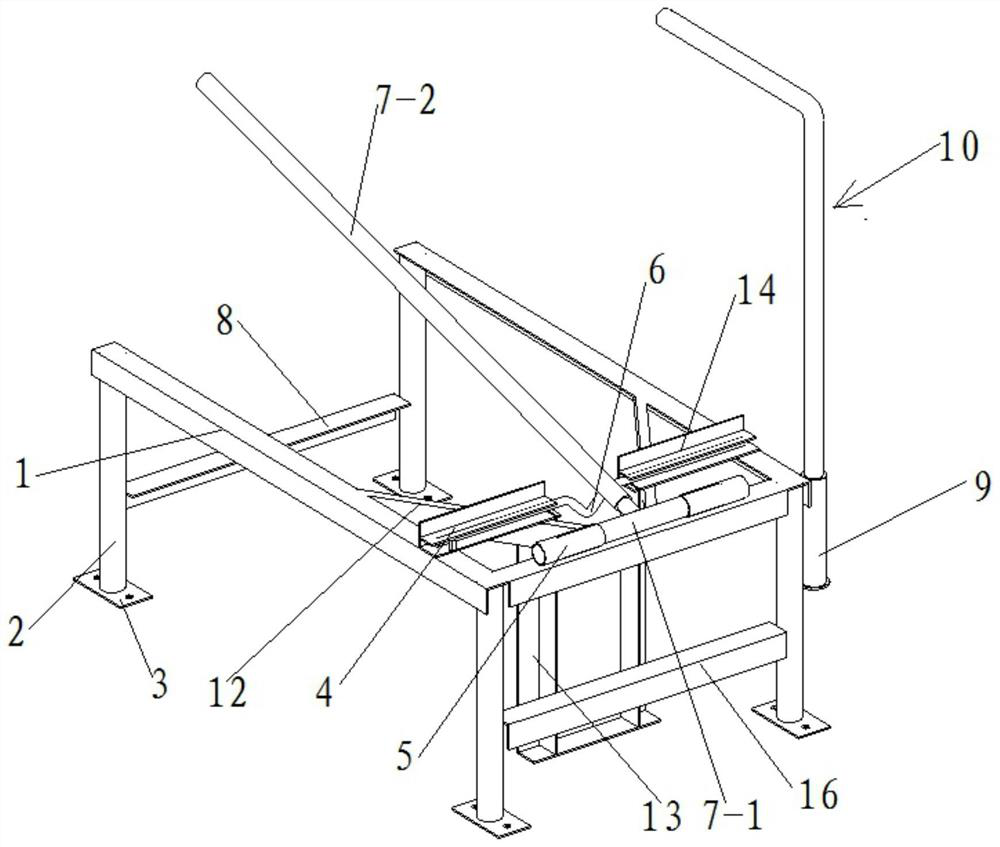

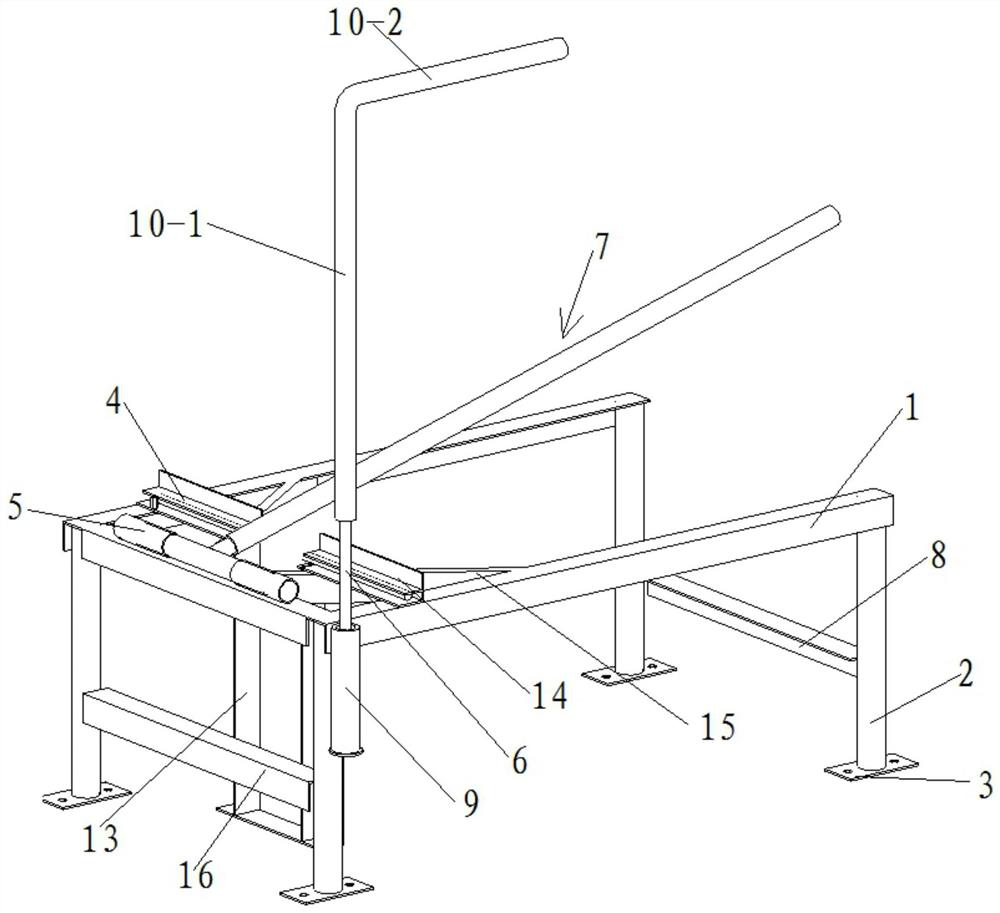

[0044] Such as Figure 1 to Figure 4As shown, the present invention includes a processing base arranged on the ground, a pressing mechanism arranged on the top of the processing base and pressing the round steel 6 to be processed, and a pressing mechanism arranged on one side of the processing base and bending the round steel to be processed 6 simmering mechanism;

[0045] The processing base comprises a horizontally arranged base frame 1 and a plurality of support legs 2 vertically arranged at the bottom of the base frame 1, and the structural dimensions of the plurality of support legs 2 are the same, and the base frame 1 and A plurality of supporting legs 2 are integrally formed;

[0046] The pressing mechanism includes a snap-fit assembly horizontally arranged on the top of the processing base, a support assembly arranged at the bottom of the snap-fit assembly for supporting the snap-fit assembly, and a support assembly arranged on the top of the processing base. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com