Hair drier with high wind speed

A hair dryer, high wind speed technology, applied in the direction of washing hair or scalp devices, clothing, hairdressing equipment, etc., can solve the problems of increasing energy consumption, occupying handle space, large volume, etc., achieving simple structure, improving air intake and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

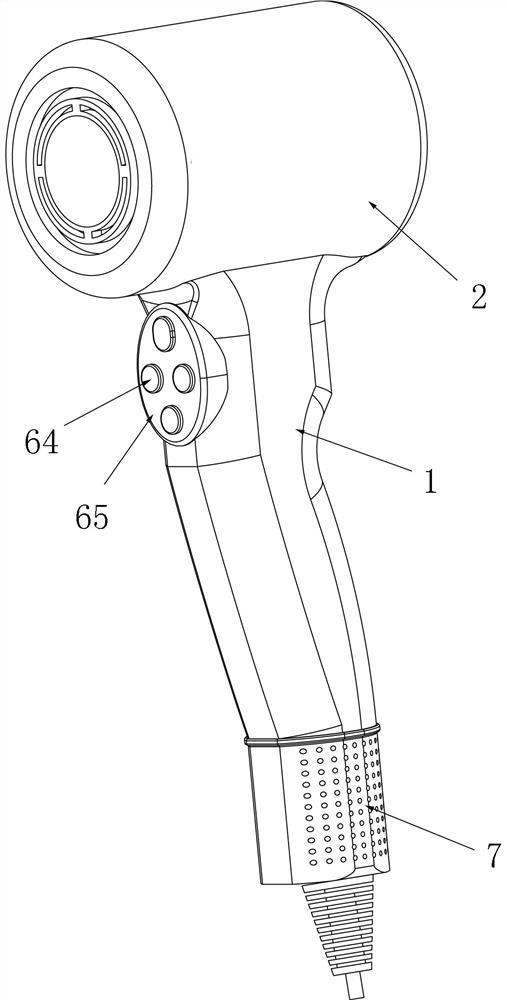

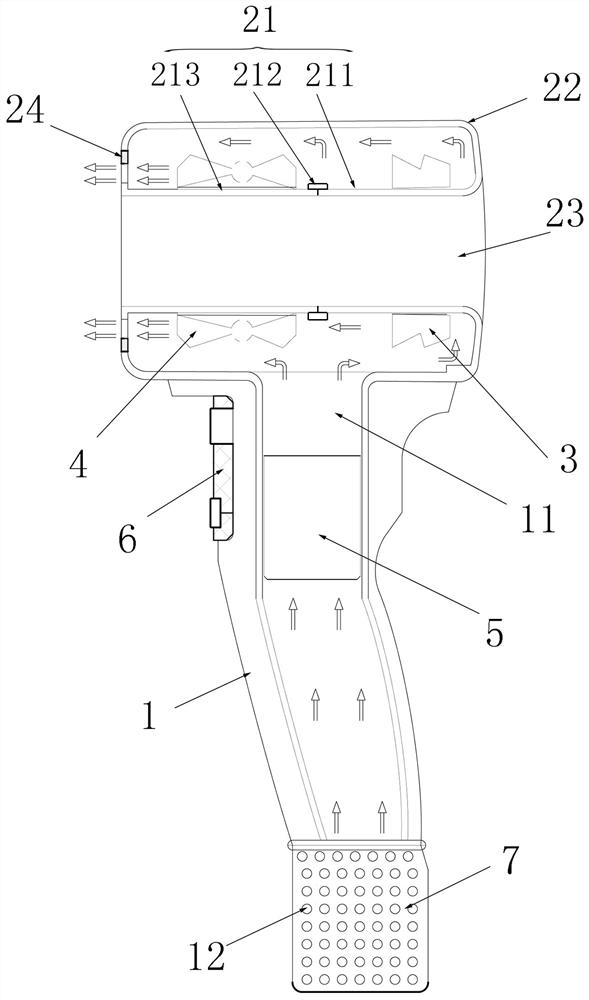

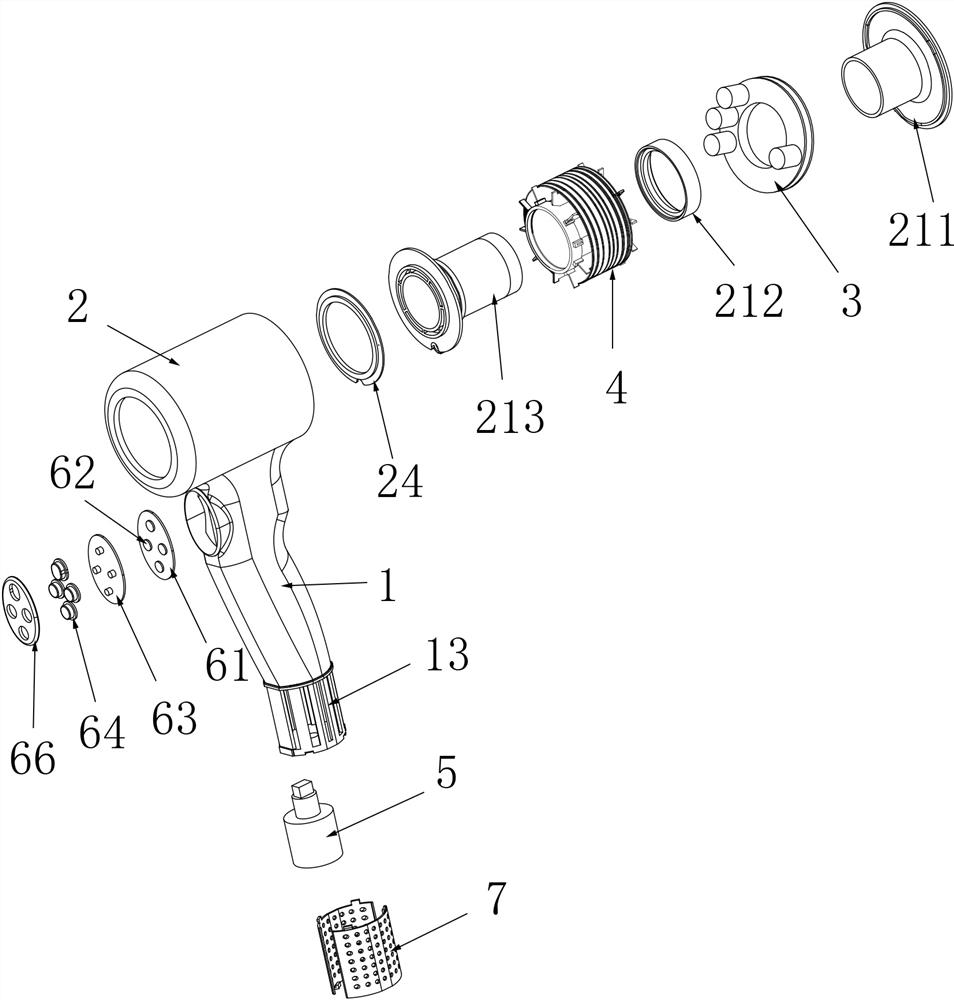

[0024] The hair dryer described in this embodiment includes a blower 2 and a handle 1, both of which are fixed as one. The air cylinder 2 includes an inner air duct 21 and an outer air duct 22 arranged coaxially, and the inner air duct 21 is composed of an air inlet inner pipe 211, a sleeve pipe 212 and an air outlet inner pipe 213 arranged coaxially, and the inner air inlet pipe 213 It is integrated with the air outlet inner pipe by a sleeve; an annular cavity 23 is formed between the outer wall of the inner air duct and the inner wall of the outer air duct, and the annular cavity 23 communicates with the inside of the handle 1; inside the annular cavity 23 There is also a control module 3 and a controllable heating element 4. The controllable heating element includes a tubular support and a heating wire wound on the support. The tubular support is set outside the air outlet inner tube 213. The control module 3 is a ring structure and is set on the inlet. On the outside of th...

Embodiment 2

[0031] The structure of this embodiment is similar to that of Embodiment 1, the difference is that: the end of the handle 1 is provided with a circular or elliptical air inlet pan 8 , and the bottom surface of the air inlet pan is a circular or elliptical filter screen 81 . When in use, the air enters directly from the bottom surface of the handle, and the air can be absorbed by the motor without changing the flow direction, so that the wind force of the hair dryer is stronger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com