Oil filtering device free of disassembly and washing

A filter device, a technology that does not need to be dismantled and washed, is applied in the field of oil filter devices, and can solve the problems of filter function failure, filter core rupture, damage to equipment, etc., and achieve the effect of simple mechanism, reduced filter cost, and high-efficiency filter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

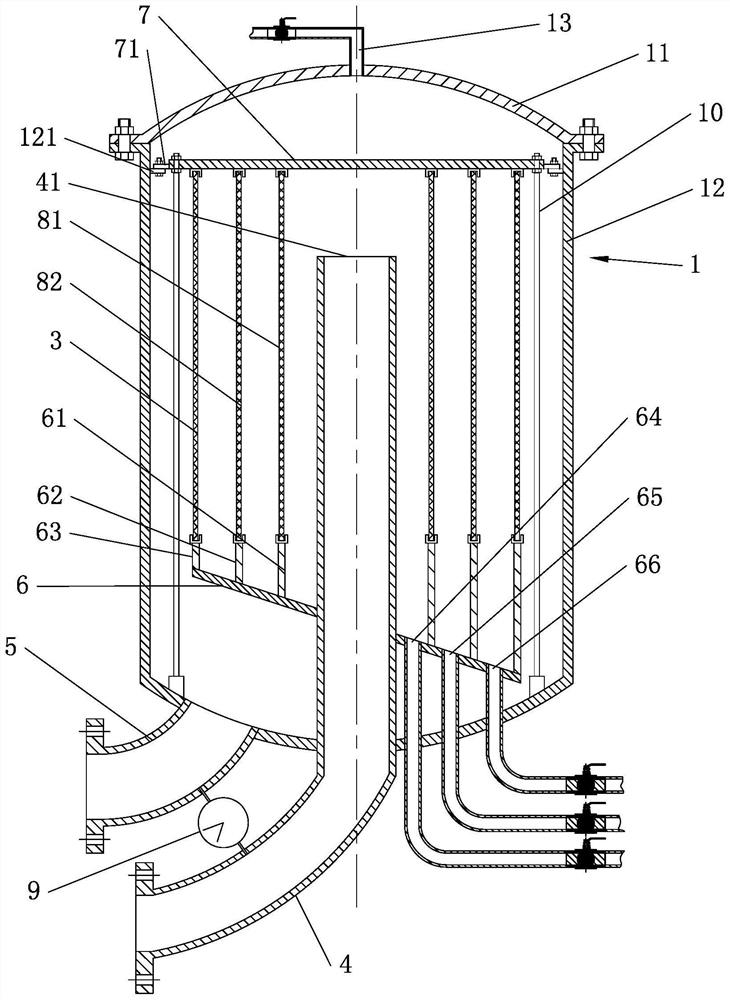

[0015] Such as figure 1 As shown, the non-removable and washable oil filter device of the present invention includes a housing 1 , a filter element, an oil inlet pipe 4 , an oil outlet pipe 5 and a differential pressure gauge 9 . The casing 1 includes a bucket body 12 and a bucket cover 11, and the bucket cover 11 is covered on the upper port of the bucket body 12 and is tightly connected by bolts. The upper end of the bucket cover 11 is provided with an exhaust pipe 13 equipped with a shut-off valve for exhausting the gas in the housing 1 . The oil inlet pipe 4 and the oil outlet pipe 5 are respectively connected with the housing 1, and the two ends of the differential pressure gauge 9 are respectively connected with the oil inlet pipe 4 and the oil outlet pipe 5, and are used for measuring the pressure difference between the oil inlet pipe 4 and the oil outlet pipe 5. The filter element is installed between the upper gland 7 and the bottom plate 6 in the housing 1 . The fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com