Photocuring filter element and preparation method thereof

A filter element and photo-curing technology, which is applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of difficult control of dimensional accuracy, labor-intensive, and complicated tooling for stacking aluminum partitions, so as to reduce health effects, The effect of reducing labor costs and prolonging the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

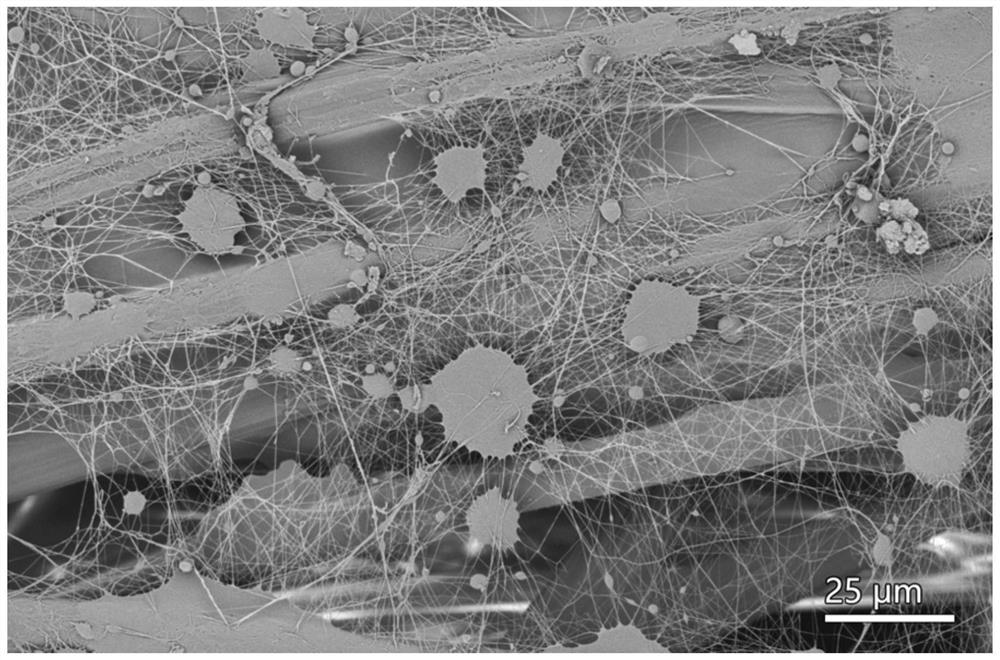

[0060] The invention provides a light-curing filter element, which includes an adsorption material, a coating material, a light-curing glue and an auxiliary agent. The inside of the coating material is filled with the absorption material, and the outside of the coating material is placed with light at a set interval. Curing glue; or use non-impregnated and impregnated light-curing glue to mix and spin the covering material; or light-curing glue is filled between the adsorption materials; or light-curing glue penetrates the adsorption material and connects with the surface of the covering material; Or the light-curing glue is pasted on the side of the coating material; or the above two or more combinations; the auxiliary agent is added to the adsorption material or coated on the outside of the light-curing glue. figure 2 It is the SEM picture of the cured glue on the side of the light-cured filter element of the present invention.

[0061] Wherein, the distance between the pho...

Embodiment 2

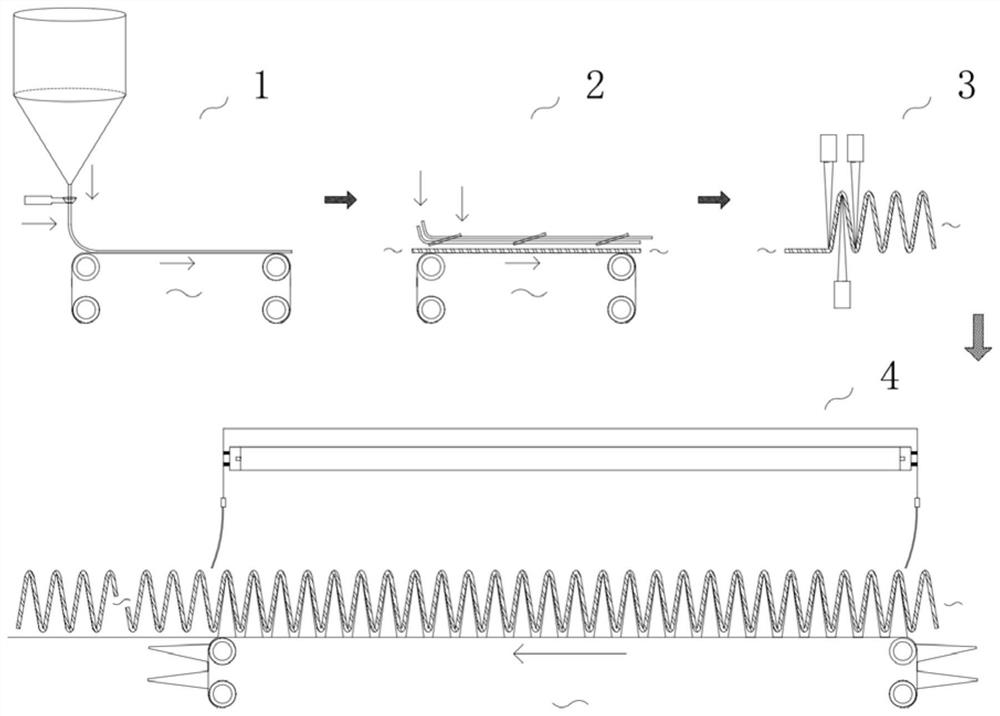

[0087] Such as figure 1 As shown, the present invention also provides a method for manufacturing a light-cured filter element, including: putting light-curable glue into the adsorption material, coating material, and auxiliary agent; Mold to obtain the desired photocurable filter element.

[0088] The process of placing the light-curing glue is as follows: extrude the tank and inject the light-curing glue into the light-transmitting film of the auxiliary agent, and seal the film in sections to form a paste (such as figure 1 In device 1), the paddles are placed in the adsorption material and the coating material in a set arrangement (such as figure 1 device 2); or the light-curing adhesive is directly placed in the adsorption material, coating material, and auxiliary agent in the form of a 3-15 Pa·s high-viscosity liquid.

[0089] Wherein, the extrusion flow rate is 2-200 mm / s, preferably, the flow rate is 10-40 mm / s. Select the appropriate flow rate according to the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com