Integrated pump station with waste gas purification function

A waste gas purification and functional technology, applied in the field of pumping stations, can solve the problems of inability to realize water flow heating, lack of water flow three-stage filtration ability, etc., and achieve the effects of convenient detection and maintenance, reliable connection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

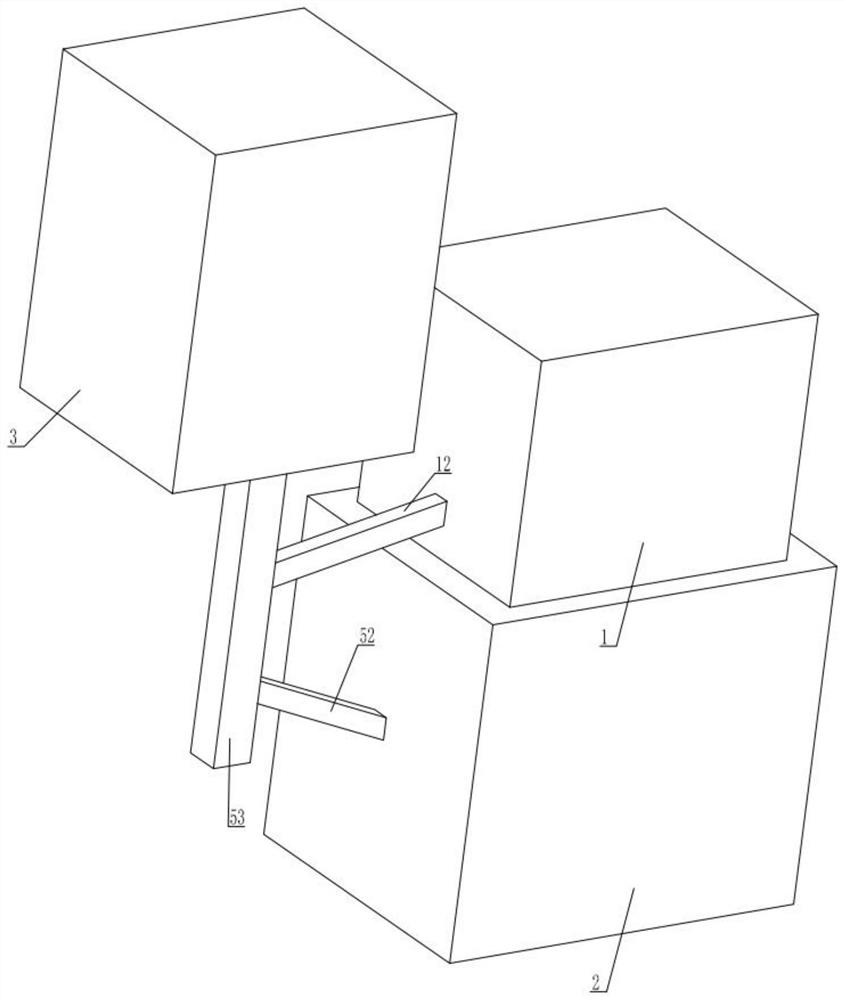

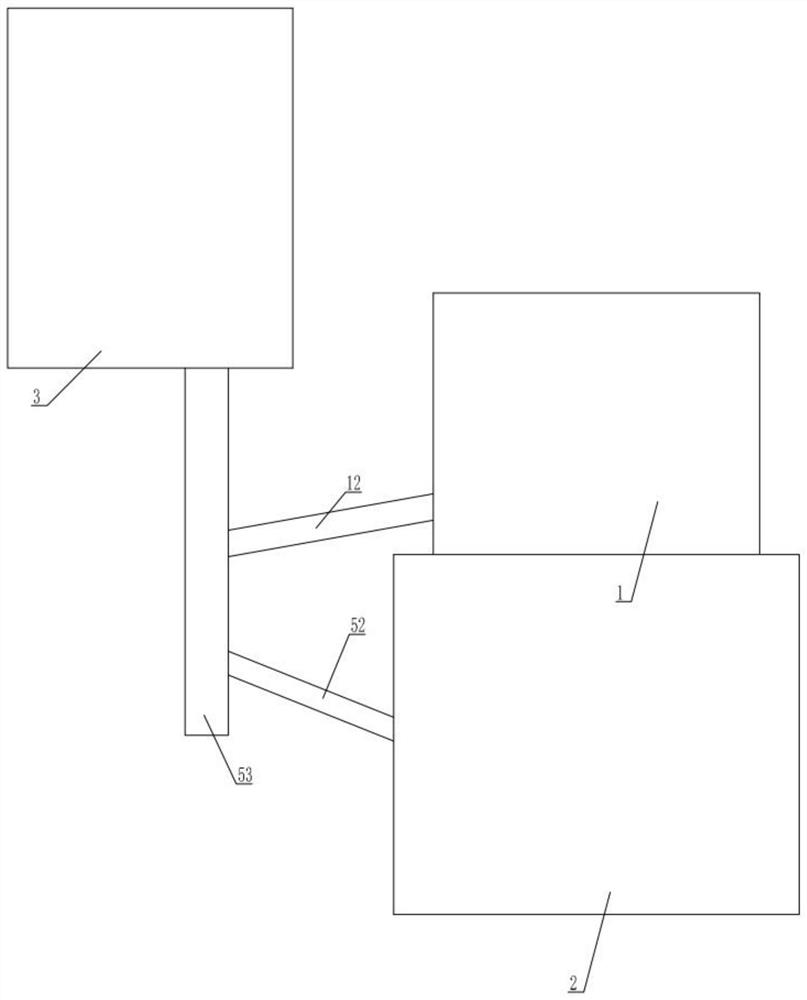

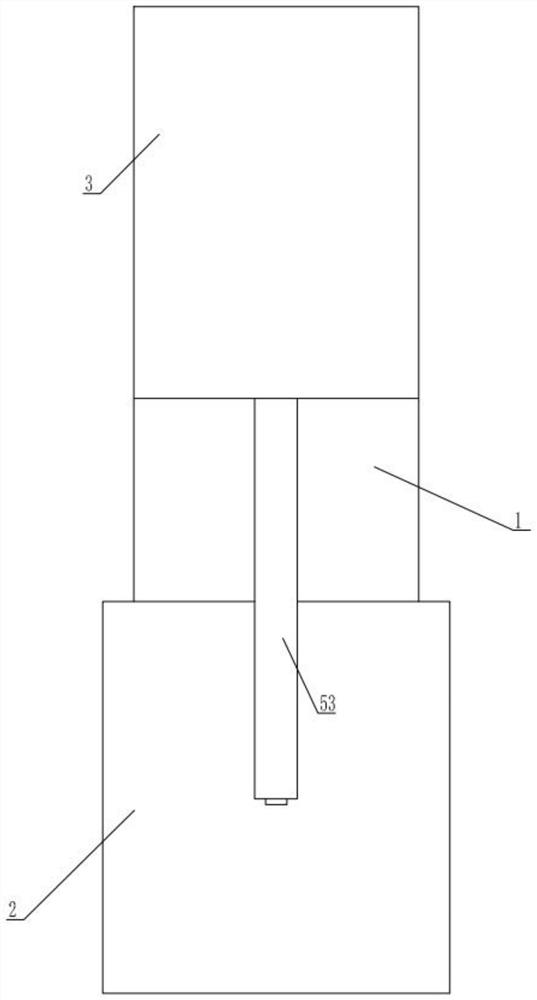

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

[0031] refer to Figure 1 to Figure 10 , an integrated pump station with exhaust gas purification function provided by the present invention includes a filter chamber 1, a combustion heating chamber 2, and an exhaust gas purification chamber 3. The inner upper surface of the filter chamber 1 is fixed with a motor bottom plate 4, and the A motor 5 is fixed on the lower surface of the motor bottom plate 4, and the lower power output end of the motor 5 is provided with a rotating shaft 6, and the bottom end of the rotating shaft 6 extends into the inside of the centrifugal box 14. The bottom end of the rotating shaft 6 is fixed with a centrifugal impeller 7, the inner lower surface of the centrifugal box 14 is fixed with a conical block 15, and the right part of the lower surface of the centrifugal box 14 is connected with the top of the second lower discharge pipe 16 Communicat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap