Drilling site practical operation simulation practical training platform

A training platform and on-site technology, applied in simulators, simulation devices of space navigation conditions, space navigation equipment, etc., can solve the problems of manual disassembly and cleaning, high work intensity, etc., to improve filtration efficiency, increase filtration area, use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

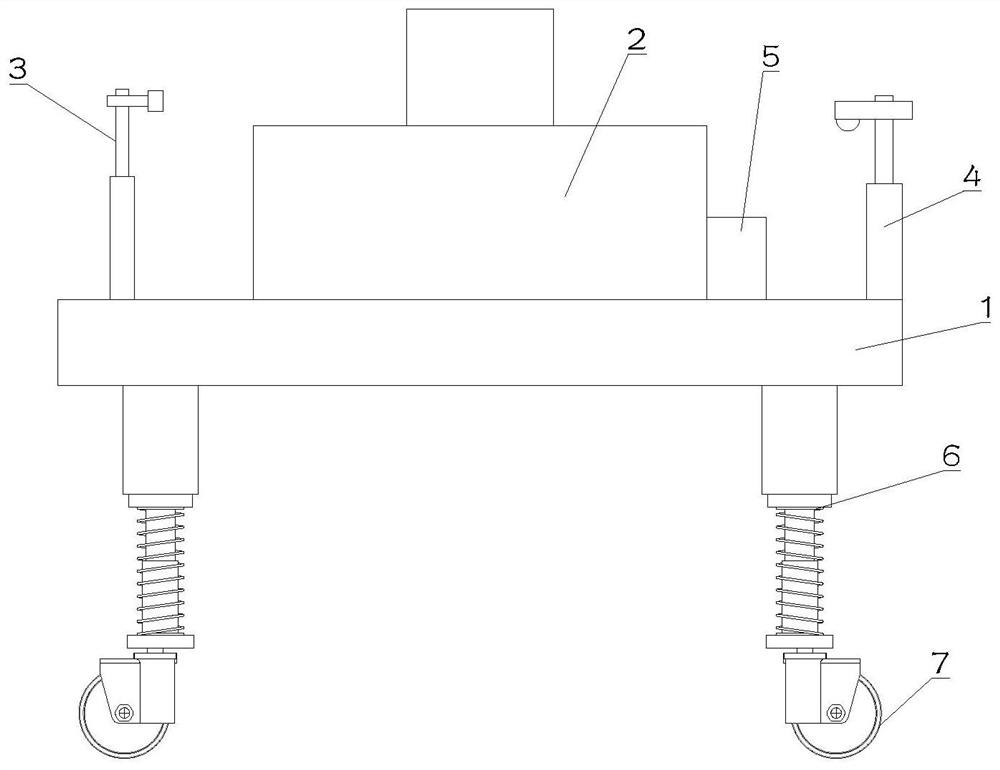

[0024] see Figure 1~3 , in Embodiment 1 of the present invention, it is a structural diagram of a drilling site practical operation simulation training platform provided by the embodiment of the present invention, including: a platform 1, a simulation operation machine 2 is fixedly installed on the platform 1, and the platform 1 removable settings;

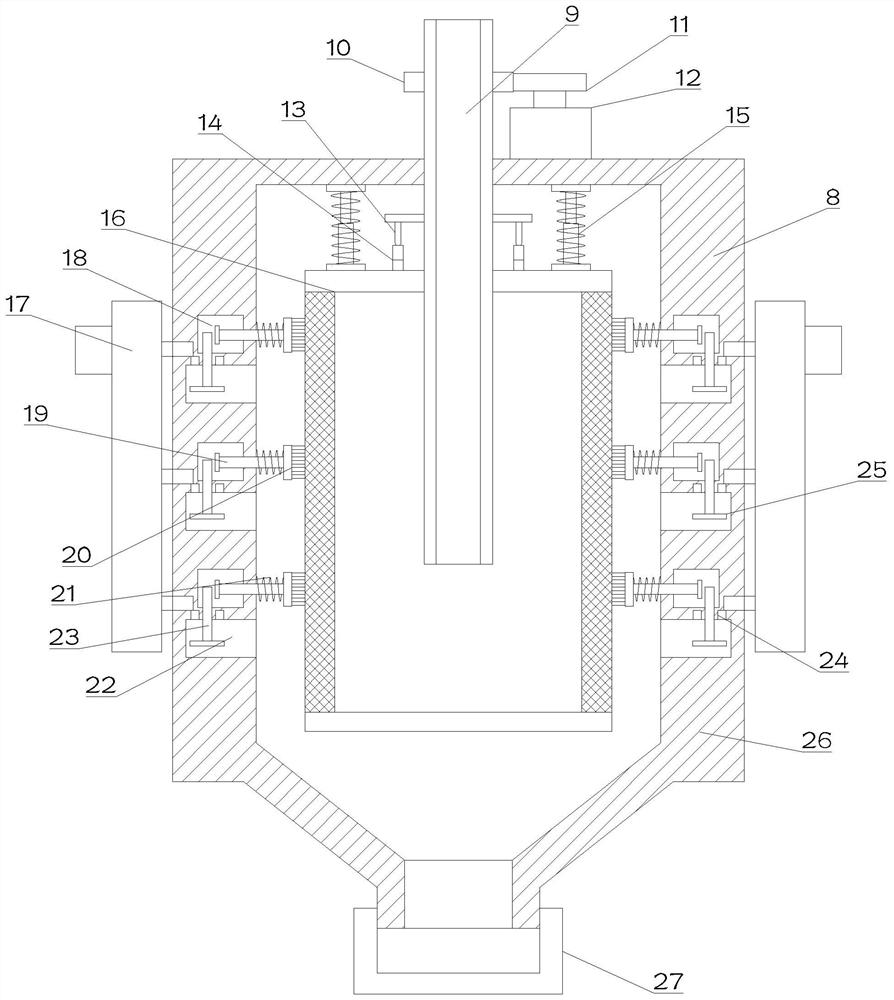

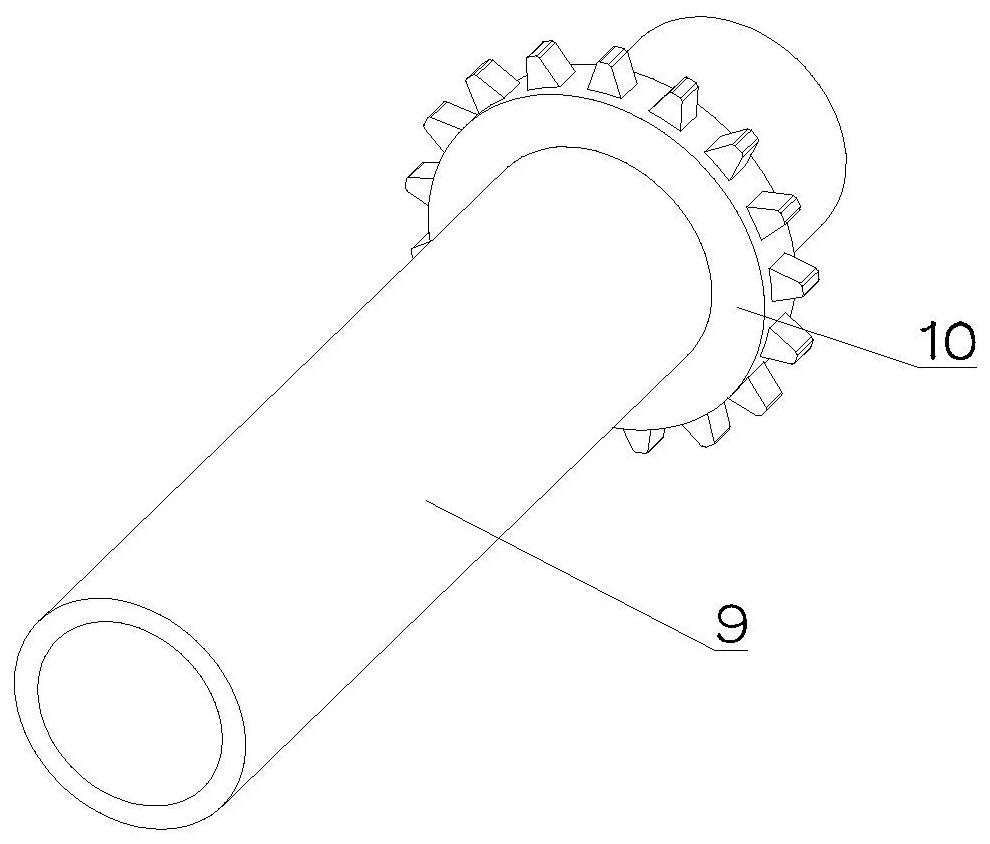

[0025] And, the dust removal component 8 fixedly installed on the platform 1, the dust removal component 8 includes a housing 26 with a cavity inside, and the inside of the housing 26 is elastically provided with a filter screen cylinder 16 up and down, and the filter screen cylinder 16 A plurality of brush assemblies are arranged in an array from top to bottom on the outside, and the brush assemblies are composed of a plurality of brushes 20 arrays; the brushes 20 are attached to the filter cylinder 16; A plurality of exhaust grooves 22 are provided, and the interior of the exhaust grooves 22 is provided with a driving mechanis...

Embodiment 2

[0028] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the drive mechanism includes a linkage chamber 18 disposed inside the housing 26, and a slide rod 19 and a connecting rod 23 are slidably provided inside the linkage chamber 18, and the slide The end of the rod 19 away from the linkage cavity 18 is fixedly installed on the brush 20, the sliding rod 19 is elastically arranged on the housing 26, the lower end of the connecting rod 23 is fixed with a driven plate 25, and the inner wall of the exhaust groove 22 is set There is an air injection port 24, the air injection port 24 is arranged opposite to the driven plate 25, the air injection port 24 communicates with the dust suction port 5, and a linkage medium is arranged inside the linkage cavity 18; specifically, when the air passes through the air injection port 24 Entering the inside of the exhaust groove 22, the driven plate 25 is under the pressure of the air, so that the driven pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap