Batch grinding equipment for cutting edges of mechanical cutters

A batch grinding and cutting tool technology, applied in grinding/polishing equipment, metal processing equipment, other manufacturing equipment/tools, etc., can solve the problems of low grinding accuracy and low efficiency of grinding devices, so as to improve grinding efficiency and improve the overall The effect of working efficiency and reducing the probability of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

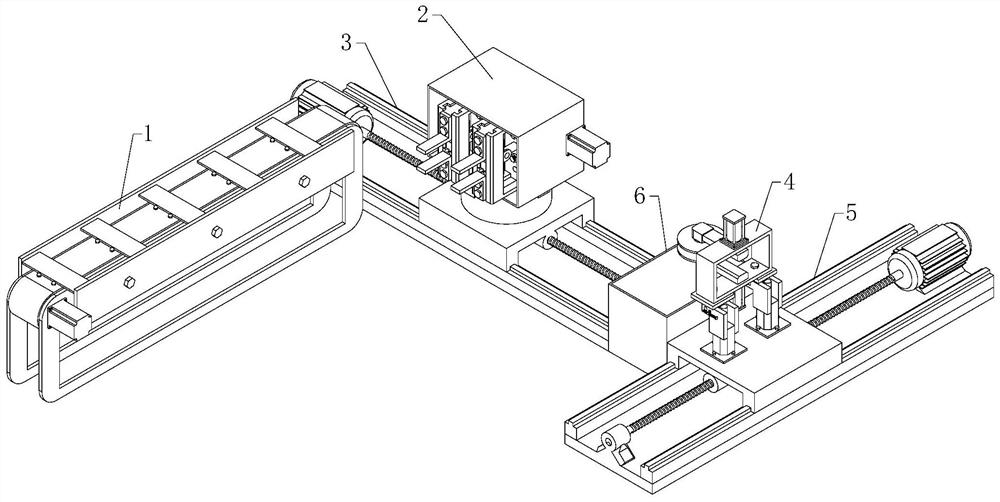

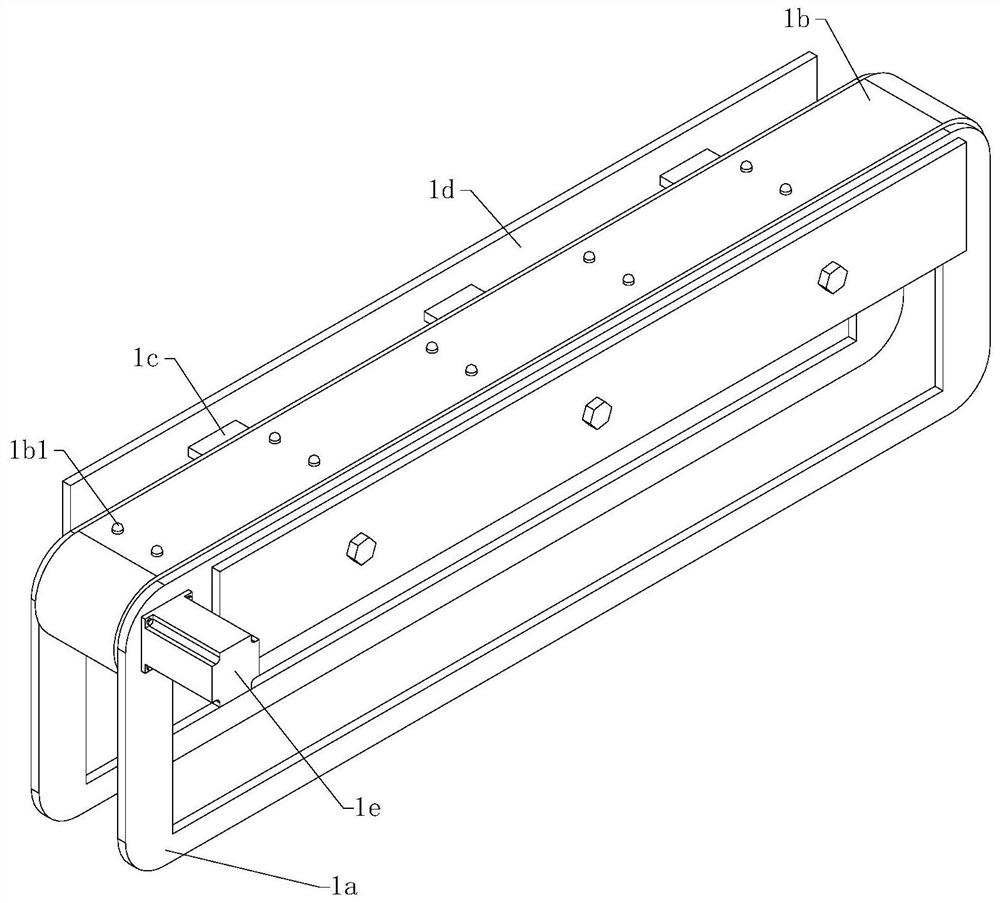

[0079] as 1 to Figure 10 As shown, a batch grinding equipment for mechanical knife blades includes a feeding device 1;

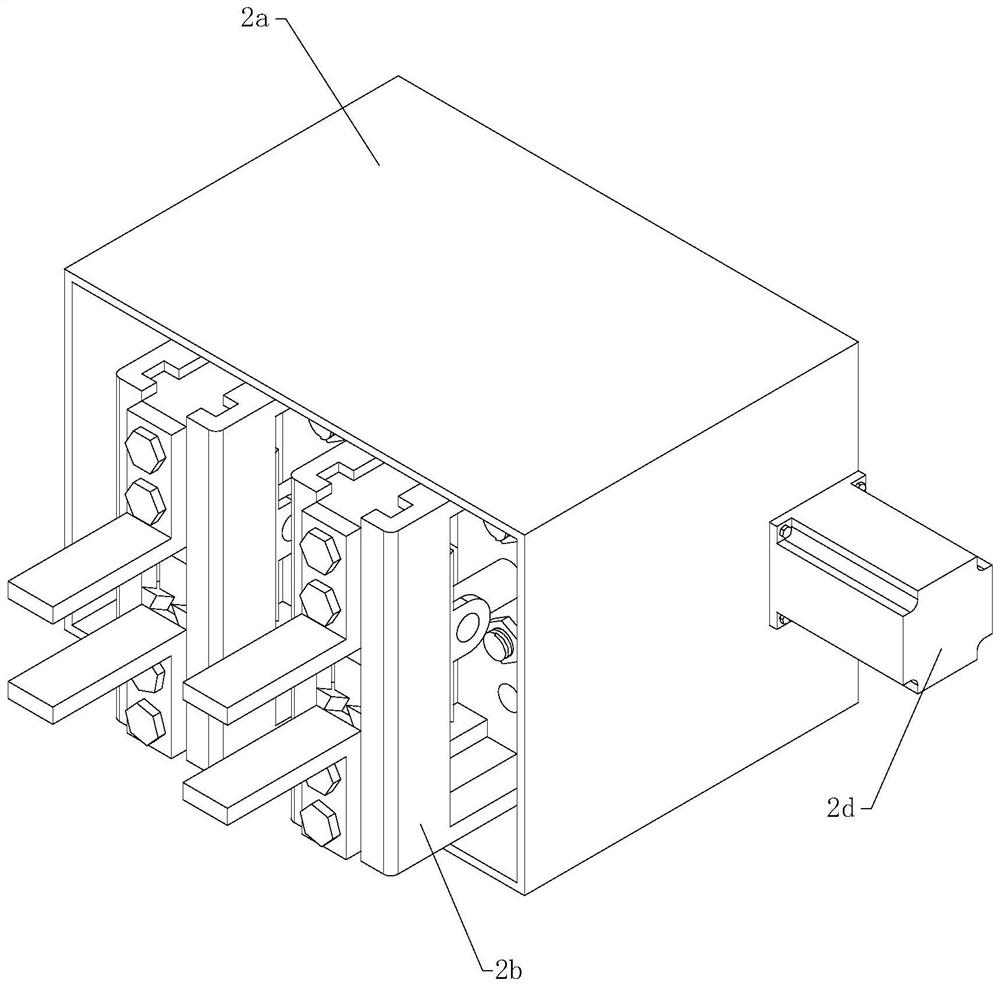

[0080] The gripping device 2 is arranged on one side of the output end of the feeding device 1, and the gripping end of the gripping device 2 faces a direction close to the feeding device 1;

[0081] The No. 1 mobile device 3 is arranged on one side of the output end of the feeding device 1, the clamping device 2 is fixed on the No. 1 mobile device 3, and the No. 1 mobile device 3 and the feeding device 1 are vertically distributed;

[0082] Grinding device 4, the grinding end faces the direction close to the feeding device 1;

[0083] No. 2 mobile device 5 is arranged on No. 1 mobile device 3 at an end away from feeding device 1, No. 2 mobile device 5 is vertically distributed with No. 1 mobile device 3, and polishing device 4 is fixed on No. 2 mobile device 5;

[0084] The collection box 6 is arranged between the No. 1 mobile device 3 and the No. 2 mobi...

Embodiment 2

[0126] Compared with Embodiment 1, in this embodiment, as shown in 9, the grinding device 4 includes a grinding device housing 4a, which is in the shape of a rectangular sleeve as a whole, and the grinding device housing 4a is fixedly arranged on No. 2 mobile device 5. The grinding device There are through holes with the same position on the two parallel sides of the shell 4a;

[0127] Grinding machine 4b, the grinding end is arranged on the outside of the grinding device shell 4a and faces the direction close to the clamping device 2, and the other end is set inside the grinding device shell 4a, and the number of the grinding machine 4b is set to two and mutually in a mirror image distribution;

[0128] No. two cylinder 4c is fixed on the outer wall of the grinding device housing 4a, and the piston rod points to the inside of the grinding device housing 4a, and the end of the piston rod away from the second cylinder 4c is fixedly connected with the other end on the grinding ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com