Double-machine driving type walking device for coal mine overhead rail type inspection robot and using method of double-machine driving type walking device

A technology for inspection robots and walking devices, which is applied in manipulators, manufacturing tools, etc., can solve problems such as high-frequency vibrations easily generated by the running of walking devices, variable walking paths of inspection robots, and affecting robot image acquisition, etc., to achieve long-distance The effect of inspection, light weight and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

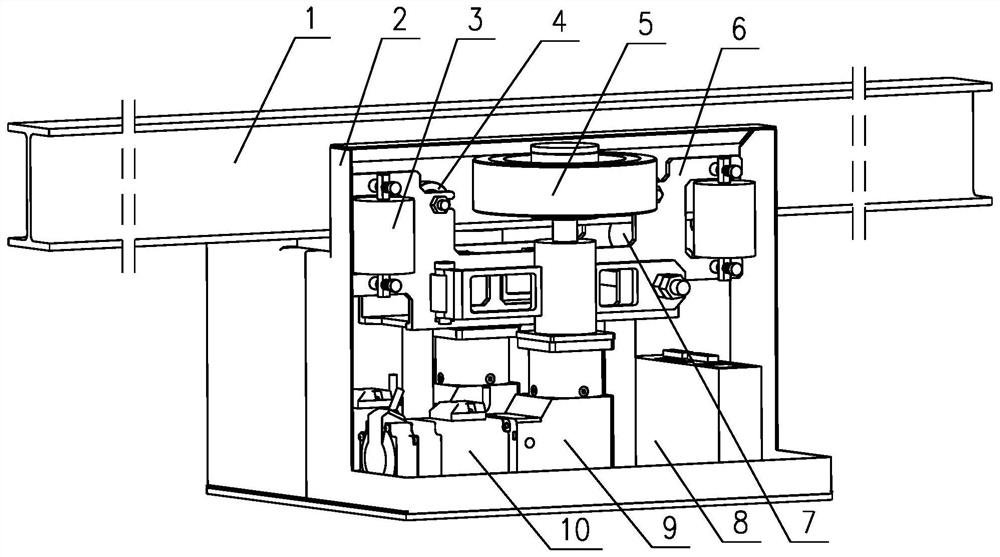

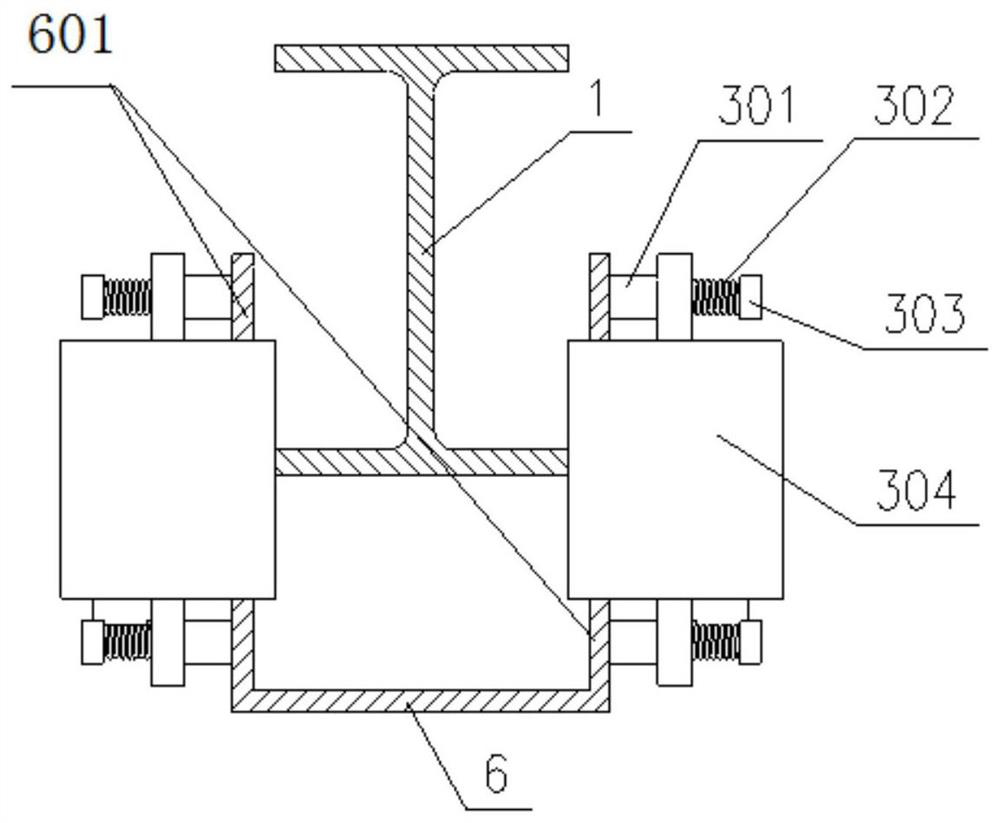

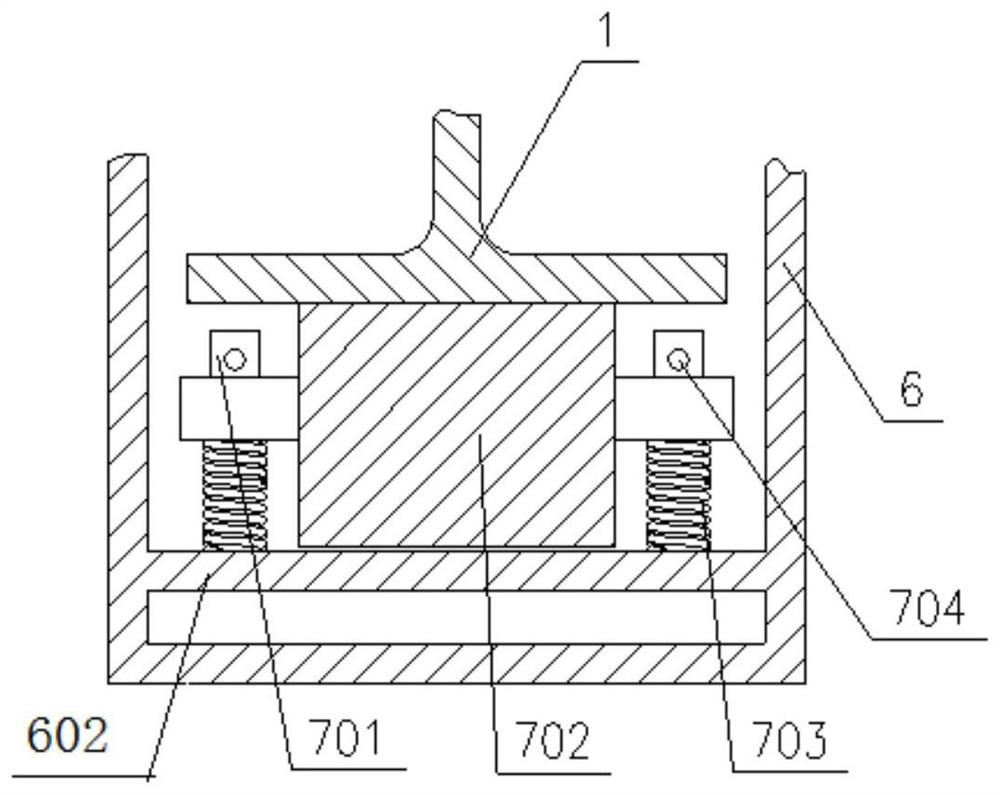

[0039] Refer Figure 1 - Figure 6 with Figure 10, Coal mine tag patrol robot with two-machine drive type walking device, the walking device walks along the work-by-side steel guide rail, the coal mine rim patrol robot is used for the driving type traveling device including the outer casing 2, the travel bracket 6 4 sets of transverse auxiliary wheel assemblies 3, 4 groups of heavy wheel assemblies 4, 2 sets of drive wheel assemblies 5, 2 sets of longitudinal auxiliary wheel assemblies 7, 1 controller 8, 2 decelerator 9 and 2 servo motor 10; The row take-away bracket 6 is mounted above the outer casing 2, and the vertical connecting frame 601 disposed in parallel to the walking bracket 6 is mounted on the vertical connection frame 601, respectively, and the lateral auxiliary wheel assembly 3, 2 groups of horizontal auxiliary wheel assemblies 3 in the front and rear direction, respectively. On the main zwang guide rail 1, the inner side of the two vertical connecting frames 601 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com