High-stability bag extruding and expanding equipment

A high-stability, high-equipment technology, applied in the field of auto parts processing, can solve the problems of low processing efficiency and poor quality of nylon tube extrusion, and achieve the effect of reasonable structure, easy operation and optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0025] Specific embodiments of the invention will be described in detail below.

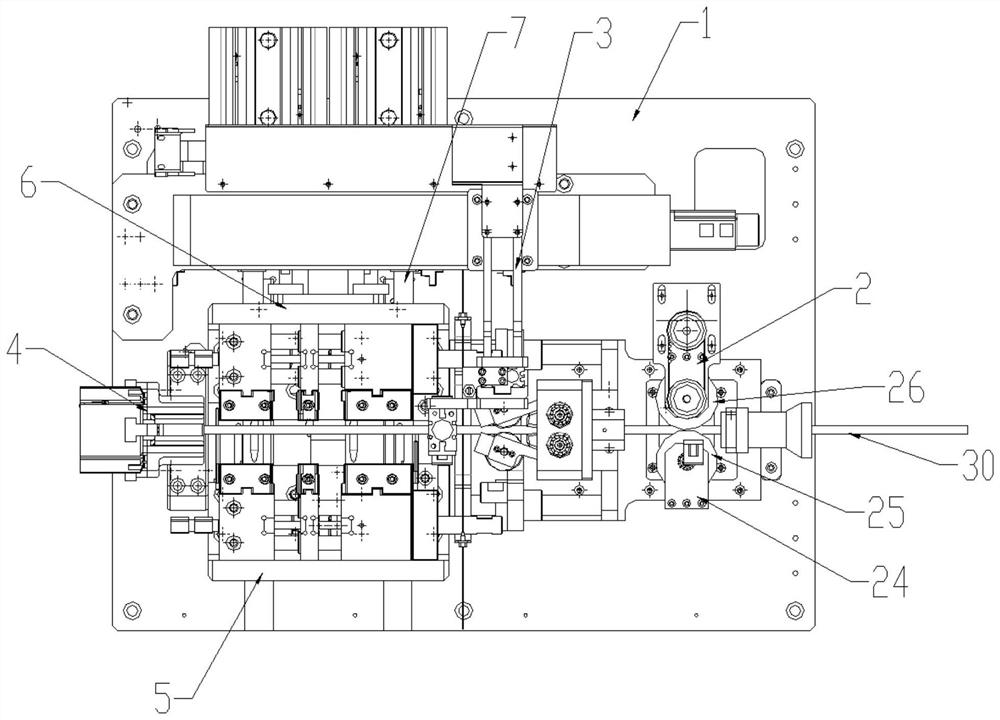

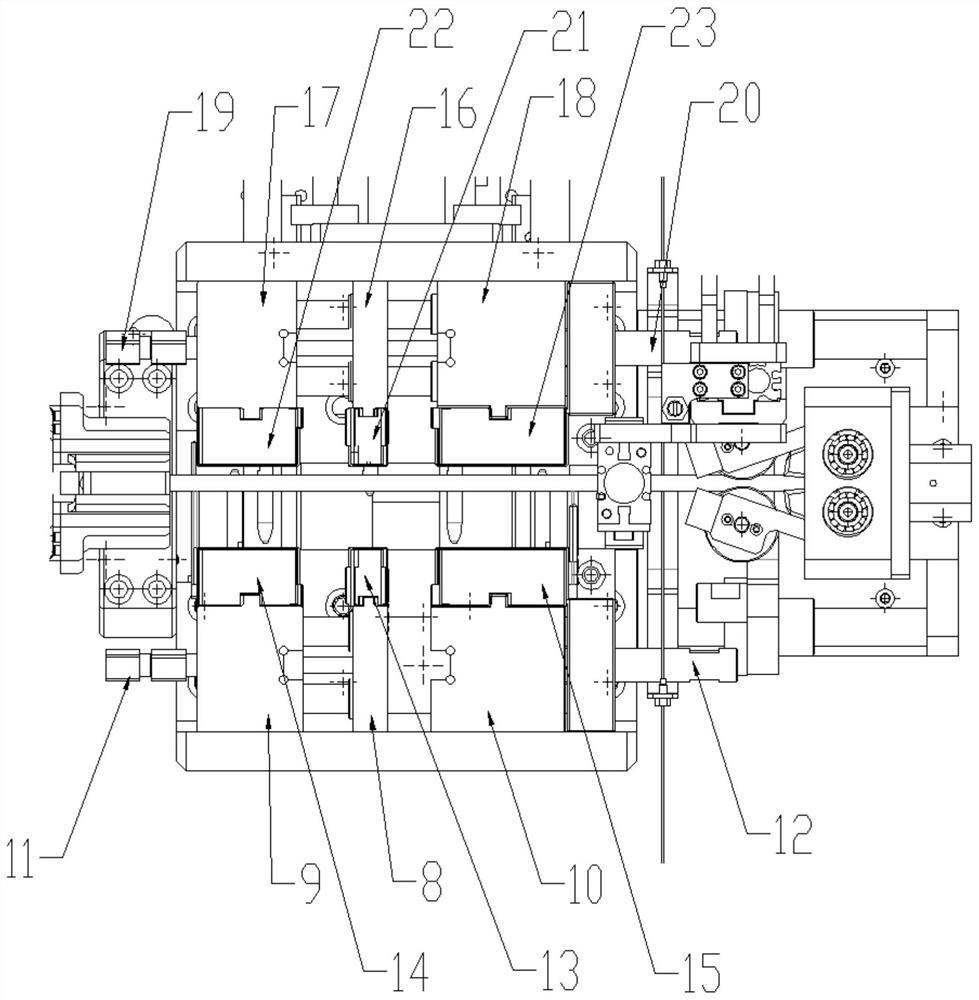

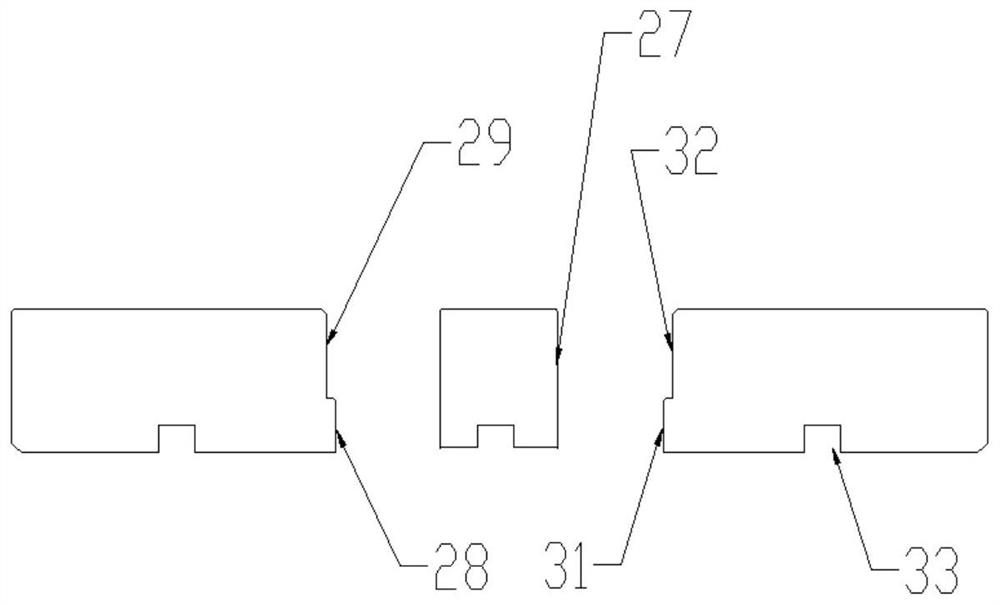

[0026] A high-stability squeeze bag equipment, such as Figures 1 to 4 As shown, it includes a base station 1, on which a transmission assembly 2 and a card loading assembly 4 are sequentially arranged; in an optional embodiment, in order to improve the degree of mechanical automation, the transmission assembly 2 and the card loading assembly 4 can Arrange the manipulator assembly 3;

[0027] A squeeze device is provided between the manipulator assembly and the clamping assembly, and the squeeze device includes a lower base 5, an upper base 6, and a Y-direction drive mechanism 7 for adjusting the distance between the upper and lower bases; specifically, A set of Y-direction drive mechanisms may be provided at the lower base 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com