Corrugated carton grooving and tapping machine

A corrugated box and hole punching machine technology, which is applied in the field of corrugated paper processing, can solve the problems of corrugated box damage and wrinkles, increase the cost of corrugated box hole opening, reduce equipment use occasions, etc., so as to avoid wrinkles and damage, and improve the success of hole opening. rate, the effect of increasing the use of occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

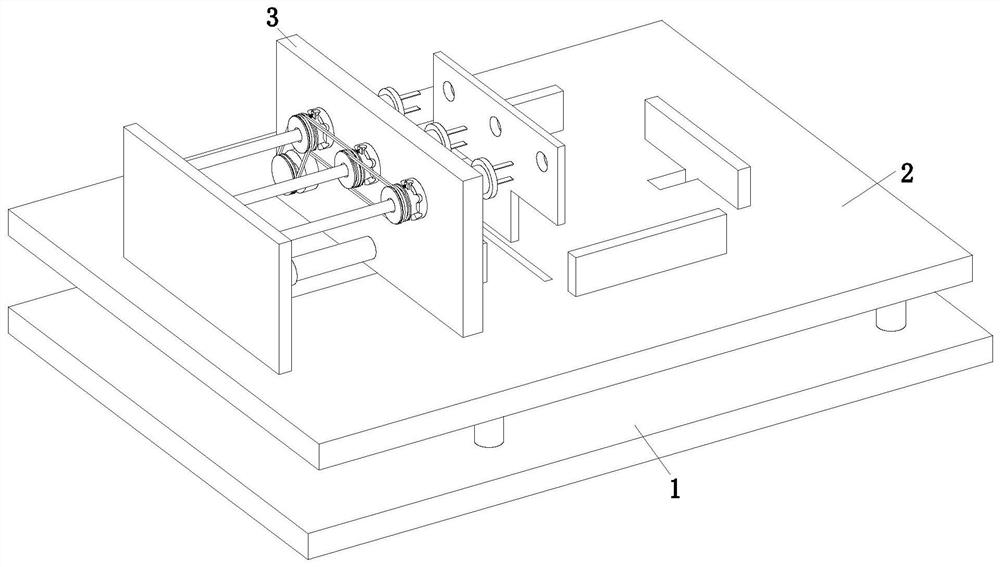

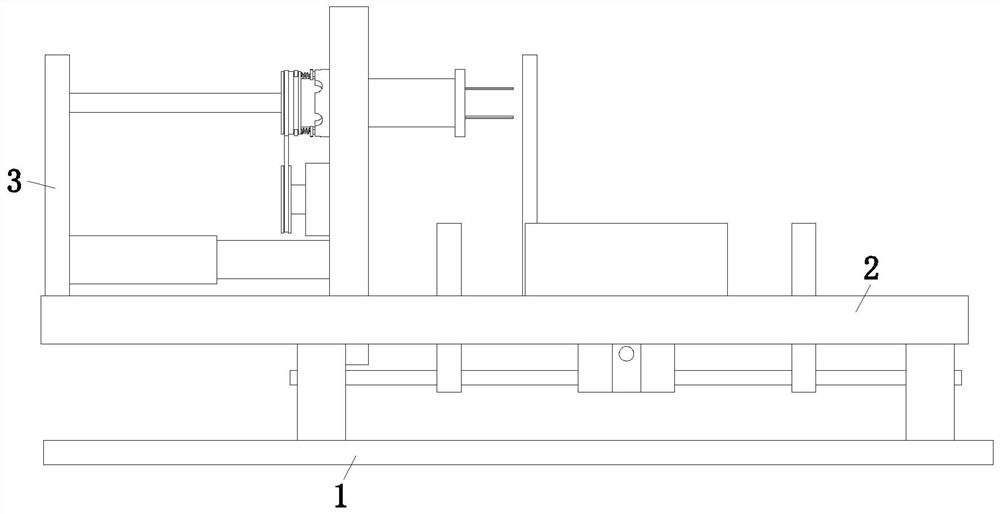

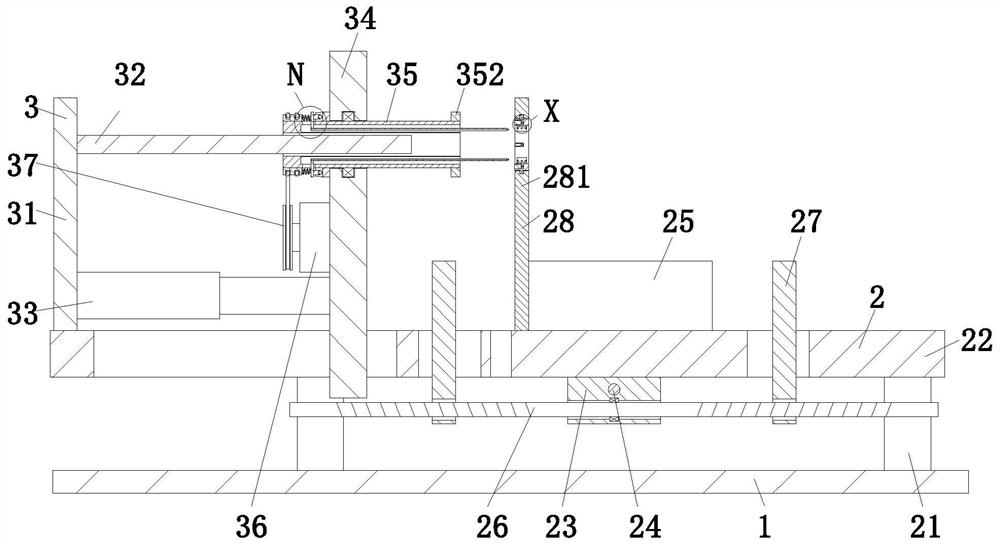

[0029] Such as Figure 1 to Figure 6 As shown, a corrugated box slotting machine includes a bottom plate 1, a placement device 2 and a hole opening device 3, the bottom plate 1 is equipped with a placement device 2, and the placement device 2 is equipped with a hole opening device 3.

[0030] The placement device 2 includes a support column 21, a placement plate 22, an auxiliary block 23, an upper screw 24, a positive splint 25, a lower screw 26, a side splint 27 and a cleaning mechanism 28. The upper end of the base plate 1 is evenly equipped with a plurality of Support column 21, the upper end of the support column 21 is equipped with a placement plate 22, the lower end of the placement plate 22 is equipped with an auxiliary block 23, the interior...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap