Blocking detection device for blanking pipe of bulk material conveyor

A technology of detection device and drop tube, which is applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc. It can solve the problems of detection device shaft damage, uneven accumulation, damage to coal conveying equipment, etc., and achieve accurate detection and response Sensitive, ensure personal safety, improve the effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

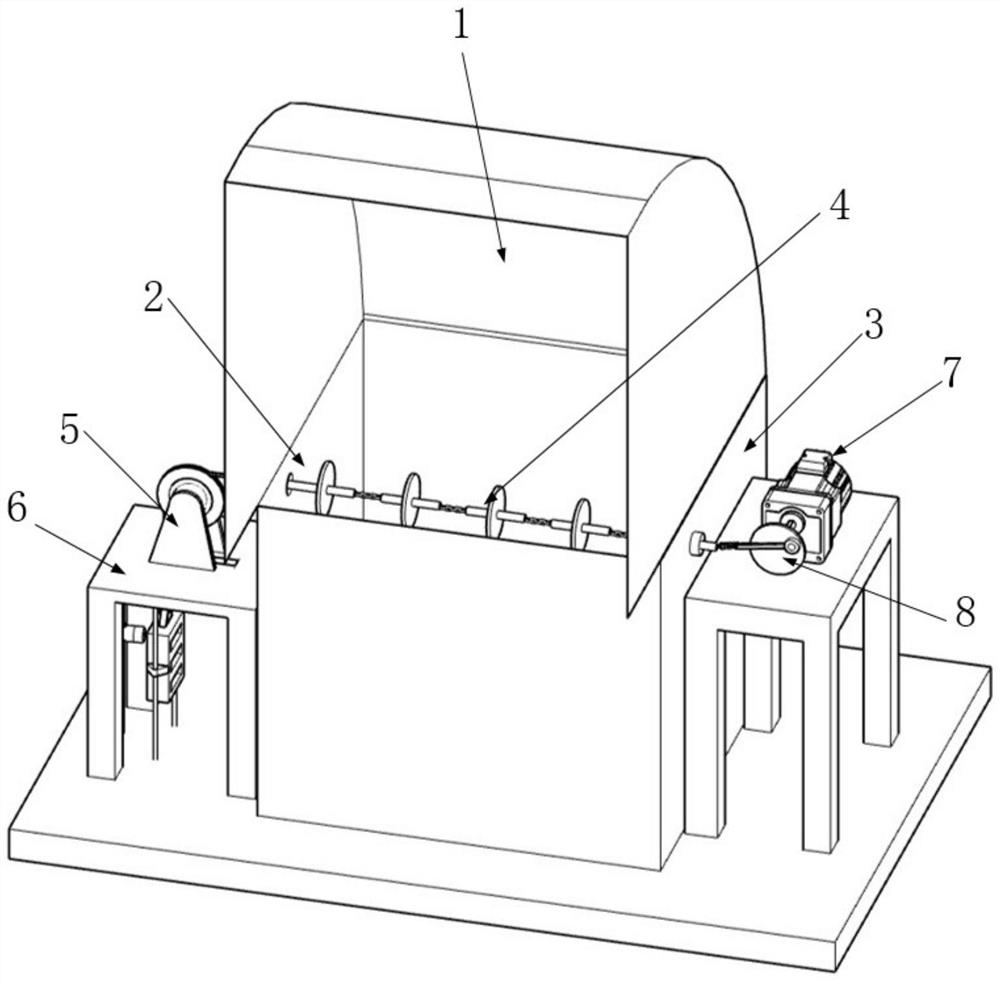

[0035] The invention relates to a material blocking detection device for a bulk material conveyor drop pipe, which is used to detect whether the material drop pipe 1 is blocked. like figure 1 As shown, the drop tube 1 includes a first side plate 2 and a second side plate 3 which are arranged oppositely, and also includes two front and rear side plates which are respectively perpendicular to the first side plate and the second side plate.

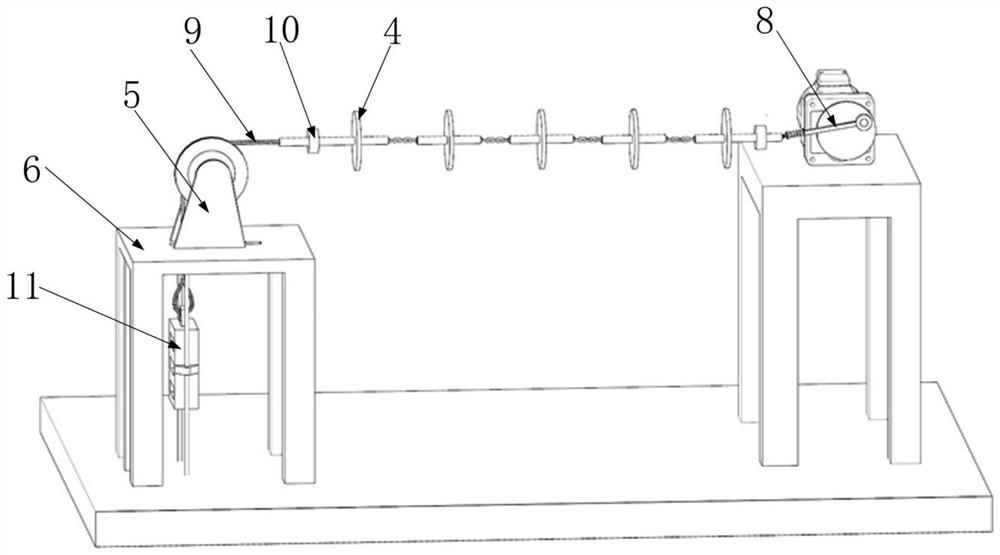

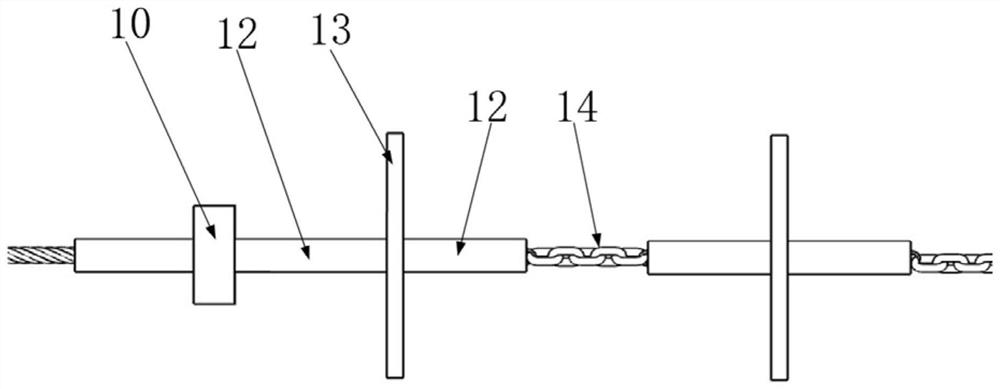

[0036] like figure 2 As shown, the blockage detection device of the present invention includes a detection chain arranged in the discharge pipe 1, a reciprocating drive assembly for driving the detection chain to reciprocate, and a movement sensor assembly for detecting the moving state of the chain, and one end of the detection chain It passes through the first side plate 2 and connects with the reciprocating drive assembly, and the other end passes through the second side plate 3 and connects with the movement sensing assembly. 4 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com