Stacked plate separating device and method

A separation device and stacking board technology, which is applied in the stacking, transportation and packaging of objects, and the unstacking of objects, etc., can solve the problem of unsatisfactory separation effect, achieve the effect of easy separation and reduce the adhesion of boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

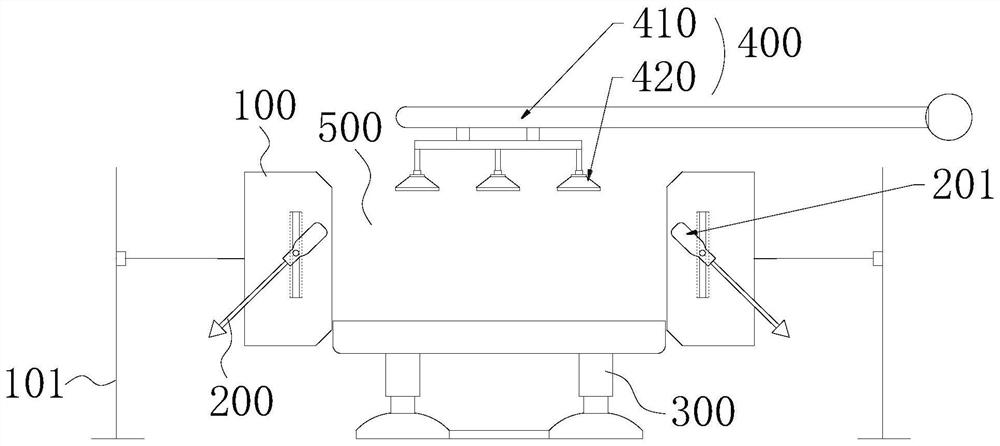

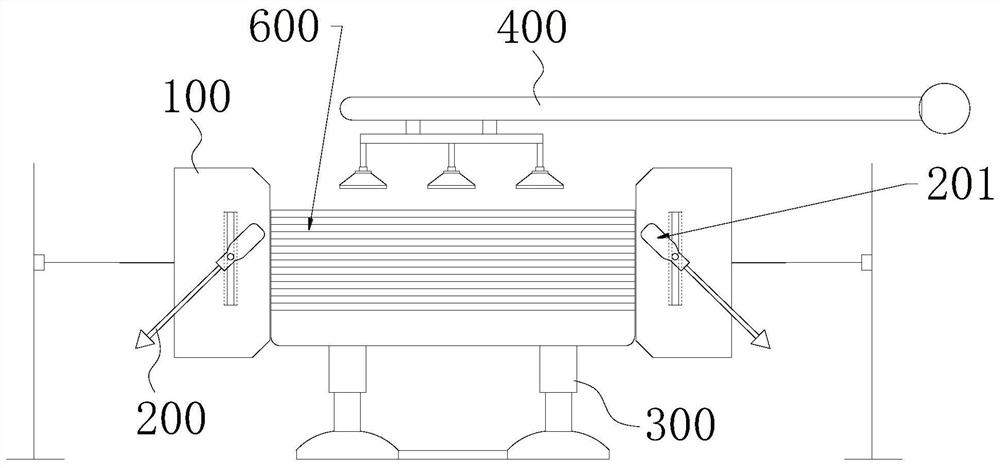

[0044] Such as Figure 1~3 As shown, a stacked board separation device includes a board stacking area 500 for stacking boards, and the board stacking area 500 is equipped with an air blowing module 200 and a magnetic assist module. The air blowing module 200 includes an air nozzle 201 connected with an air supply module, and the air blowing direction of the air nozzle 201 faces the sheet material stacking area 500 and deviates upward. The magnetic assist module includes a magnet pair 100, which includes two magnet seats 110, and the two magnet seats 110 are horizontally oppositely arranged on both sides of the sheet material stacking area 500, and the magnetic poles with different names of the two magnet seats 110 The level is right.

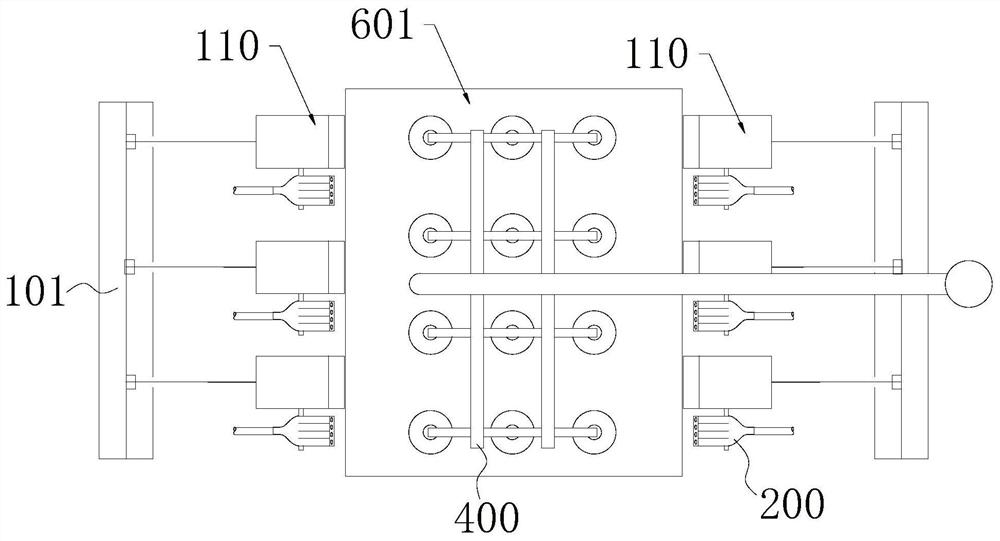

[0045] Such as image 3 , the magnetic assist module includes at least two groups of magnet pairs 100, the magnet pairs 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com