Impulse method solid propellant burning rate test original experiment data validity determination method

A technology of solid propellants and experimental data, applied to jet propulsion devices, rocket engine devices, machines/engines, etc., to achieve the effect of ensuring consistency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0041] The method of the invention is used to analyze and judge the test data of different solid propellants, and select the solid propellant with excellent performance.

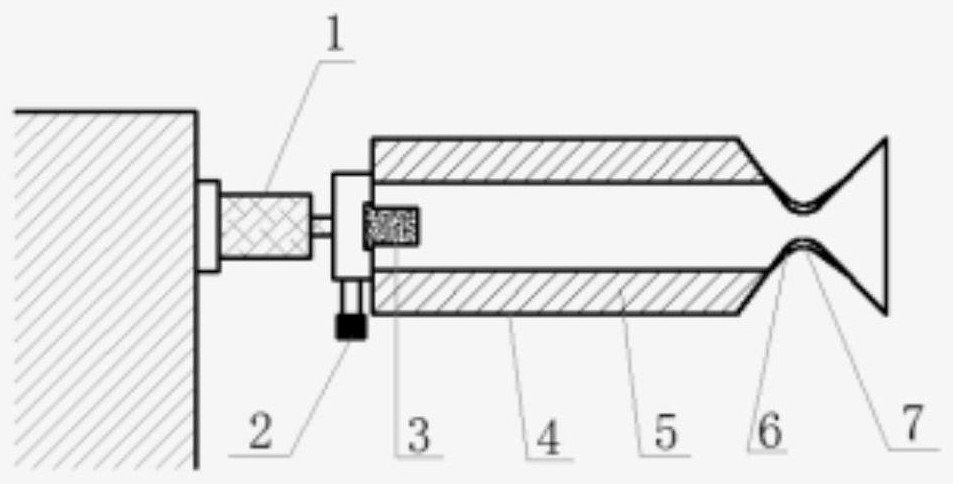

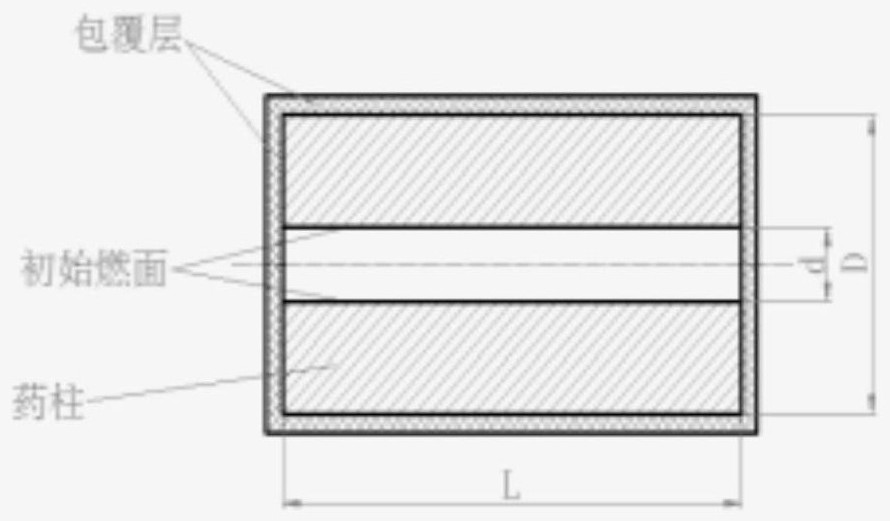

[0042] 1. Measure the shape of the solid propellant to be tested. Since the shape of the propellant used is a tubular grain, it is necessary to record the inner and outer diameters, length, and diameter of the nozzle, as shown in Table 1, which are the size parameters of different propellants.

[0043] Table 1 Size parameters of triple-engine double-base propellant

[0044]

[0045] 2. Cover the outer surface and end surface of the solid propellant grain to be tested according to the requirements, leaving only the inner surface as the initial burning surface.

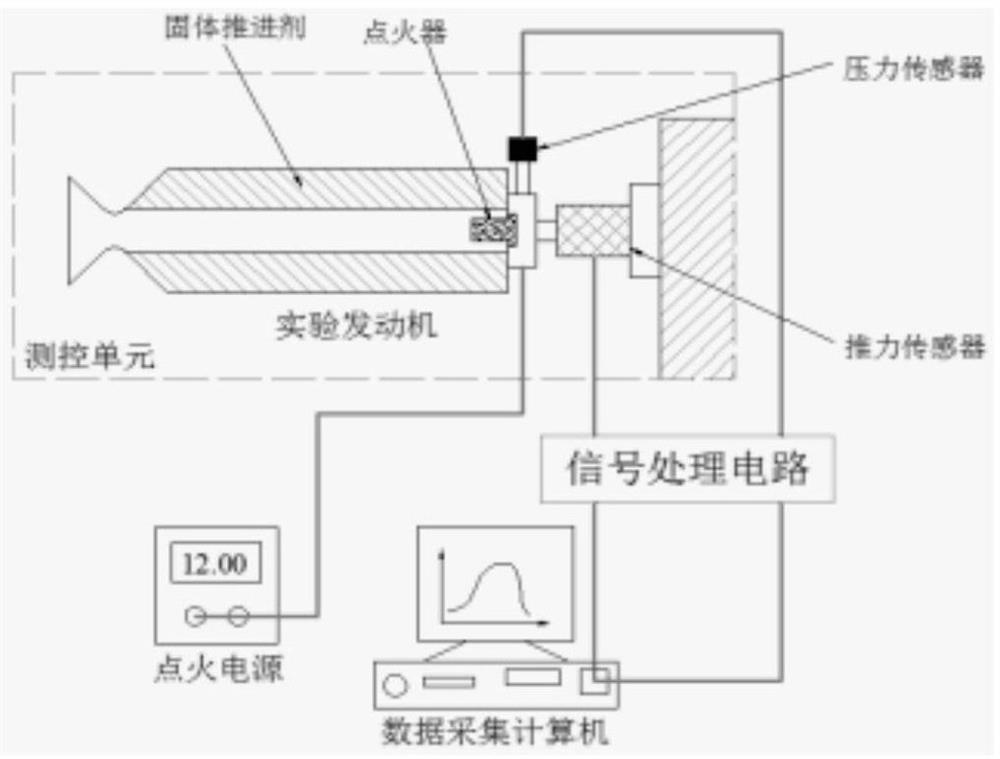

[0046] 3. Freely fill the solid propellant coated as required in the combustion chamber of the rocket engine. Connect the ignition circuit and confirm that the circuit connection is correct, start the ignition button, and observe the real-time cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thrust | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com