Direct-view type method and device for generating any column vector polarized light based on vortex half-wave plate

A half-wave plate and column vector technology, applied in the field of spatial polarization beam shaping, can solve the problems of inability to withstand high-energy laser beams, low SLM area utilization, and no cost-effectiveness, and achieve high energy utilization and conversion efficiency. The effect of simple structure, easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The specific embodiment of the present invention is given in conjunction with the accompanying drawings, and the technical solution of the present invention is described in detail.

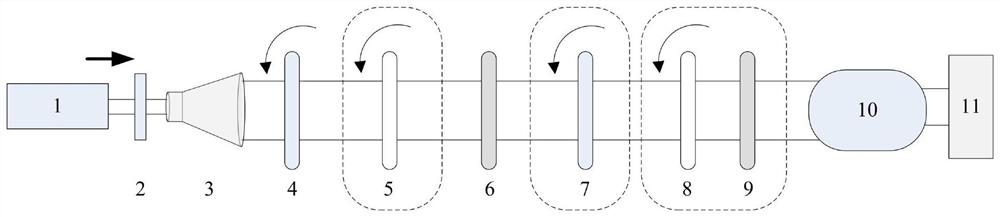

[0070] Such as figure 1 As shown, the beam generation system includes a laser 1, a horizontal polarizer 2, a beam expander 3, a first λ / 2 wave plate 4, a first λ / 4 wave plate 5, a first vortex half-wave plate 6, a second A λ / 2 wave plate 7 , a second λ / 4 wave plate 8 , a second vortex half-wave plate 9 and a beam expander 10 . figure 1 The components in the dotted line box are not placed in the system first, and then selected to be placed and taken out according to the needs of generating light beams. The laser light generated by the laser 1 is guaranteed to become horizontal linearly polarized light after passing through the horizontal polarizer 2, and then through the beam expander 3 to realize beam amplification, and then the polarization direction of the linearly polarized light is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com