Driving certificate manufacturing device and method

A driving license and equipment technology, applied in printing, instruments, cards for carrying information, etc., can solve the problems of high failure rate, complex structure, complex debugging, etc., and achieve the effect of high degree of automation, simple operation, and high certificate production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

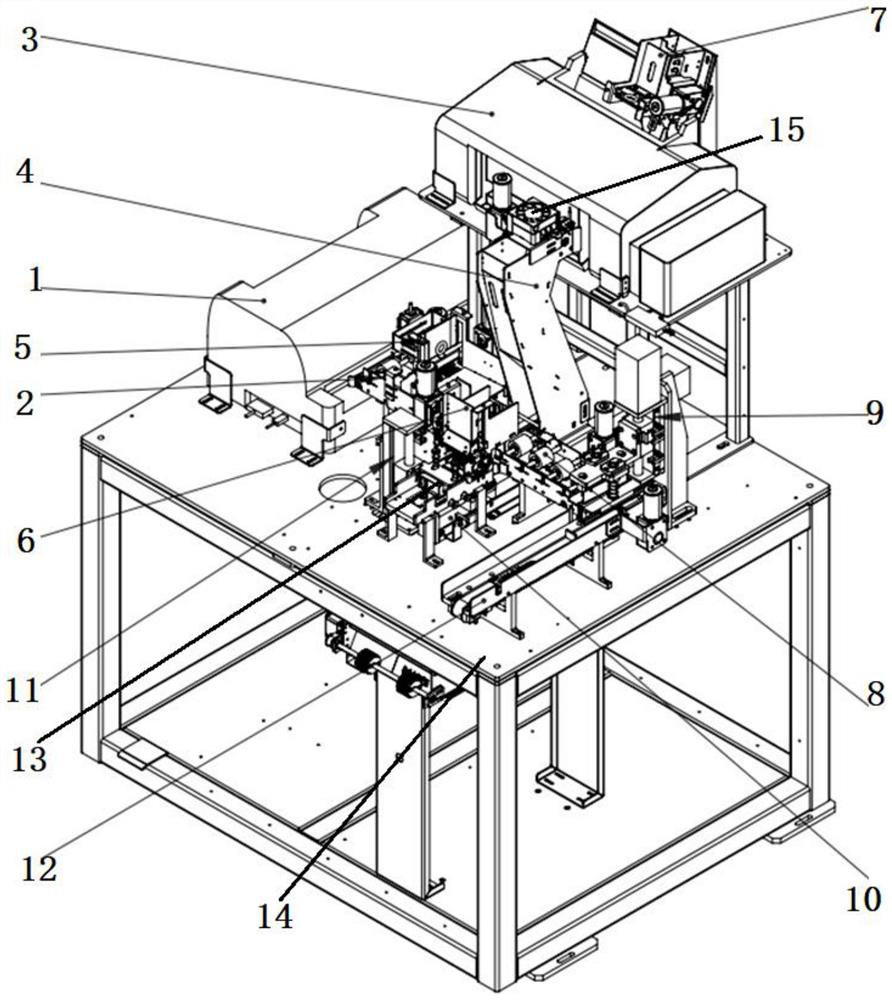

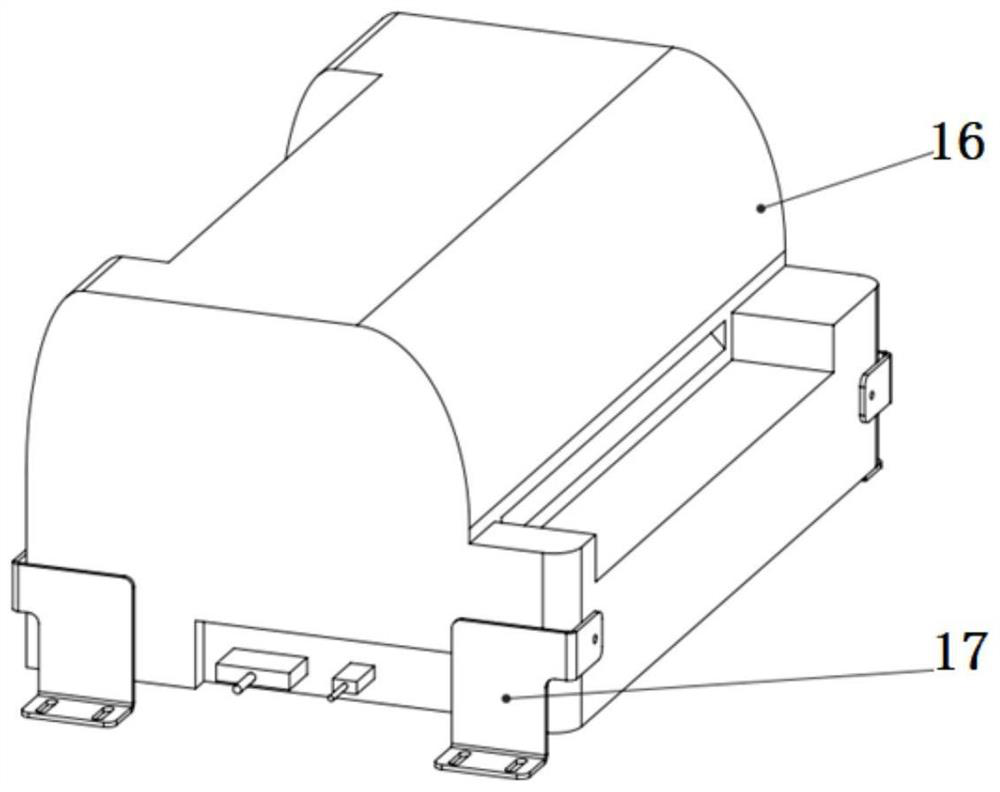

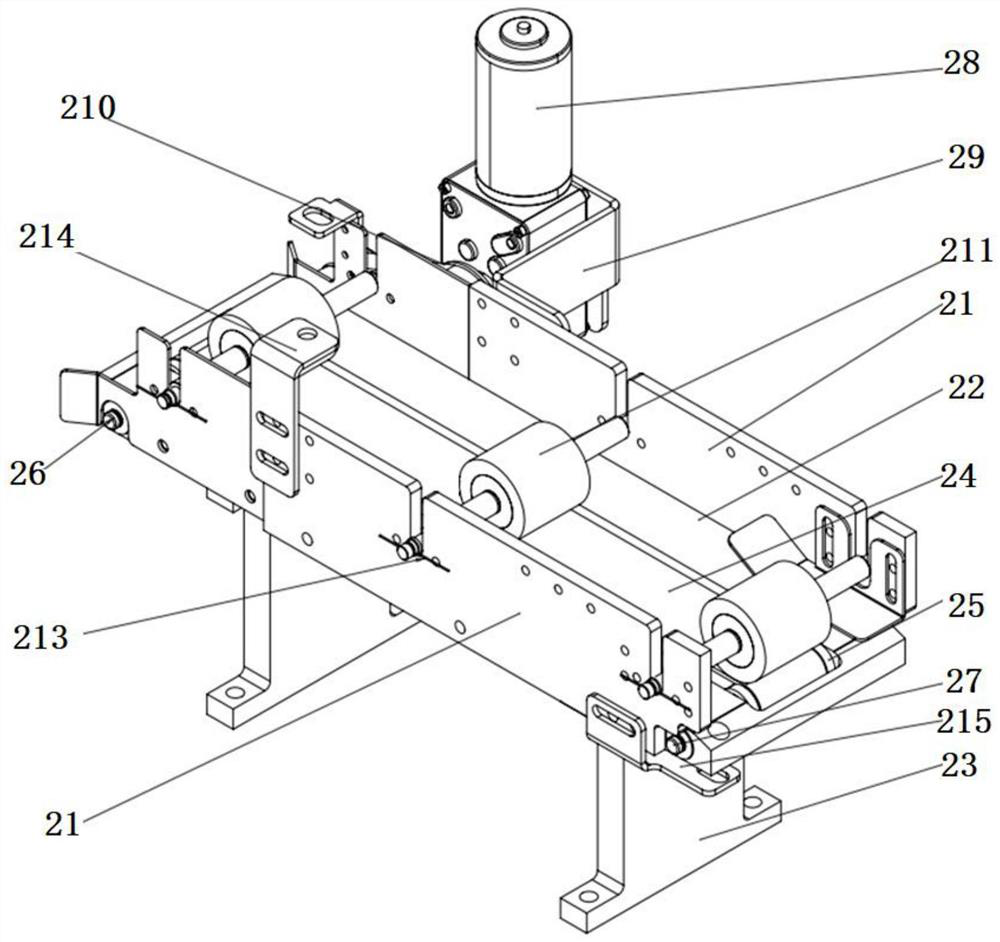

[0054] Refer Figure 1-13 In one, a driving certificate device includes an information printing module 1, a document transport channel 2, a photo printing module 3, a photo flip passage 4, a card cartridge 5, a film cartridge 6, a phase paper cartridge 7, a crop transmission channel 8, cutter assembly 9, principal and photo push module 10, the film absorbing module 11, copy transfer passage 12, the plastic machine 13, chassis 14, and fan 15;

[0055] The chassis 14 is a substrate of the entire device, and the phase paper cartridge 7 is mounted at the inlet of the photo printing module 3, and the fan 15 is mounted on the upper end of the photo flip passage 4, and the other structure is mounted on the chassis 14;

[0056] The information printing module 1 and the photo print module 3 are disposed at the front end of the chassis 14, a fold line-shaped distribution, a cutter assembly 9, and a copy passage 12 are disposed at the rear end of the chassis 14; the card cartridge 5 is dispos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com