Transposer

A technology of transposition device and gear plate, which is applied in the direction of surface tension analysis, etc., can solve the problems of increased measurement cumbersomeness, waste of measurement time, and pollution of hanging pieces, so as to save measurement time, avoid the possibility of collision damage, and manufacture low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

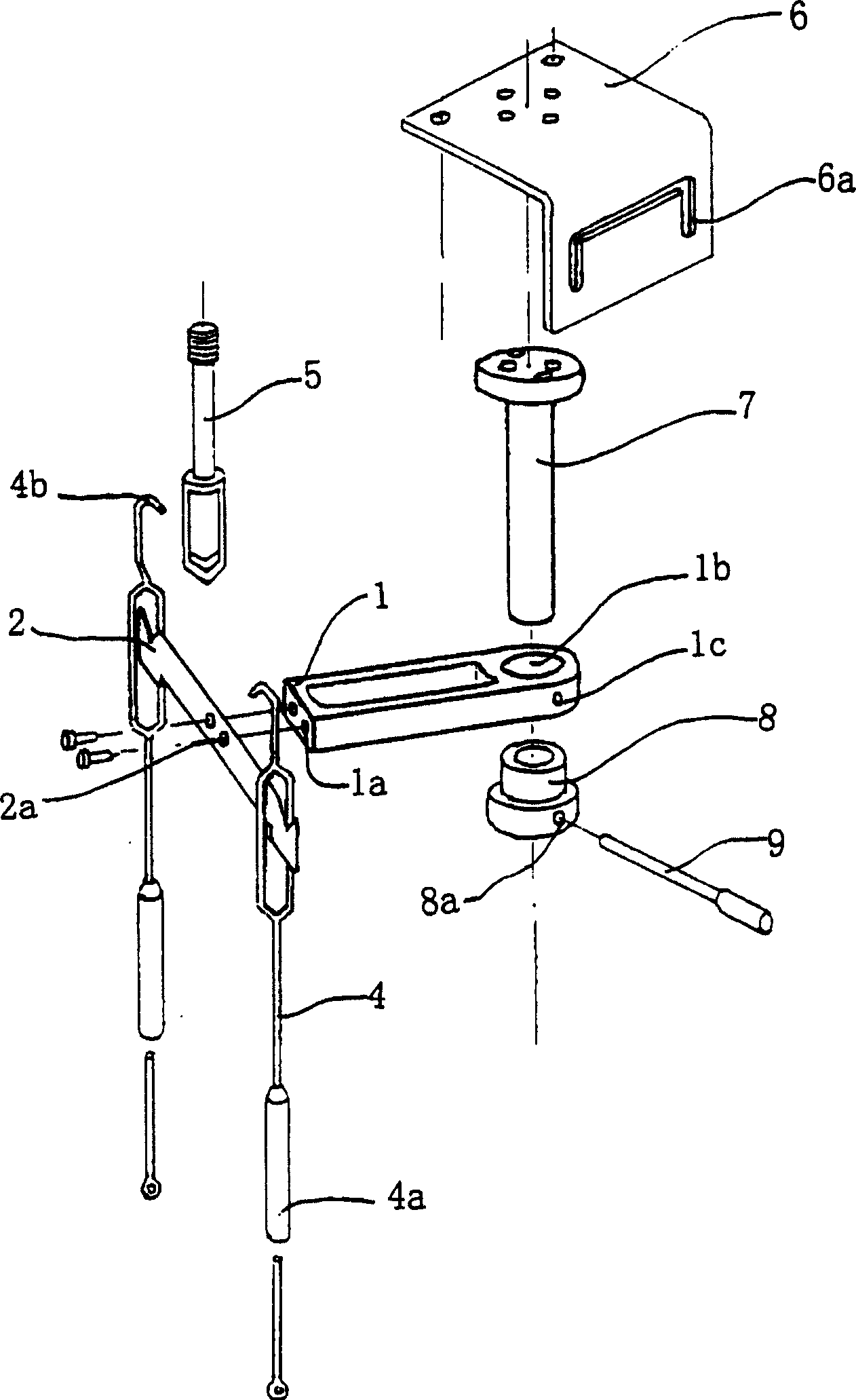

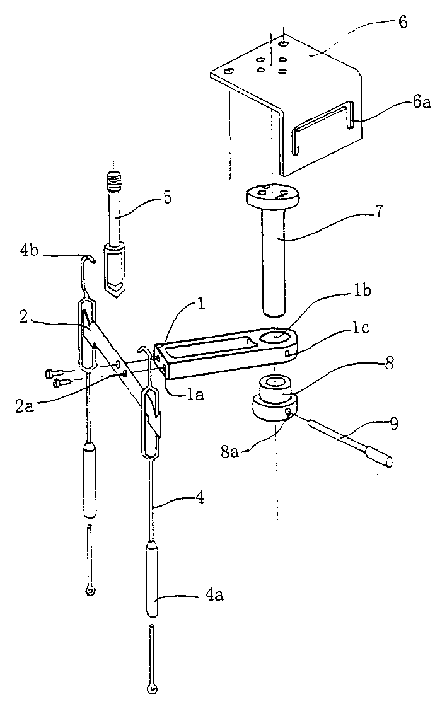

[0009] Such as figure 1 As shown, in the transposition device of the present invention, one end of the cantilever 1 is provided with a connection hole 1 a on the side wall, and the other end is provided with a vertical through hole 1 b and a connection hole 1 c is provided on its side wall. The side wall of the boom bracket 2 is provided with a connecting hole 2a, and the boom 1 and the boom bracket 2 are connected together by connecting elements such as bolts through the connecting holes 1a and 2a thereon. Suspenders 4 are respectively hung on the cutting edges at the two ends of the suspender bracket 2, and a length adjusting rod 4a for adjusting the length of the suspenders can be arranged on the suspenders 4. A hanger (not shown) for measurement is hung on the lower end of the length adjustment rod 4a. The suspension ring 5 connected with the sensor (not shown in the figure) contacts the upper end 4b of the suspension rod 4 during measurement, so as to transmit the measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com