Medium heater of gas dispersion system

A medium heater and gas dispersion technology, which is applied to tobacco and other directions, can solve the problems of high cost and complicated process, and achieve the effects of low cost, simple processing technology and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

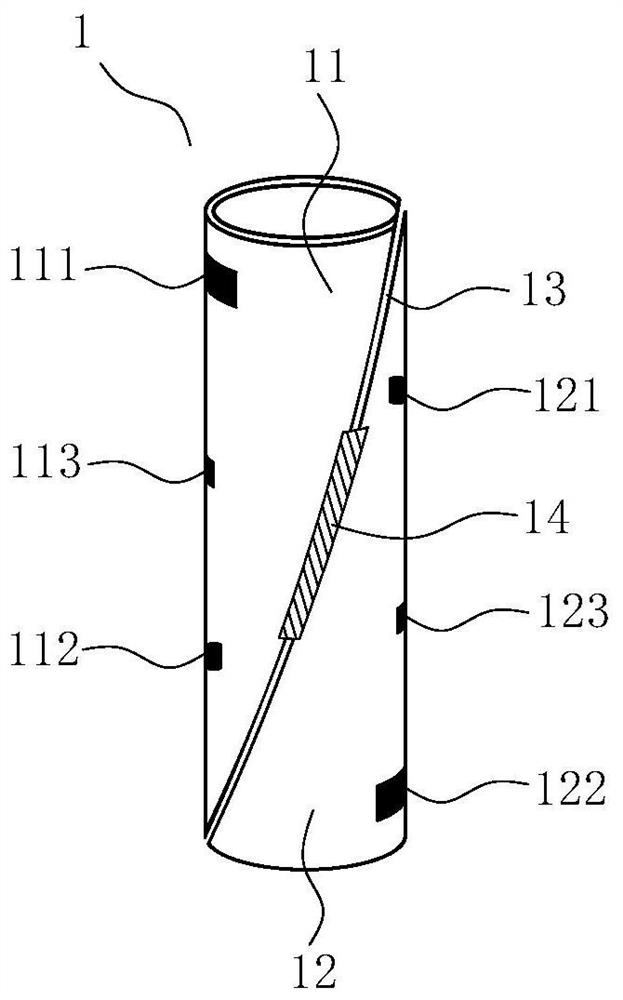

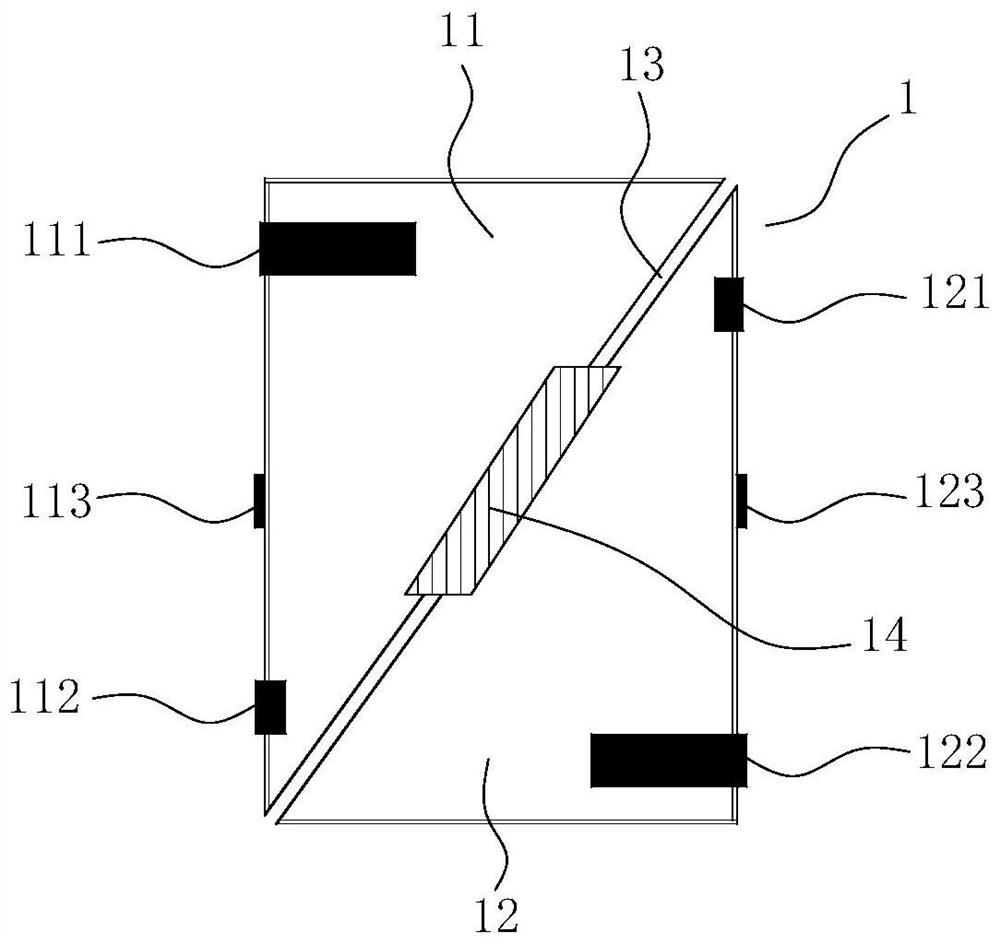

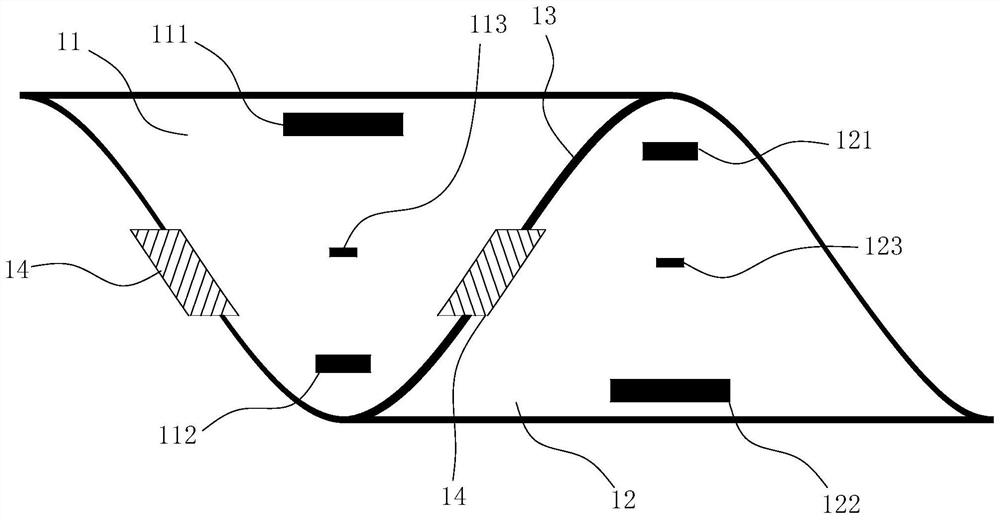

[0028] see figure 1 , the heater in the figure is a specific embodiment of the present invention, which is used for low-temperature smoking articles, and heats the smoking medium to generate a gas dispersion system that can be smoked.

[0029] The body of the heater in the figure is a heating tube 1, and the heating tube 1 is a tube body structure with two open ends, one end of which is used to insert a smoking medium into the inner cavity of the tube, including but not limited to cigarettes or cartridges, heating tubes. The tube body of 1 can be made into a conductor resistance that bakes and heats the inserted smoking medium, that is, a semiconductor, and its interior is relatively uniformly mixed with polycrystalline materials. The inserted smoking medium is thereby heated and released to form a gaseous dispersion. In this embodiment, the tube body is divided into a first heating part 11 and a second heating part 12 which can generate heat independently by the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com