Anti-skid shoe sole for women's shoes and preparation process of anti-skid shoe sole

A preparation process and technology for women's shoes, which are applied to soles, footwear, footwear, etc., can solve problems such as easy slippage, and achieve the effects of improving anti-skid performance, increasing contact area, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

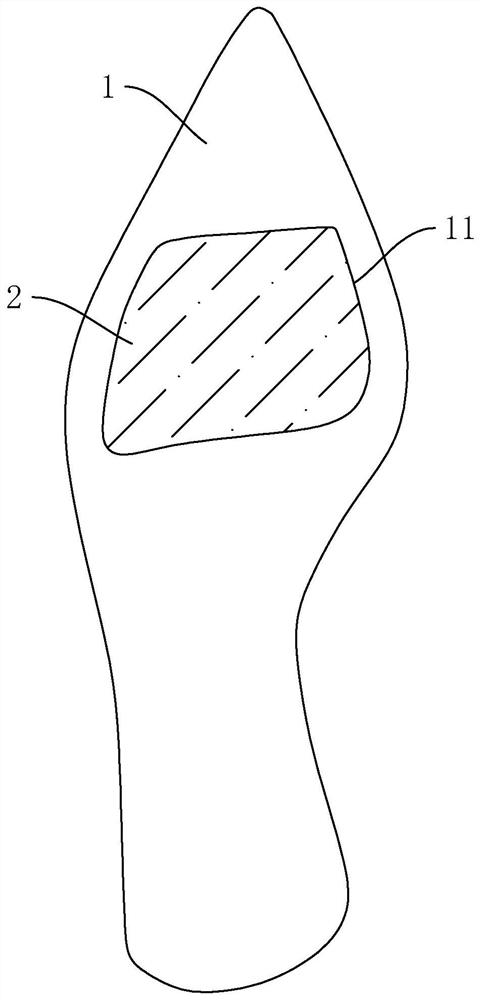

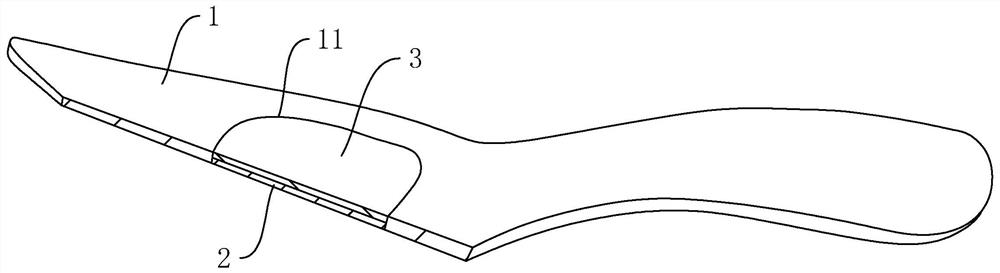

[0046] see figure 1, the application discloses a non-slip women's shoe sole, including a sole body 1, a through hole 11 is opened on the outer side wall of the sole body 1, and the through hole 11 is located in the front half of the sole body 1. An anti-slip block 2 is fixed in the through hole 11 , and the anti-slip block 2 is arranged in close contact with the inner wall of the through hole 11 .

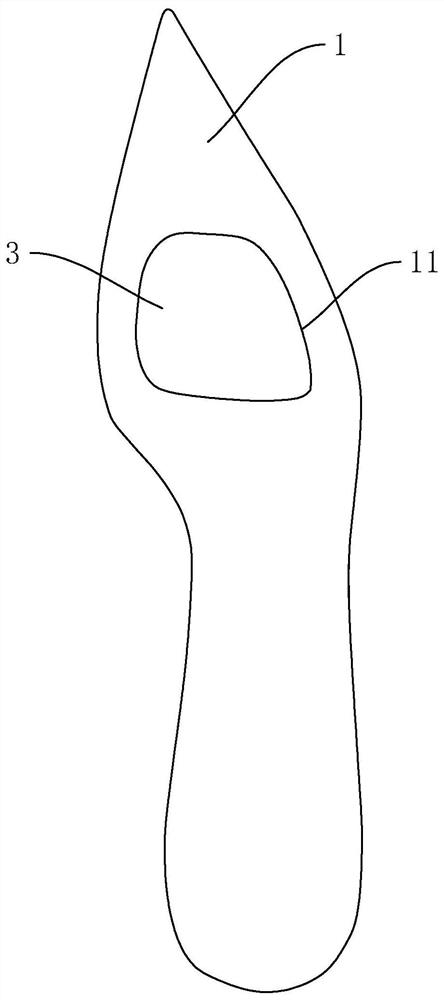

[0047] see figure 2 and image 3 A flexible block 3 is also fixed in the through hole 11, and the flexible block 3 is located on the side of the anti-slip block 2 close to the sole of the foot and is located in the through hole 11. The end surface of the anti-slip block 2 away from the flexible block 3 is processed with anti-slip lines.

[0048] The anti-skid block 2 includes the following raw materials: PVC; zinc salicylate; ethanol; 30wt% potassium hydroxide solution; stabilizer phosphite; Pd, and its preparation process includes the following steps:

[0049] S1. Preparation...

Embodiment 2

[0054] The present application discloses a non-slip women's shoe sole, which includes a sole body 1 , a through hole 11 is opened on the outer side wall of the sole body 1 , and the through hole 11 is located at the front half of the sole body 1 . An anti-slip block 2 is fixed in the through hole 11 , and the anti-slip block 2 is arranged in close contact with the inner wall of the through hole 11 . A flexible block 3 is also fixed in the through hole 11 , and the flexible block 3 is located on the side of the anti-skid block 2 close to the sole of the foot and in the through hole 11 . The end surface of the anti-slip block 2 away from the flexible block 3 is processed with anti-slip lines.

[0055] The anti-skid block 2 includes the following raw materials: PVC; zinc salicylate; ethanol; 30wt% potassium hydroxide solution; stabilizer phosphite; Pd, and its preparation process includes the following steps:

[0056] S1. Preparation of mixture; Stir and mix PVC, zinc salicylate...

Embodiment 3

[0061] The present application discloses a non-slip women's shoe sole, which includes a sole body 1 , a through hole 11 is opened on the outer side wall of the sole body 1 , and the through hole 11 is located at the front half of the sole body 1 . An anti-slip block 2 is fixed in the through hole 11 , and the anti-slip block 2 is arranged in close contact with the inner wall of the through hole 11 . A flexible block 3 is also fixed in the through hole 11 , and the flexible block 3 is located on the side of the anti-skid block 2 close to the sole of the foot and in the through hole 11 . The end surface of the anti-slip block 2 away from the flexible block 3 is processed with anti-slip lines.

[0062] The anti-skid block 2 includes the following raw materials: PVC; zinc salicylate; ethanol; 30wt% potassium hydroxide solution; stabilizer phosphite; Pd, and its preparation process includes the following steps:

[0063] S1. Preparation of mixture; Stir and mix PVC, zinc salicylate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap