Near-net composite forming method for large wall thickness sudden change ring part

A compound forming and ring technology, applied in metal processing equipment, metal rolling, etc., can solve the problems of destroying the distribution of metal streamlines, weakening the mechanical properties of rings, and low material utilization, so as to improve the distribution of residual stress, Improve the material utilization rate and the integrity of the metal streamline distribution, and improve the mechanical properties of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

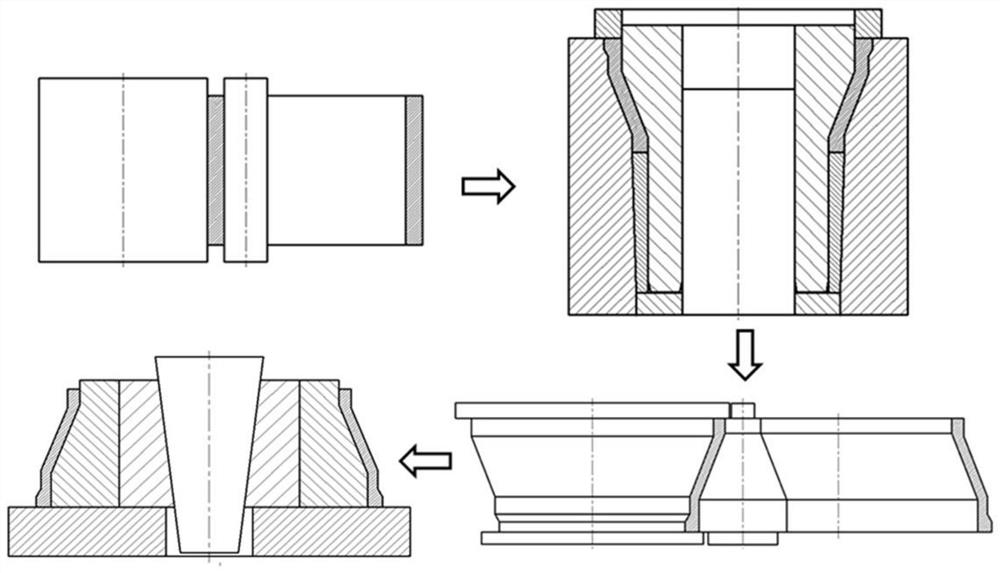

Method used

Image

Examples

Embodiment

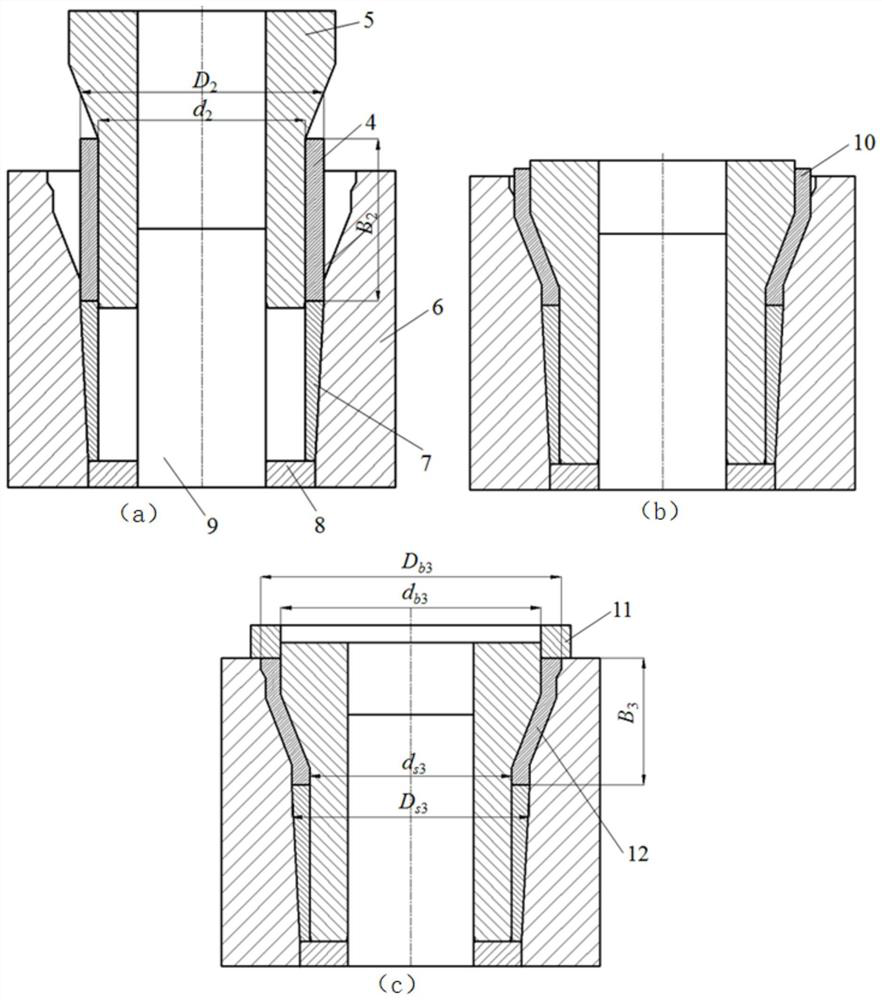

[0039] The outer diameter D of the large end of the required target ring 20 b5 =1116mm, inner diameter d b5 =1000mm, small end outer diameter D s5 =870mm, inner diameter d s5 =760mm, overall height B 5 =500mm, material GH4169, weight 588.5kg.

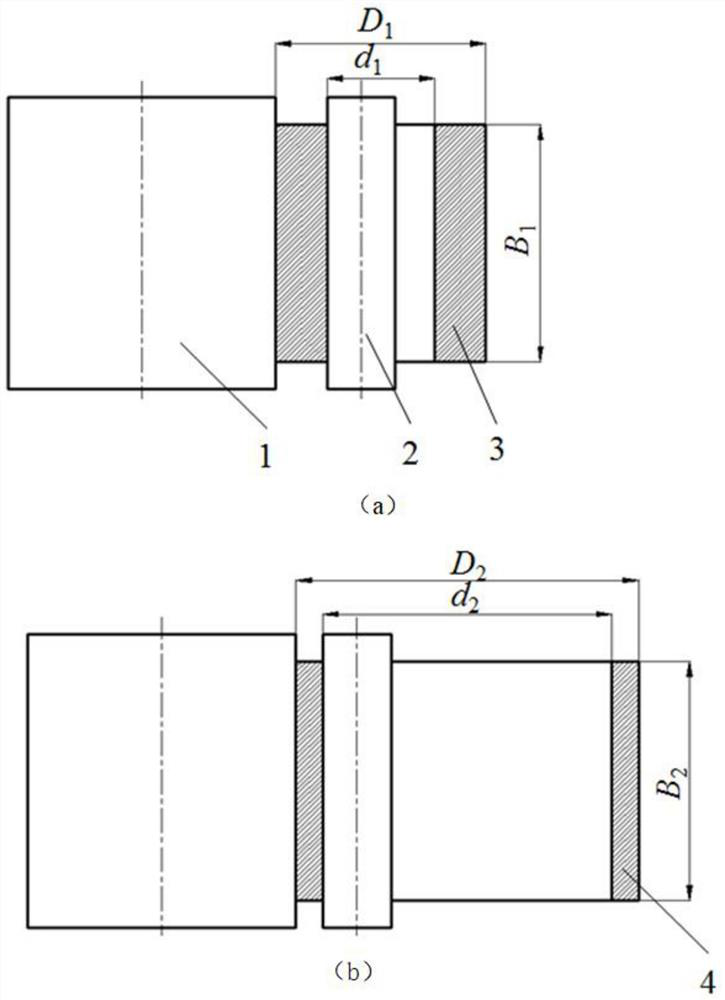

[0040] In step S1: forging and punching to obtain a small-diameter rectangular cross-section ring blank 3, the outer diameter of which is D 1 =506mm, inner diameter d 1 =280mm, height B 1 =513mm, put it into a heating furnace to heat and keep it warm for a period of time, the heating temperature is controlled within the range of 1010-1040°C, and the heating time is 3-6h; 1 main roll and core roll 2 are preheated to 200-300°C, and the clamping ring The operator of the blank covers a layer of insulation cotton, quickly takes out the ring blank and puts it on the hot rolling ring machine for rolling. During the rolling process, a relatively high feed speed is adopted, and the rolling is stopped when the outer diameter grows to 712mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com