Gas turbine blower impeller isothermy die forging method

A gas turbine and isothermal die forging technology, applied in the field of forging, can solve the problems of large centrifugal force, fracture of the impeller, and the inability to meet the requirements of strong and toughness of the impeller, and achieve the effects of reducing the contact friction coefficient, improving the demoulding force of forgings, and increasing the elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, first determine the isothermal temperature of the 2A50 aluminum alloy mold and the impeller blank, and use the 2A50 forged aluminum alloy material to make a standard sample, and simulate the actual isothermal deformation rate on the 1-5-2 high-temperature material testing machine for a high-temperature tensile test. The plasticity and deformation resistance diagram of the alloy, so as to find the optimal isothermal temperature of the mold and impeller blank: 480°C; creep rate: 5×3.4×10 -4 the s -1 , Isothermal deformation on YA32-500 5000kN hydraulic press. The outer diameter of the blank that will be turned on the lathe 43 is heated to 200°C in a KO-11 box-type resistance furnace, taken out, sprayed with the first lubricant, then placed in the furnace and heated to 480°C, and kept for 80 minutes.

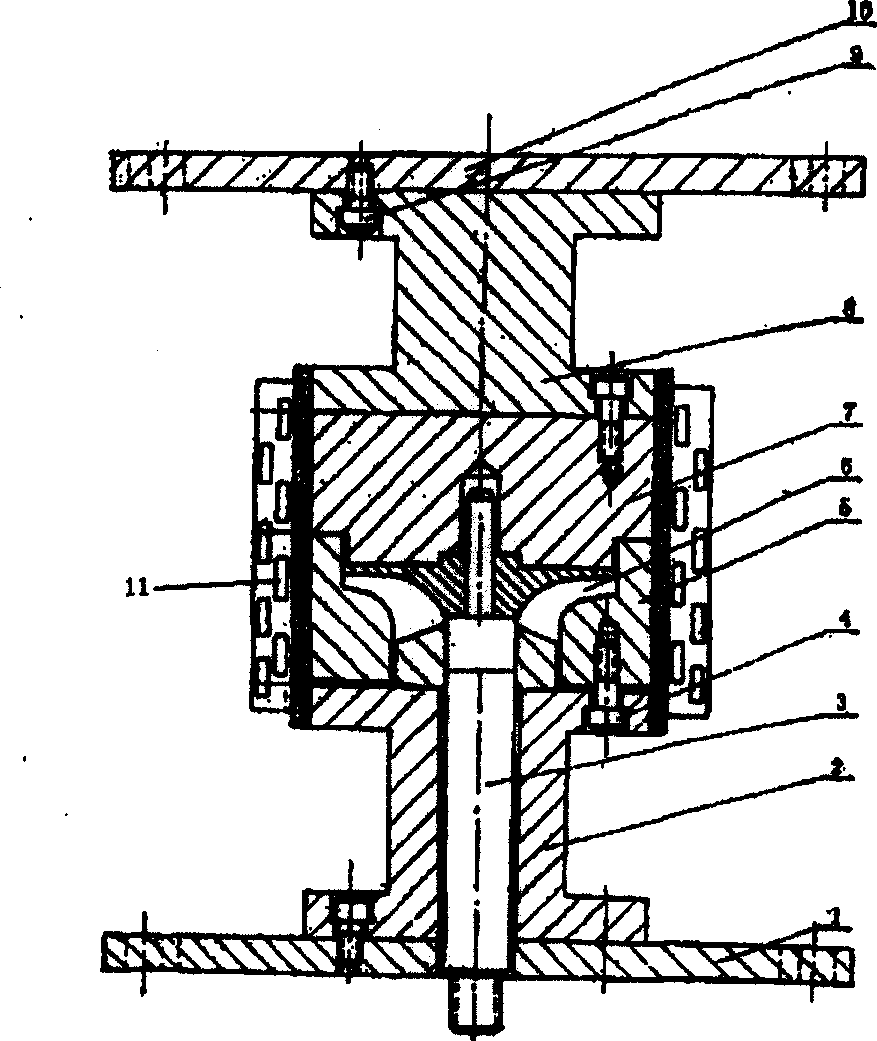

[0028] Then design the mold for isothermal die forging, the mold structure is as follows figure 2 shown. The die 5 is fixed on the lower backing ...

Embodiment 2

[0032] During implementation, use the existing YA32-500 5000kN hydraulic press. The outer diameter of the impeller blank that will be turned on the lathe 43 Heated to 210°C in a KO-11 box-type resistance furnace, took it out, sprayed the first lubricant, then placed it in the furnace and heated it to 490°C, and kept it warm for 80 minutes; heated the mold to 470°C with medium frequency induction, Spray the first lubricant, put the heated impeller blank in the mold, and keep the temperature for 30 seconds, and then the press starts to press down. After about 1 minute, when there is 9mm left, the press slowly presses down for about 4.5 minutes. until the mold is fully closed. The movable beam of the press goes up, the mold is opened, the water-cooled impeller forging (the impeller forging is easily deformed due to heat ejection), and the lower ejector rod 3 ejects the impeller forging.

[0033] In this embodiment, compared with the common die forging, the strength is increa...

Embodiment 3

[0035] During implementation, a YA32-630 6300kN hydraulic press is used. The outer diameter of the impeller blank that will be turned on the lathe Heat it to 190°C in a KO-11 box-type resistance furnace, take it out, spray the first lubricant, put it in the furnace and heat it to 470°C, and keep it warm for 100 minutes; heat the mold to 490°C with medium frequency induction, and spray The first kind of lubricant, put the heated impeller blank in the mold, and then keep the temperature for 20 seconds, and the press starts to press down. After 50 seconds, when there is 10mm left, the press slowly presses down for about 4 minutes until the mold fully closed. The movable beam of the press goes up, the mold is opened, the impeller forging is water-cooled (the impeller forging is easily deformed due to heat ejection), and the lower ejector pin ejects the impeller forging. Because the press is larger than the tonnage of Example 2, the blank temperature can be reduced by 10°C.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com