Sprue basin and manufacturing and using method

A sprue basin and sprue technology, which is applied in the direction of manufacturing tools, casting molding equipment, safety devices, etc., can solve the problems of cold shut, slag inclusion, etc., and achieve the effect of simple operation method, low manufacturing cost and reducing slag inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to illustrate the technical solution of the present invention more clearly, the present invention will be further described in detail below in conjunction with specific examples. Please note that the embodiments described below are exemplary only for explaining the present invention, and should not be construed as limiting the present invention.

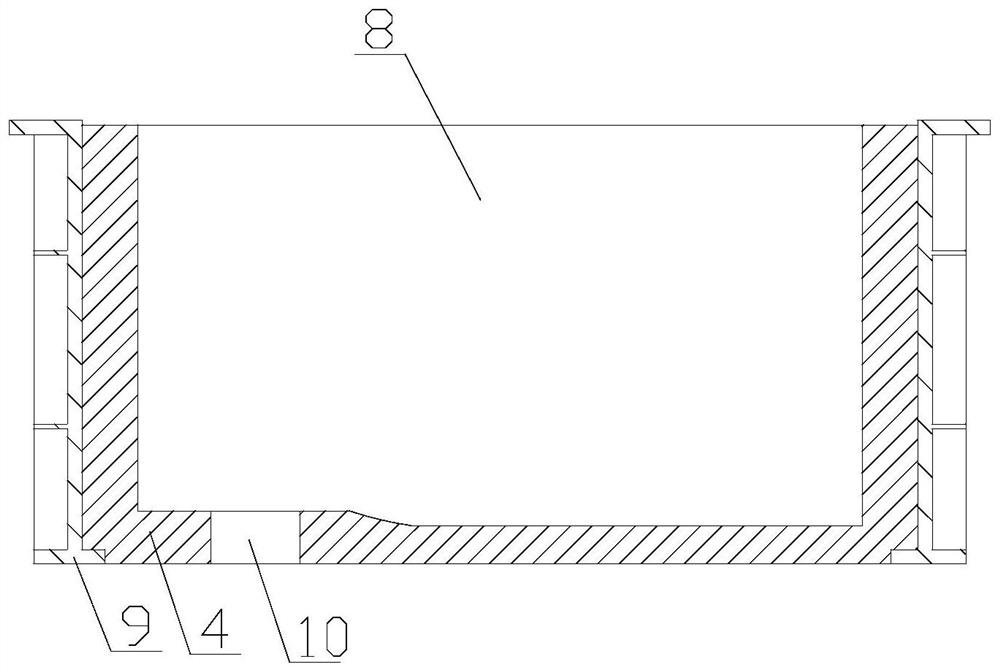

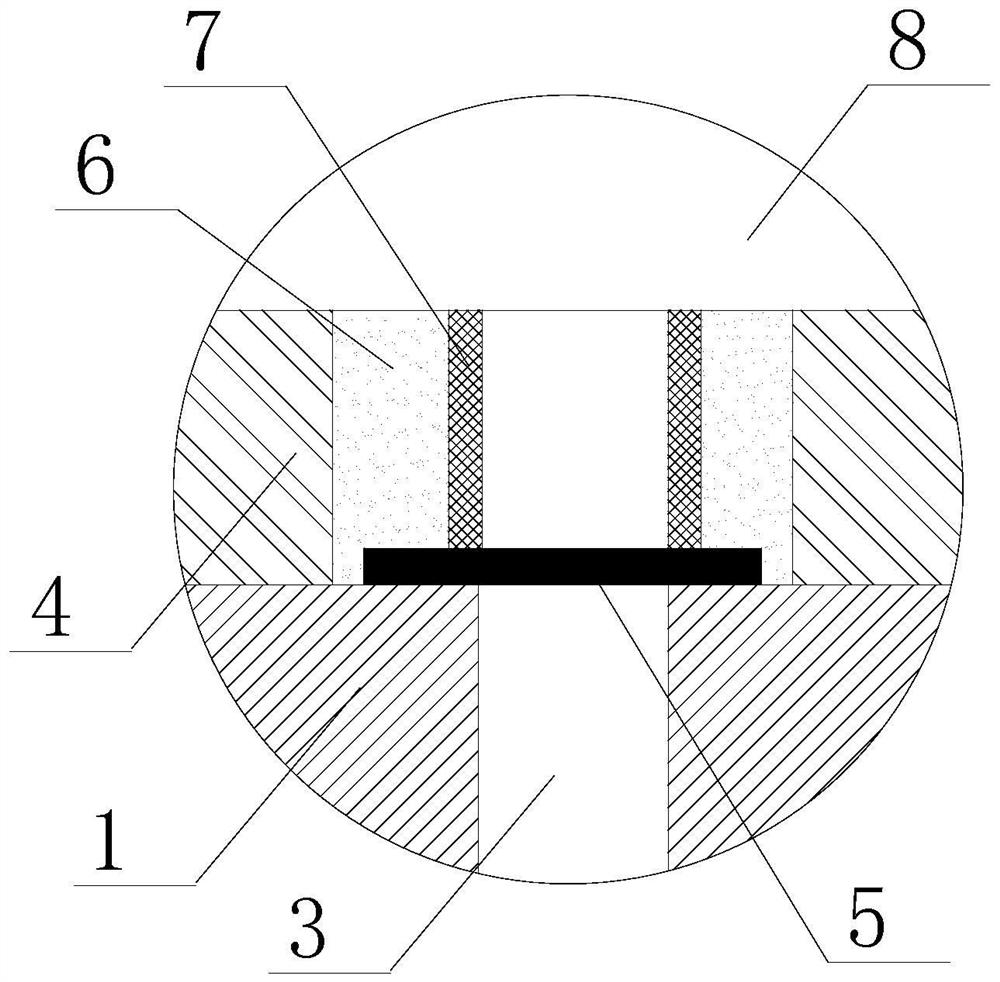

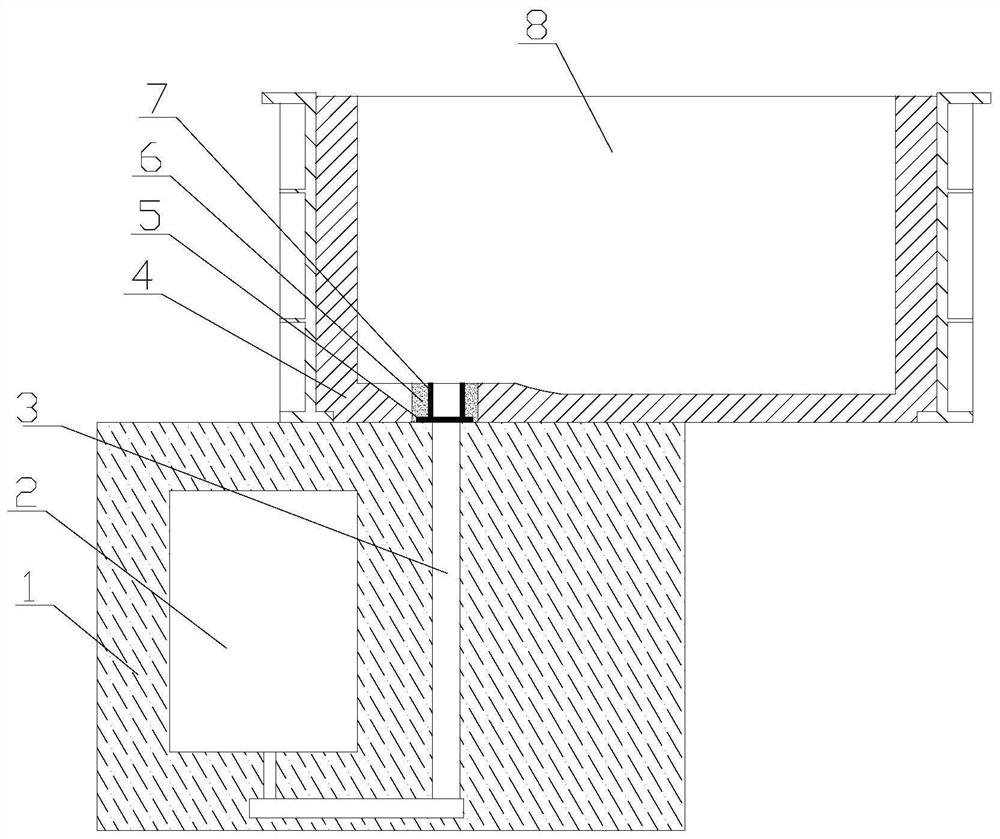

[0021] A sprue basin, such as figure 1 , including sprue basin sand mold 4 and sprue basin sand box 9, sprue basin sand box 9 is arranged on the outside of sprue basin sand mold 4 along the circumference, sprue basin sand box 9 can be welded or cast by steel plate, pouring The sprue basin sand box 9 is provided with a hanger, thereby facilitating the transfer of the sprue basin. The gate basin sand mold 4 is arranged inside the gate basin sand box 9, and the gate basin sand mold 4 is a hollow tank body, thereby forming a liquid containing chamber 8. Below the sprue basin sand mold 4, that is, on the side where the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com