An automatic transport system for the recovery and circulation of defective particles and its application

A defective product recycling and automatic conveying technology, which is applied in the direction of conveyor objects, transportation and packaging, solid separation, etc., can solve the problems of unsolved automatic recycling and conveying of defective products, the inability to mix coarse and fine materials evenly, and uneven product quality levels. , to achieve the effect of improving pass rate and product quality, reducing frictional static electricity, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

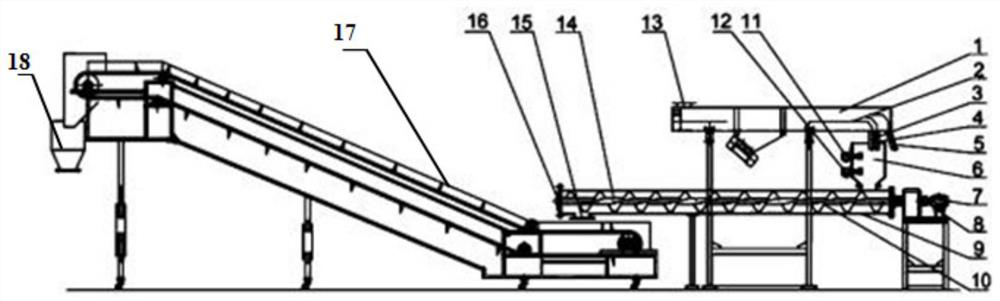

[0038] An on-line plastic granule defective product recycling automatic conveying system, comprising a feeding collection device, a screw conveying device and a lifting conveying device, the main body of the feeding collecting device is a vibrating screen 1, preferably designed as a three-layer linear vibrating screen, specifically a Vibrating structure; the upper part of one end of the vibrating screen 1 is fixed with a feed port 13, and a screen 2 is directly fixed under the feed port 13. The screen 2 is provided with apertures of different sizes, and the bottom end of the screen is connected and fixed with a defective coarse Material outlet 3, defective fine material outlet 4 and qualified product outlet 5, the qualified product outlet is connected to the finished product warehouse; the aperture of the defective coarse material outlet is 6-8cm, and the aperture of the defective fine material outlet For less than 2cm, the aperture of the qualified product discharge port is 2-...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that, 2 minutes before the opening of the screw conveying device, the spray head starts to work, and the atomized particle diameter of the spray head is 10 microns; the volume of the defective plastic particles and the antistatic agent The ratio is 100:0.4;

[0046] The spray head is 100mm from the upper edge of the hopper;

[0047] The antistatic agent comprises the following components in parts by weight: 0.1 part of dawa gum, 3 parts of vegetable oil and 100 parts of water, and the vegetable oil is corn oil.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that, 3 minutes before the opening of the screw conveying device, the spray head starts to work, and the atomized particle diameter of the spray head is 7 microns; the volume of the defective plastic particles and the antistatic agent The ratio is 100:0.3;

[0050] The spray head is 200mm from the upper edge of the hopper;

[0051] The antistatic agent comprises the following components in parts by weight: 0.06 parts of dawa gum, 1.5 parts of vegetable oil and 100 parts of water, and the vegetable oil is corn oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com