Vehicle Exhaust Particulate Collection and Regeneration Device, Method and Vehicle

A particle capture and regeneration device technology, which is applied in the direction of exhaust device, electric control of exhaust treatment device, exhaust treatment, etc., can solve problems such as flameout and engine damage, so as to improve regeneration ability, avoid engine damage, reduce The effect of failure risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

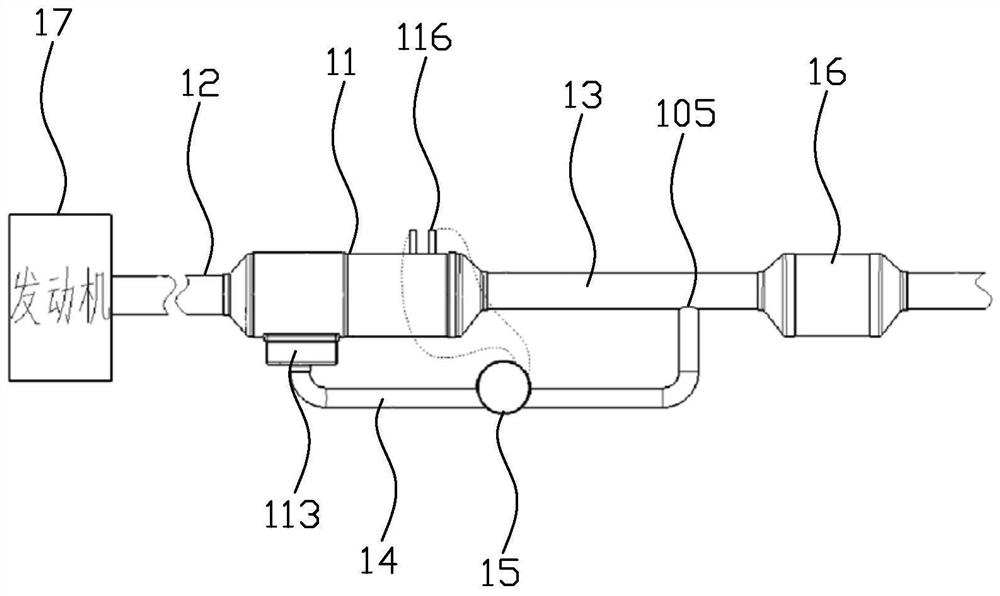

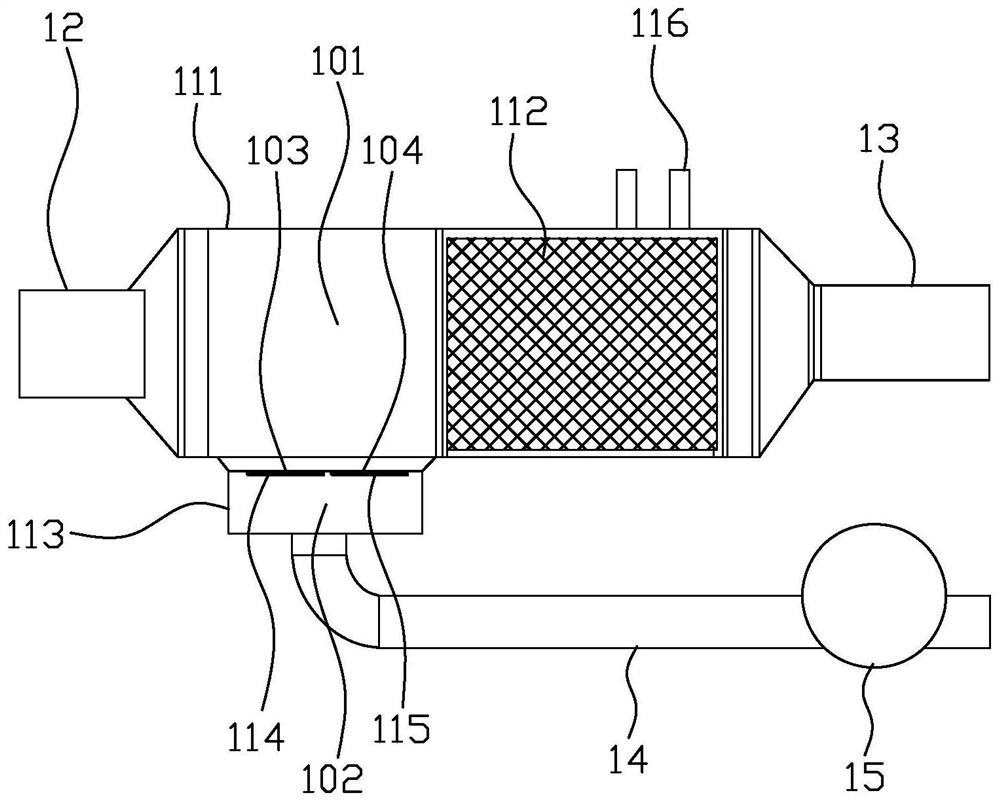

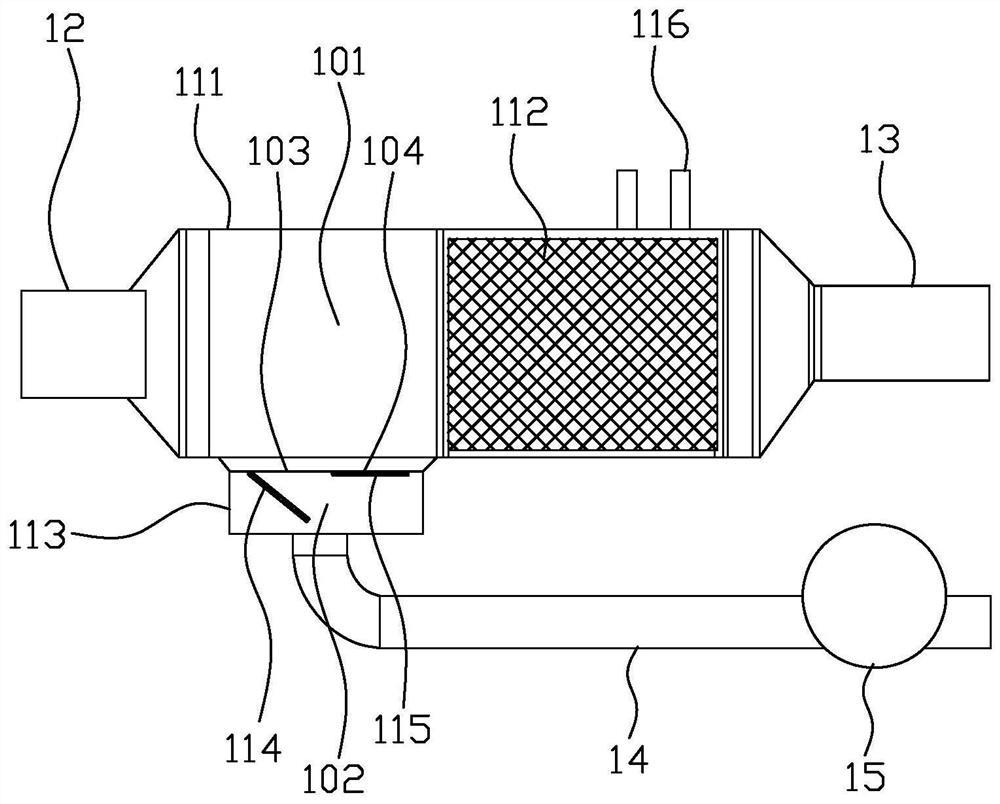

[0024] figure 1 is a schematic diagram of a vehicle exhaust particulate trap regeneration device according to the first embodiment of the present invention, Figure 2 to Figure 5 It is a schematic diagram of the cross-sectional structure of the particle trapping assembly of the present invention in different states, please refer to Figure 1 to Figure 5 The vehicle exhaust particulate trap regeneration device includes a particulate trap assembly 11, an intake pipe 12, a first exhaust pipe 13 and a second exhaust pipe 14, and the particle trap assembly 11 includes a housing 111 and is arranged on the housing The particle trap 112 in 111 has an air intake chamber 101 inside the casing 111, and a valve cover 113 is provided outside the casing 111. The valve cover 113 has an air collection chamber 102 inside, and the casing 111 is provided with an air collection chamber 102 communicates with the first split port 103 and the second split port 104, and the valve cover 113 is provid...

no. 2 example

[0041] The present invention also relates to a method for trapping and regenerating vehicle exhaust particles. The method uses the above-mentioned device for trapping and regenerating vehicle exhaust particles. The method includes:

[0042] When the thrust Fv acting on the first elastic valve 114 and the second elastic valve 115 is less than the first pre-tightening force F1 and the second pre-tightening force F2 of the first elastic valve 114 and the second elastic valve 115, the first elastic valve 114 and the second elastic valve 115 are in a closed state, and the airflow is discharged from the first exhaust pipe 13 after passing through the particle trap 112;

[0043] When the thrust Fv is greater than the first pre-tightening force F1 and / or the second pre-tightening force F2, the first elastic valve 114 and / or the second elastic valve 115 are in an open state, so that the air intake chamber 101 and the air collection chamber 102 are connected , the airflow in the air int...

no. 3 example

[0050] The present invention also relates to a vehicle, including the above-mentioned vehicle exhaust particle collection and regeneration device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com