Fuel cell air humidity adjusting system and control method thereof

An air humidity and fuel cell technology, applied in fuel cells, electrical components, circuits, etc., can solve the problems of narrow humidity adjustment range and poor humidity control accuracy, and achieve the goals of avoiding surge, precise and fast control, and improving response rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following specific examples illustrate the present invention in further detail.

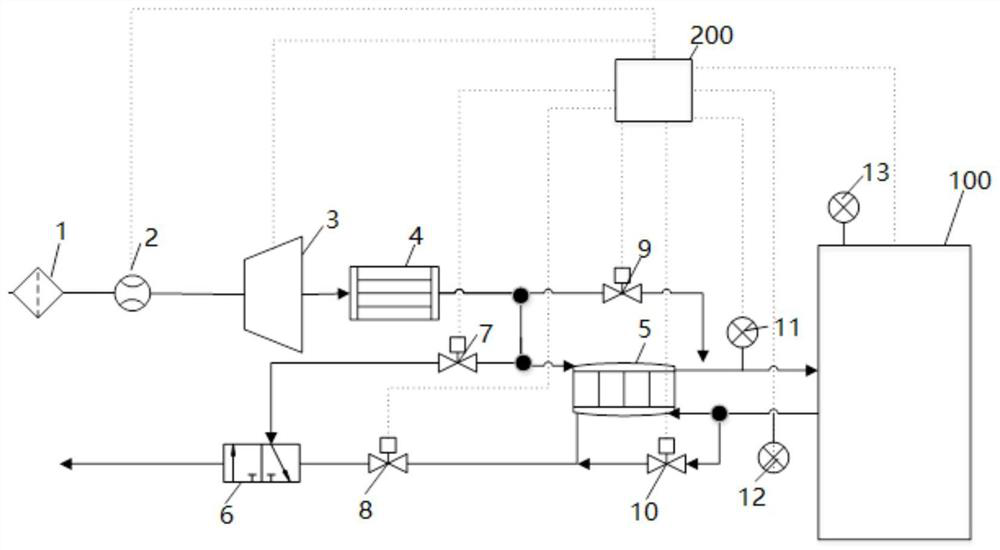

[0035] Such as figure 1 As shown, a fuel cell air humidity conditioning system provided by the present invention includes a stack 100, a controller 200, an air filter 1, a flow meter 2, an air compressor 3, an intercooler 4, a humidifier 5, a mixed row Air filter 6, air filter 1, flow meter 2, air compressor 3, intercooler 4, humidifier 5, the dry air side is sequentially connected to the cathode inlet of the stack 100 along the air intake direction, and the cathode outlet of the stack 100 is along the exhaust The direction connects the wet air side of the humidifier 5 and the mixer 6 in turn. A pressure relief valve 7 for adjusting the inlet pressure of the cathode of the stack 100 is arranged between the intercooler 4 and the mixer 6. The cathode outlet of the stack 100 is connected to the mixer. A back pressure valve 8 for adjusting the outlet pressure of the cathode of the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com