Efficient energy-saving type oil-electric hybrid numerical control bending machine

A bending machine, energy-saving technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of low energy utilization, easy heating of the system, and large energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, and this embodiment does not constitute a limitation to the present invention.

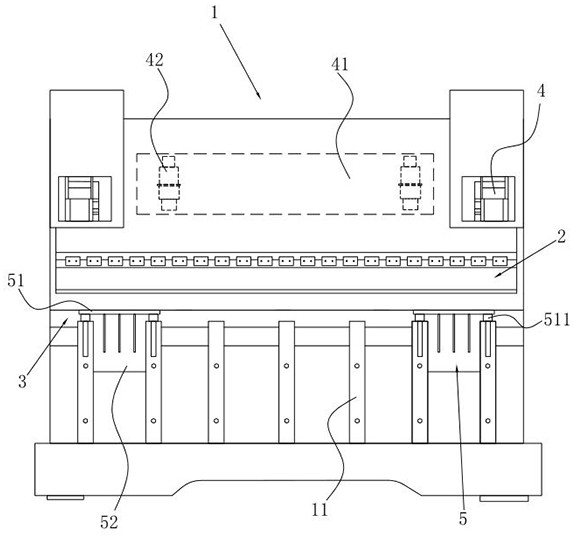

[0026] A high-efficiency and energy-saving oil-electric hybrid CNC bending machine, such as figure 1 As shown, it includes a bending machine body 1, the bending machine body 1 includes an upper mold 2 and a lower mold 3 arranged up and down, the upper mold 2 is detachably connected with a tool for bending, and the lower mold 3 is detachably connected with a There are positioning slots matching the bending tool, and the body is also equipped with lighting and alarm devices. It uses the whole machine finite element software analysis module to calculate the rationality of the strength and structure of the frame, adopts the overall welded structure frame, normalizes and high-frequency vibration to eliminate internal stress, and ensures the long-term rigidit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com