A maintenance method for ink circulation system of ceramic inkjet machine

A technology of ceramic inkjet and circulation system, applied in printing and other directions, can solve the problems that inkjet printers cannot keep continuous printing and the nozzle holes of nozzles are blocked.

Active Publication Date: 2022-03-15

DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The technical problem to be solved by the present invention is to provide a maintenance method for the ink circulation system of a ceramic inkjet machine in view of the above-mentioned defects of the prior art, aiming at solving the problem that once the ceramic tile production line stops in the prior art, the inkjet printer cannot Keep continuous printing, it is easy to cause the problem of nozzle hole clogging

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0087] In terms of mass percentage, the maintenance solvent includes: 93% isooctyl palmitate, 5% isopropyl laurate, and 2% dispersant.

Embodiment 2

[0089] In terms of mass percentage, the maintenance solvent includes: 93% isooctyl stearate, 5% isopropyl laurate, and 2% dispersant.

Embodiment 3

[0091] In terms of mass percentage, the maintenance solvent includes: 93% isooctyl palmitate, 5% isopropyl myristate, and 2% dispersant.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

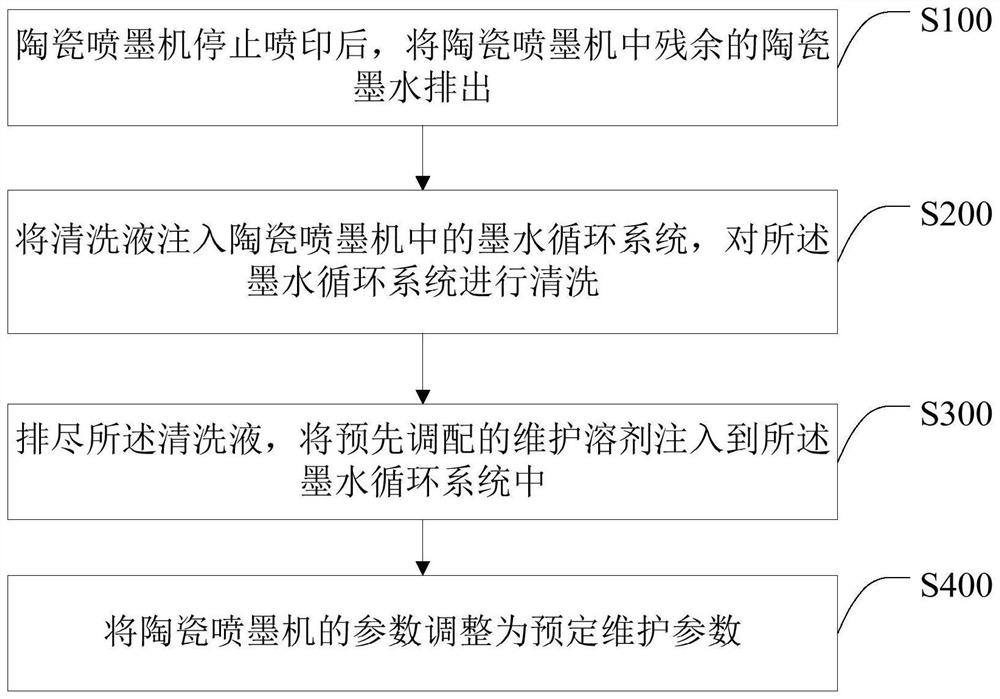

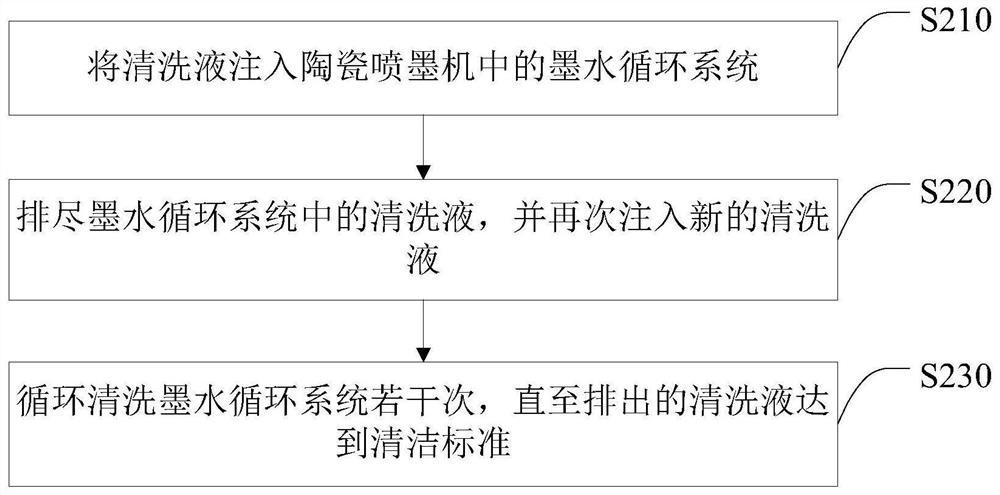

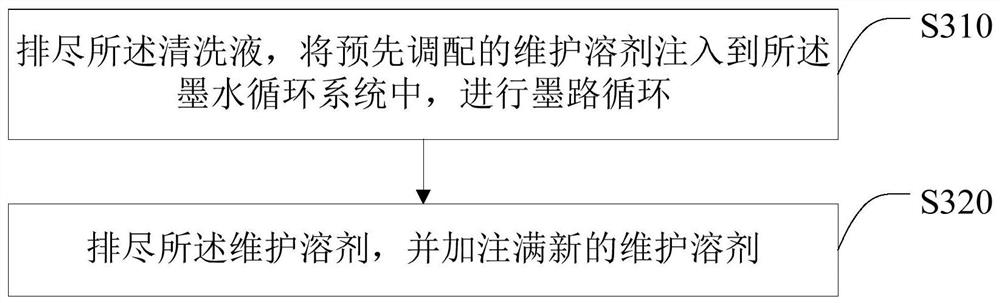

A method for maintaining the ink circulation system of a ceramic inkjet machine provided by the present invention includes: after the ceramic inkjet machine stops printing, discharge the remaining ceramic ink in the ceramic inkjet machine; inject cleaning liquid into the ceramic inkjet machine Clean the ink circulation system of the ink circulation system; drain the cleaning liquid, inject the pre-prepared maintenance solvent into the ink circulation system; adjust the parameters of the ceramic inkjet machine to the predetermined maintenance parameters. The present invention injects a maintenance solvent into the ink circulation system of the ceramic inkjet machine, and adjusts the parameters of the ceramic inkjet machine to predetermined maintenance parameters, so that the ceramic inkjet machine will not bring the risk of failure when it is idle or shut down for a long time, and reduces the risk of failure. Reduce the probability of nozzle clogging and prolong the service life of the ink circulation system of the ceramic inkjet machine.

Description

technical field [0001] The invention relates to the technical field of ceramic inkjet machines, in particular to a method for maintaining the ink circulation system of ceramic inkjet machines. Background technique [0002] The development of architectural ceramics is closely related to the progress of ceramic machinery. It is no exaggeration to say that it is the progress of ceramic machinery that drives the development of the building ceramic tile industry. With the development of architectural ceramic tiles to this day, in addition to the most basic surface ease of cleaning, the most important thing, which is also the most concerned by people, is its surface decoration performance. The strength of the surface decoration performance of ceramic tiles directly determines the sales of ceramic tiles, and even determines the success of product development, which plays a vital role. [0003] From the perspective of the development history of the decoration technology of architec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B41J2/01B41J2/175B41J2/185

CPCB41J2/01B41J2/185B41J2/175

Inventor 盛正强欧志勇曹端旭李艳君

Owner DONGGUAN CITY WONDERFUL CERAMICS IND PARK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com