Building infilled wall building block masonry equipment

A technology for filling walls and blocks, which is applied in construction, building construction, and processing of building materials, etc., can solve the problems of labor shortage, hidden safety hazards and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

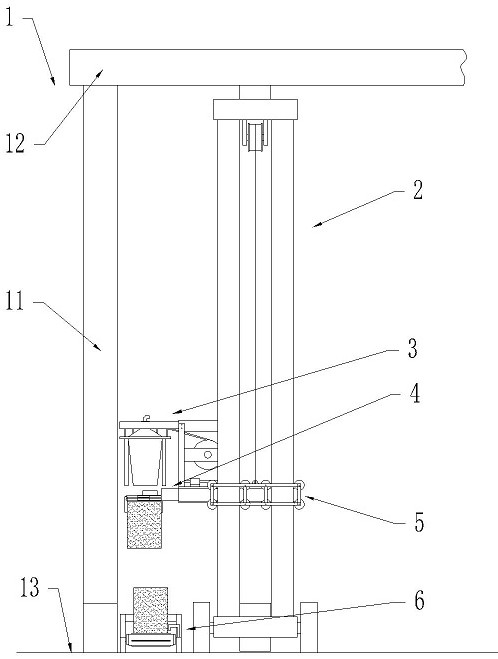

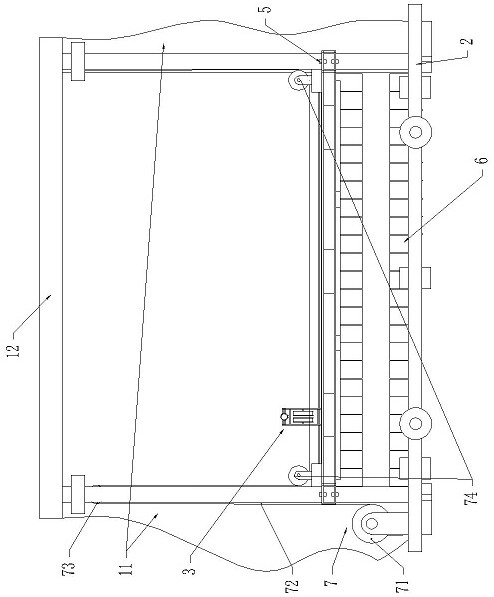

[0053] like Figure 1-11As shown in the figure, a block masonry equipment for building infill walls can realize three functions of block transfer, lifting and in-place installation; including a block transfer system 6, a block lifting frame system 2, a lifting platform system 5, and a lifting platform Drive system 7, block grabbing system 4, horizontal scraping mortar system 8, vertical smearing mortar system 3.

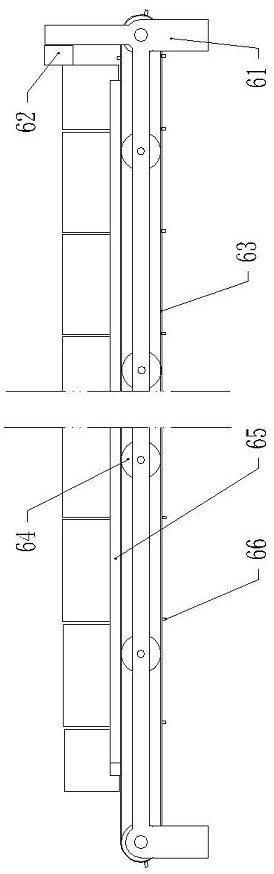

[0054] A block conveying system 6 transports the blocks to the location to be lifted; e.g. image 3 and Figure 4 As shown, it includes a conveyor belt support frame 61 , a conveyor belt 63 , a roller 64 , a vertical ash joint control block 66 , a block straightness control block 65 and a transmission limit device 62 .

[0055] The conveyor belt support frame 61 is arranged on one side of the wall to be built, and is composed of a support beam and a support leg; The conveyor belt 63 is arranged on the transmission belt support frame 6 and driven by a motor. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com