Water turbine air brake braking air pressure control self-checking device and method

A technology of air pressure control and self-checking device, which is applied in the direction of safety devices, machines/engines, mechanical equipment, etc., and can solve problems such as long pipelines, long operating time of air dampers, and air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

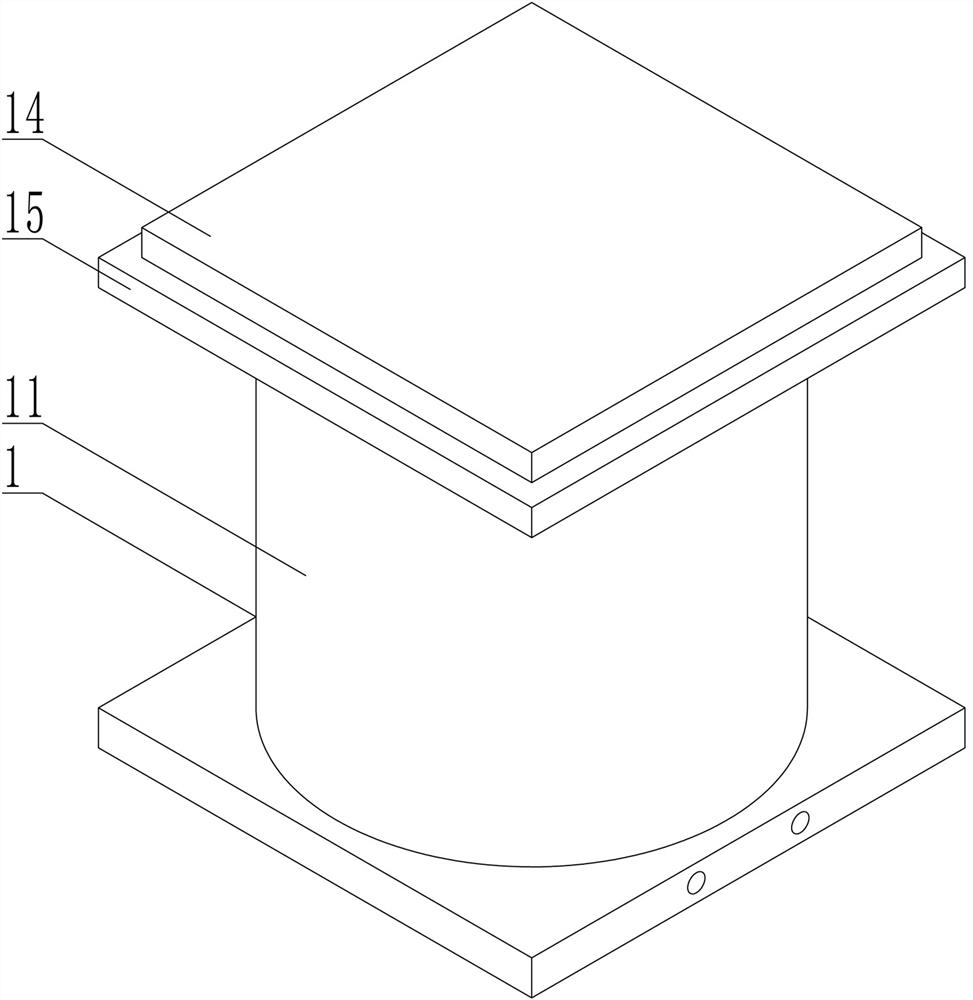

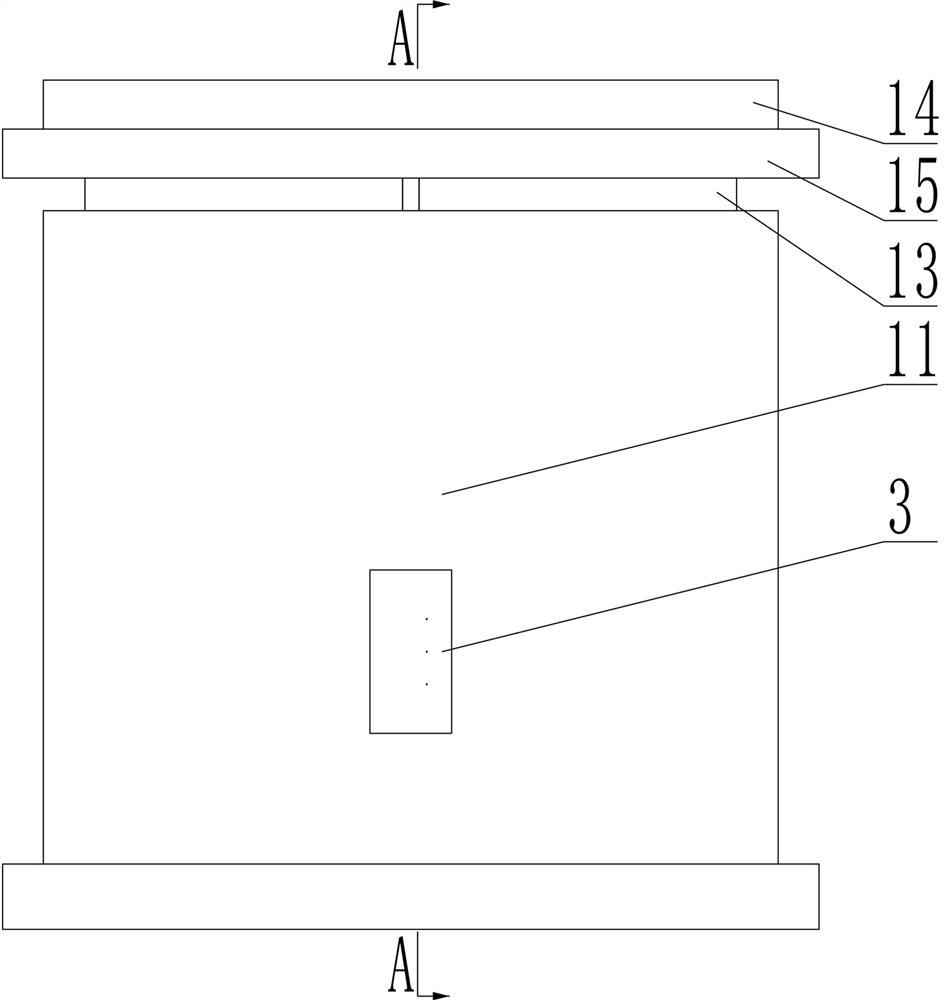

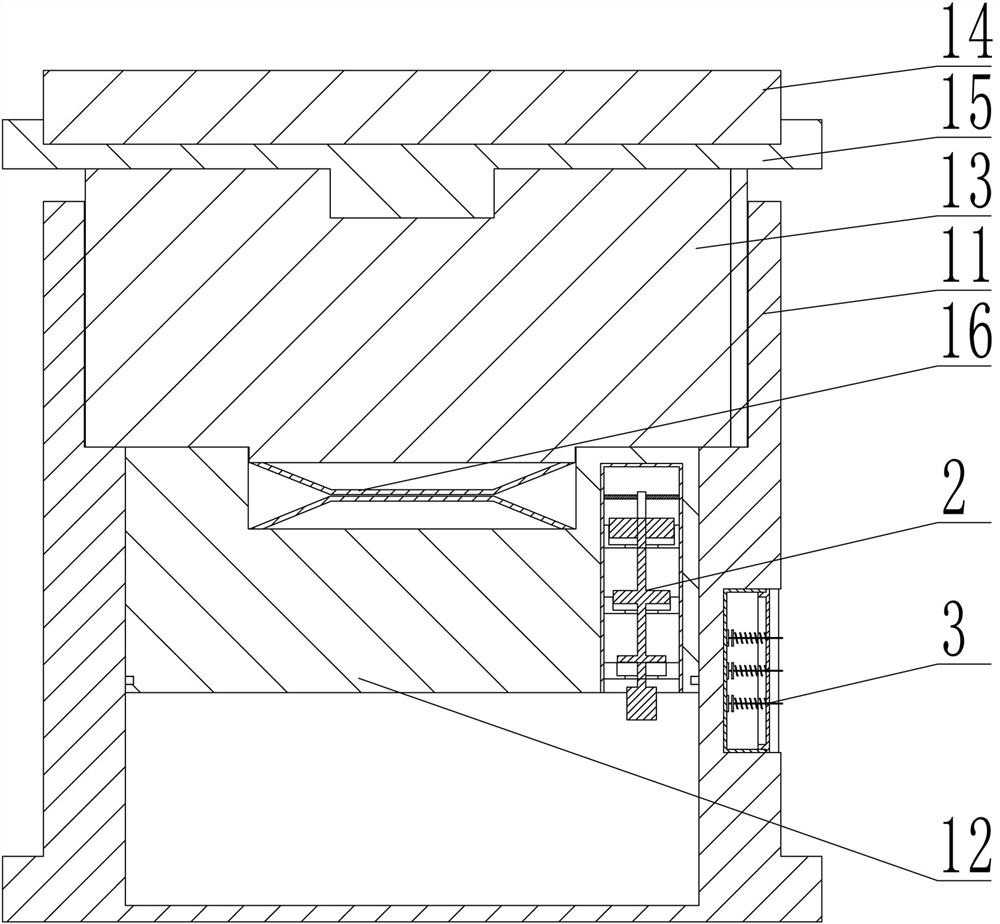

[0082] like Figure 1~Figure 8 Among them, a water turbine air brake brake air pressure control self-inspection device, which includes an air brake 1, an air pressure mechanism 2 and a contact mechanism 3; the air pressure mechanism 2 and the contact mechanism 3 are respectively located inside and outside the cylinder body 11 of the air brake 1 , the air cylinder 21 of the air pressure mechanism 2 is located in the working piston 12 of the air brake 1, and the contact box 31 of the contact mechanism 3 is located on the side of the cylinder 11 of the air brake 1; the air pressure mechanism 2 drives the moving contact of the contact mechanism 3 33 is in contact with the static contact 32. The structure is simple, by setting the pneumatic mechanism 2 inside the working piston 12 of the damper 1, and setting the contact mechanism 3 outside the working piston 12, the pressure air enters the cylinder 11 to drive the counterweight piston 24 of the pneumatic mechanism 2 to move upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com