Method and system for rapidly predicting tensile strength of Ni3Al reinforced alloy in long-term thermal exposure state

A technology of tensile strength and heat exposure, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve the problems of prolonging the cycle of material development, increasing the time cost of new materials, and time constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

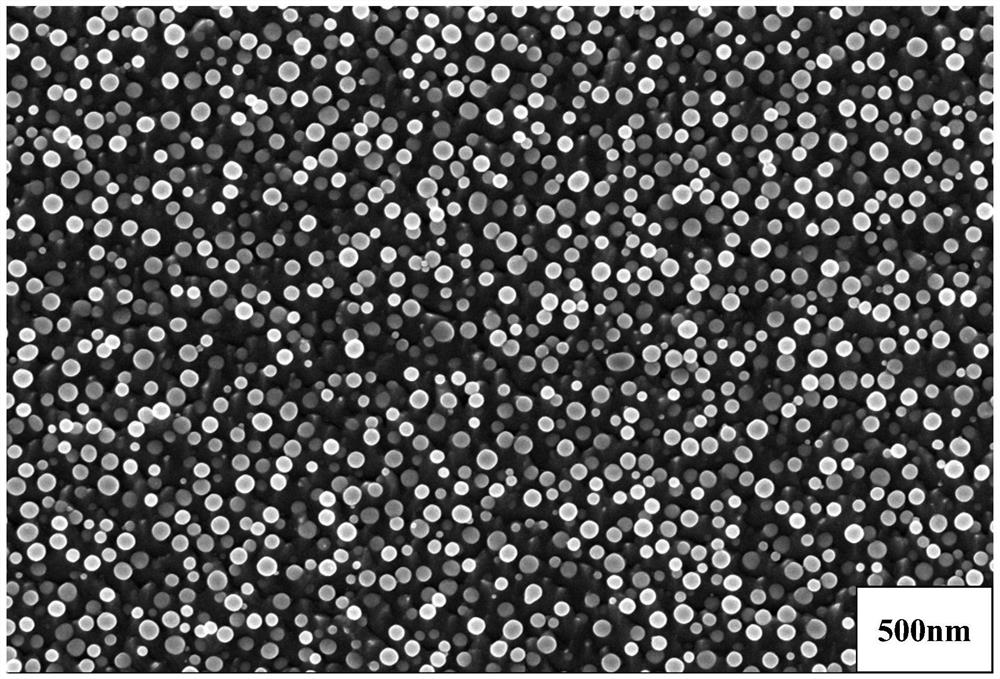

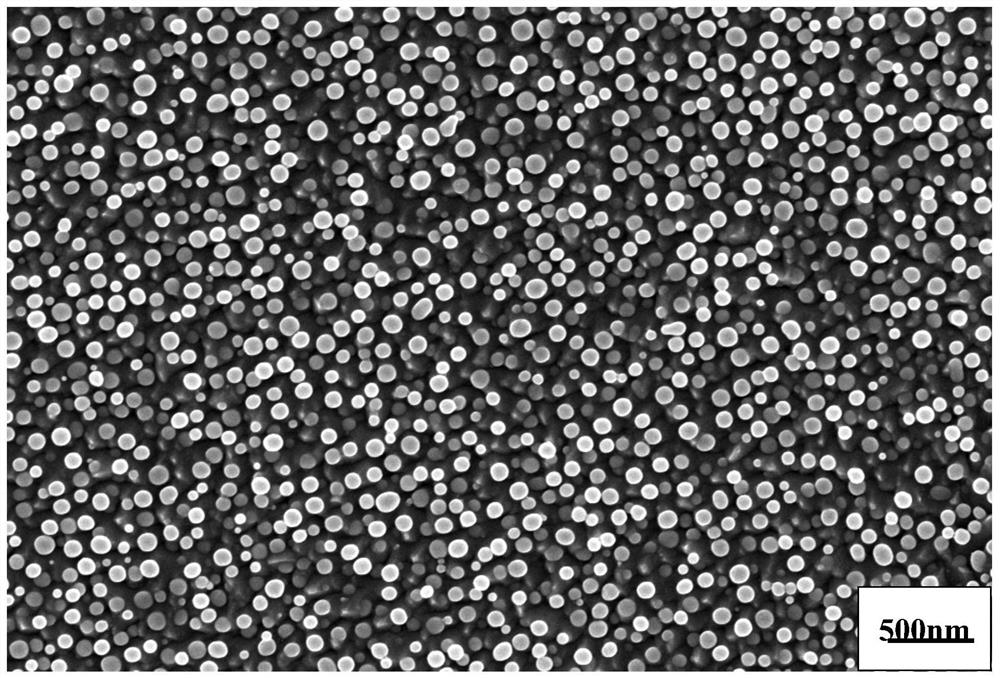

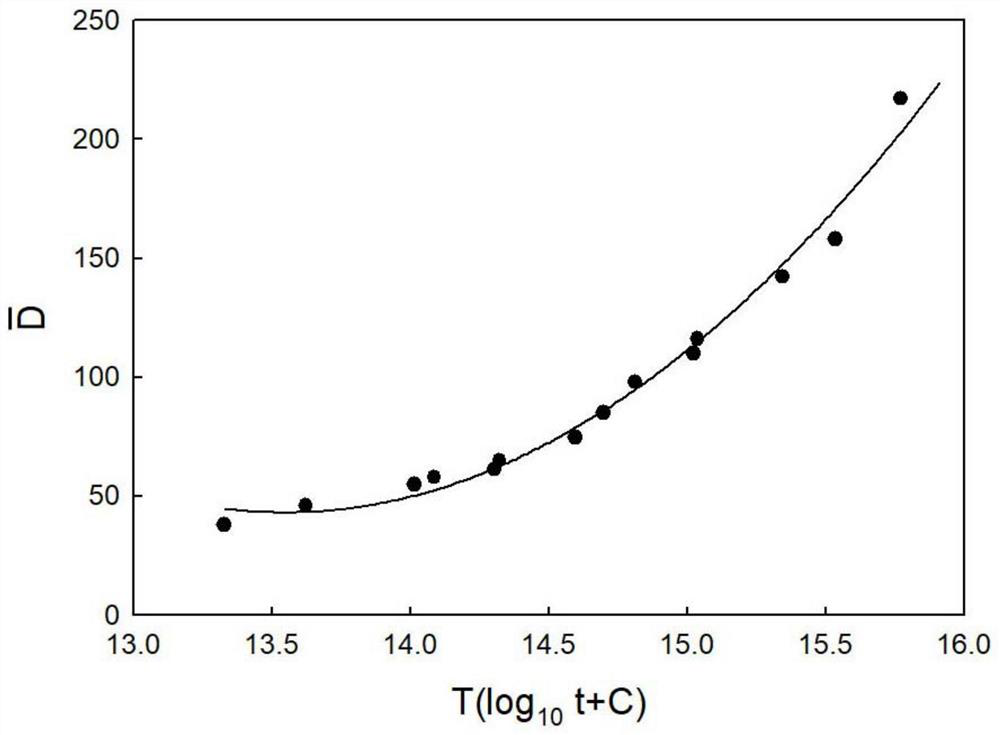

[0049] The alloy used in this implementation is a Fe-Ni based alloy, the content of the main strengthening phase Ni3Al in the grain is about 15%, and the precipitation temperature is about 930°C. Carry out 500, 1000, 3000, 5000 and 10000h heat exposure experiments on the alloy at 700 and 750°C respectively, and carry out 500, 1000, 3000, 5000h heat exposure experiments at 800°C, and establish the heat exposure time t, temperature T and Ni3Al phase average diameter The relationship between the three image 3 shown. Using this formula to calculate, it is found that when the alloy is subjected to a heat exposure test at 820°C for 72h, the scanning photo of its Ni3Al phase is as follows figure 1 As shown, the average diameter of the Ni3Al phase and the scanning photo of the Ni3Al phase after a long-term heat exposure experiment at 700°C / 10000h are as follows figure 2 As shown, the average diameter of the Ni3Al phase of the two is equivalent. Accordingly, tensile samples unde...

Embodiment 2

[0051] The alloy used in this implementation is a Fe-Ni based alloy, the content of the main strengthening phase Ni3Al in the grain is about 20%, and the precipitation temperature is about 950°C. The alloy was subjected to 1000 and 3000h thermal exposure experiments at 700 and 750°C, respectively, and 10, 30, and 100h thermal exposure experiments were carried out at 820°C, respectively, and the thermal exposure time t, temperature T and average diameter of Ni3Al phase were established The relationship between the three Figure 4 shown. Using this formula to calculate, it is found that the average diameter of Ni3Al phase is equivalent to the average diameter of Ni3Al phase after 750 °C / 1000h long-term heat exposure test when the alloy is subjected to 46h heat exposure test at 820 °C. Accordingly, tensile samples under the conditions of 820°C / 46h and 750°C / 1000h were prepared respectively, and their tensile properties at 700°C were tested. The results showed that the tensile s...

Embodiment 3

[0053] The alloy used in this implementation is a Fe-Ni based alloy, the content of the main strengthening phase Ni3Al in the grain is about 20%, and the precipitation temperature is about 950°C. The alloy was subjected to 1000 and 3000h thermal exposure experiments at 700 and 750°C, respectively, and 10, 30, and 100h thermal exposure experiments were carried out at 820°C, respectively, and the thermal exposure time t, temperature T and average diameter of Ni3Al phase were established The relationship between the three Figure 4 shown. Using this formula to calculate, it is found that the average diameter of Ni3Al phase after 16h heat exposure test at 820°C is equivalent to the average diameter of Ni3Al phase after 700°C / 100h long-term heat exposure test. Accordingly, tensile samples under the conditions of 820°C / 16h and 700°C / 1000h were prepared respectively, and the tensile properties at room temperature were tested. The room temperature tensile strength corresponding to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com