Optical proximity correction method, mask manufacturing method and semiconductor structure forming method

An optical proximity correction and mask technology, which is used in semiconductor/solid-state device manufacturing, optics, originals for optomechanical processing, etc., and can solve the problem that the graphics effect needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

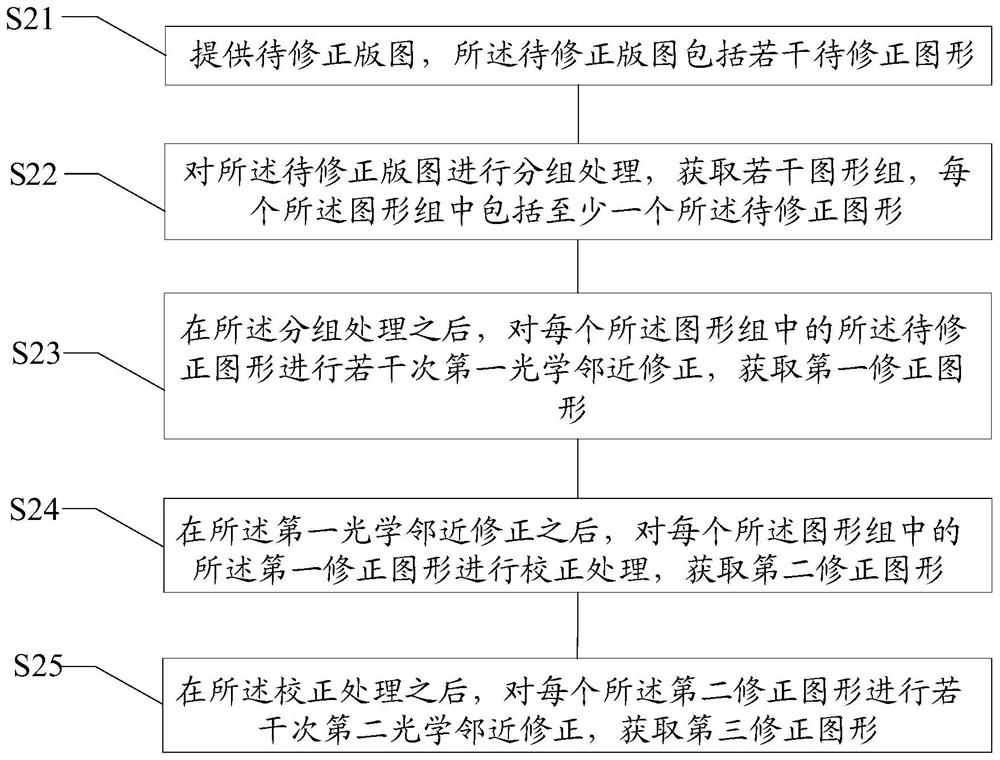

[0025] As mentioned in the background art, the graphic effect after optical proximity correction in the prior art still needs to be improved. The following will describe in detail in conjunction with the accompanying drawings.

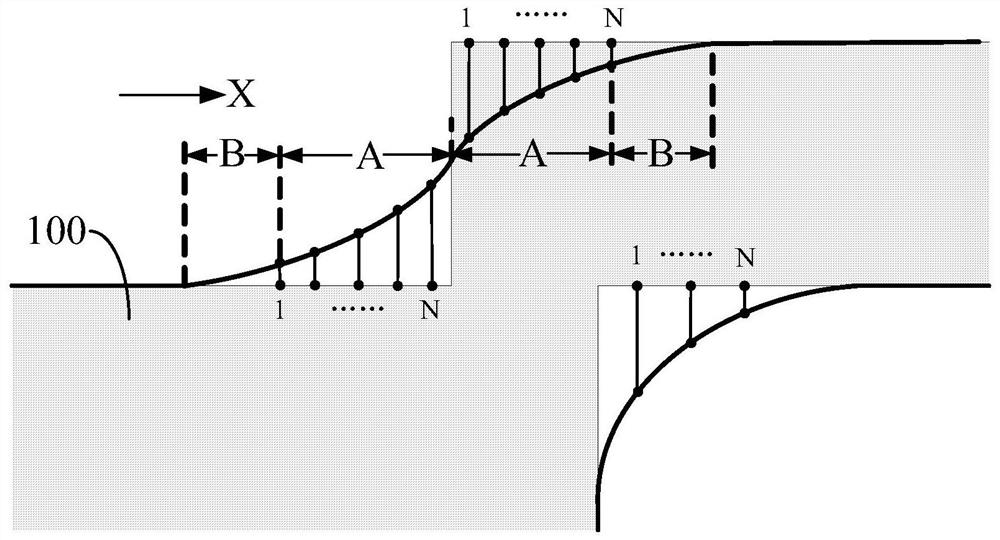

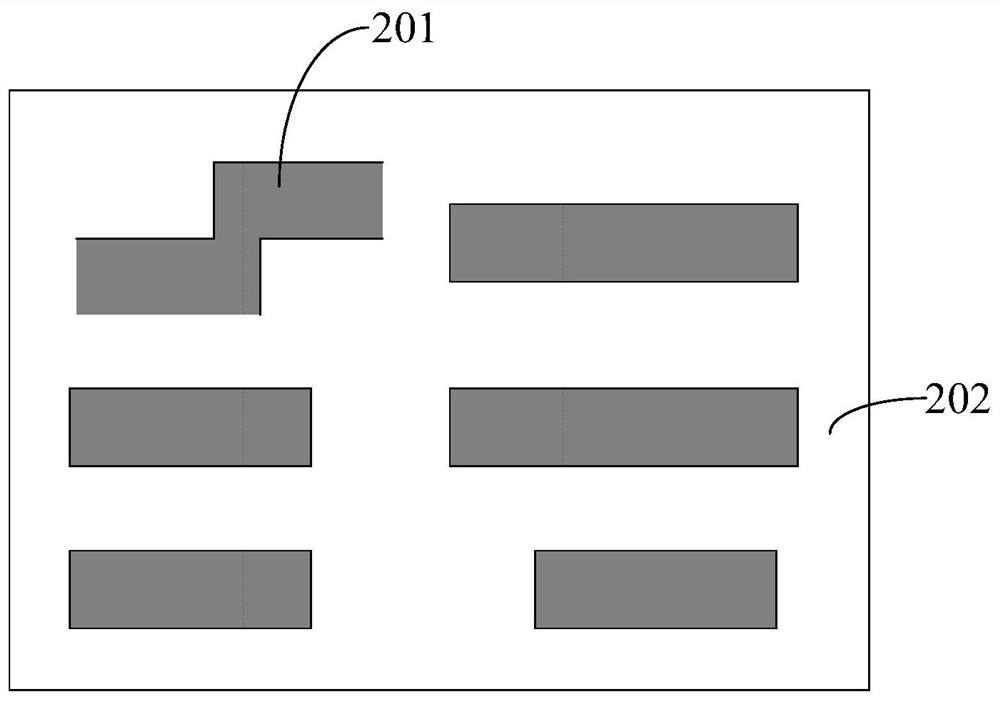

[0026] Please refer to figure 1 , provide a target layout, the target layout includes a number of target graphics 100; provide a layout to be corrected, the layout to be corrected includes a number of graphics to be corrected corresponding to the target graphics; optically perform several times on the layout to be corrected Adjacent to the correction, an intermediate layout is obtained, and the intermediate layout includes several intermediate graphics corresponding to the graphics to be corrected.

[0027] Please continue to refer figure 1 , performing exposure processing on the intermediate graphics, and obtaining the exposure graphics 101 corresponding to each of the intermediate graphics; comparing the exposure graphics 101 with the target graphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com