Processing technology of canned cassava balls

A processing technology and cassava technology, which is applied in the processing technology field of canned cassava balls, can solve the problems of gelatinization and bonding, poor integrity of stable particles, and reverse regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

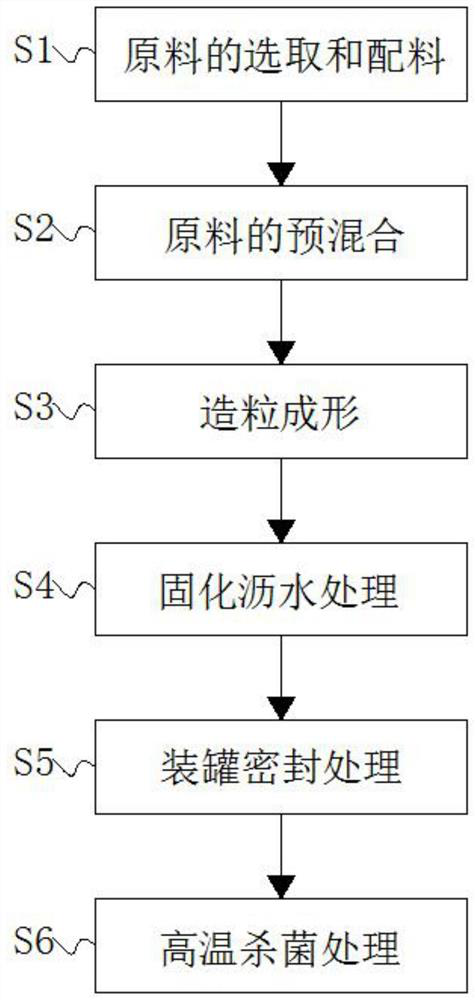

[0025] S1, the selection of raw materials and batching: First, take 55 parts of cassava flour, 15 parts of wheat flour, 4 parts of edible salt, 4 parts of vegetable oil and 7 parts of purified water respectively by the batching equipment, and mix each Raw materials are stored in storage tanks for future use;

[0026] S2. Pre-mixing of raw materials: Add cassava flour, wheat flour, edible salt, vegetable oil and purified water in the proportion of step S1 into the mixing and stirring equipment in sequence, and stir for 25 minutes at a speed of 550r / min and a temperature of 30°C. Fully mix the raw materials;

[0027] S3. Granulation and forming: transfer the mixed raw material obtained in step S2 to the granulation equipment, and make the mixed material into granules through the vibrating granulation mechanism, and then screen through the sieve, and the sieve size of all the sieves is 7 head;

[0028] S4, curing and draining treatment: transfer the cassava particles formed in ...

Embodiment 2

[0032] S1, selection of raw materials and batching: First, take 50 parts of cassava flour, 10 parts of wheat flour, 3 parts of edible salt, 3 parts of vegetable oil and 5 parts of purified water respectively by the batching equipment, and mix each Raw materials are stored in storage tanks for future use;

[0033] S2. Pre-mixing of raw materials: Add cassava flour, wheat flour, edible salt, vegetable oil and purified water in the proportion of step S1 into the mixing and stirring equipment in sequence, and stir for 20 minutes at a speed of 500 r / min and a temperature of 25°C. Fully mix the raw materials;

[0034] S3. Granulation and forming: transfer the mixed raw material obtained in step S2 to the granulation equipment, and make the mixed material into granules through the vibrating granulation mechanism, and then screen through the sieve, and the sieve size of all the sieves is 5 head;

[0035]S4, curing and draining treatment: transfer the cassava particles formed in step...

Embodiment 3

[0039] S1, the selection of raw materials and batching: First, take 60 parts of cassava flour, 20 parts of wheat flour, 5 parts of edible salt, 5 parts of vegetable oil and 10 parts of purified water respectively by the batching equipment, and mix each Raw materials are stored in storage tanks for future use;

[0040] S2. Pre-mixing of raw materials: Add cassava flour, wheat flour, edible salt, vegetable oil and purified water in the proportion of step S1 into the mixing and stirring equipment in sequence, and stir for 30 minutes at a speed of 600r / min and a temperature of 33°C. Fully mix the raw materials;

[0041] S3, granulation forming: transfer the mixed raw material obtained in step S2 to the granulation equipment, make the mixed material into granules through the vibrating granulation mechanism, and then screen through the sieve, and the sieve size of all the sieves is 10 head;

[0042] S4, curing and draining treatment: transfer the cassava particles formed in step S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com