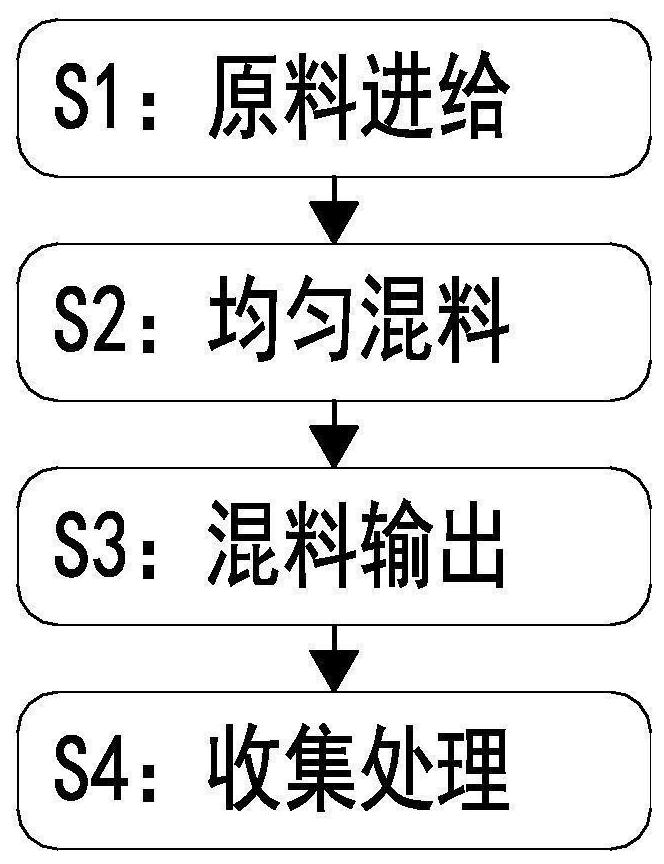

Preparation process of acrylic coating

A preparation process, a technology for acrylic acid, applied in the directions of dissolution, mixer, chemical instruments and methods, etc., can solve problems such as unfavorable energy saving and environmental protection, insufficient contact, influence ratio, etc., and achieve the effect of shortening the working cycle, saving resources and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

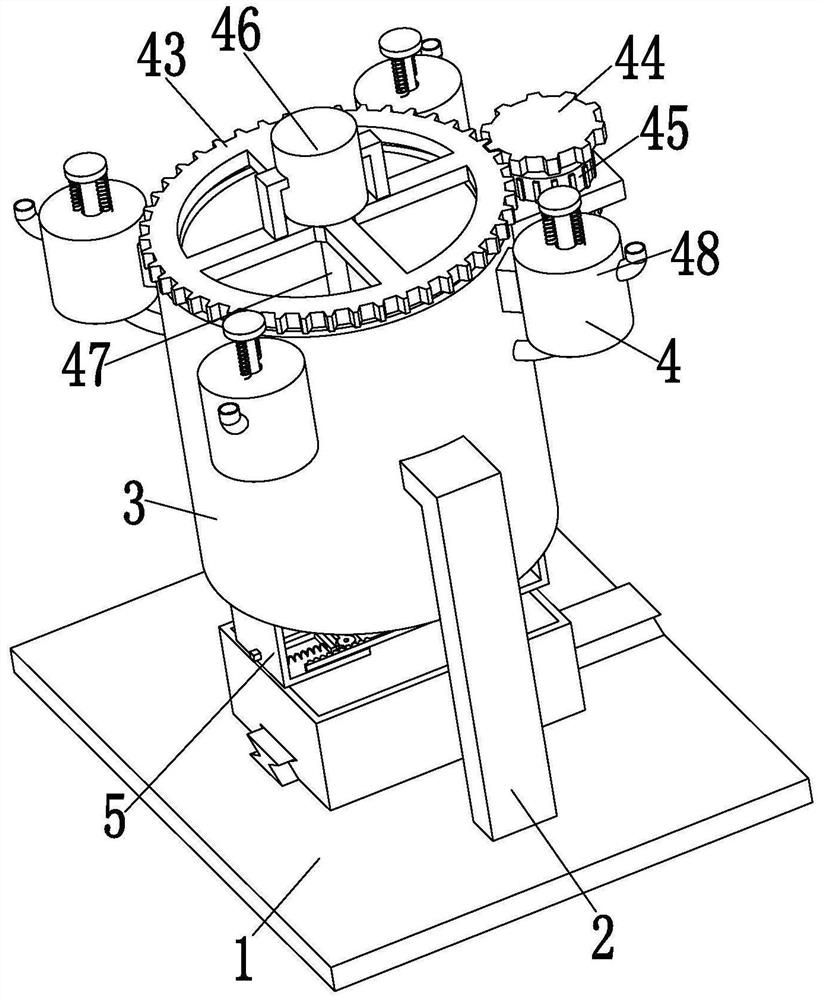

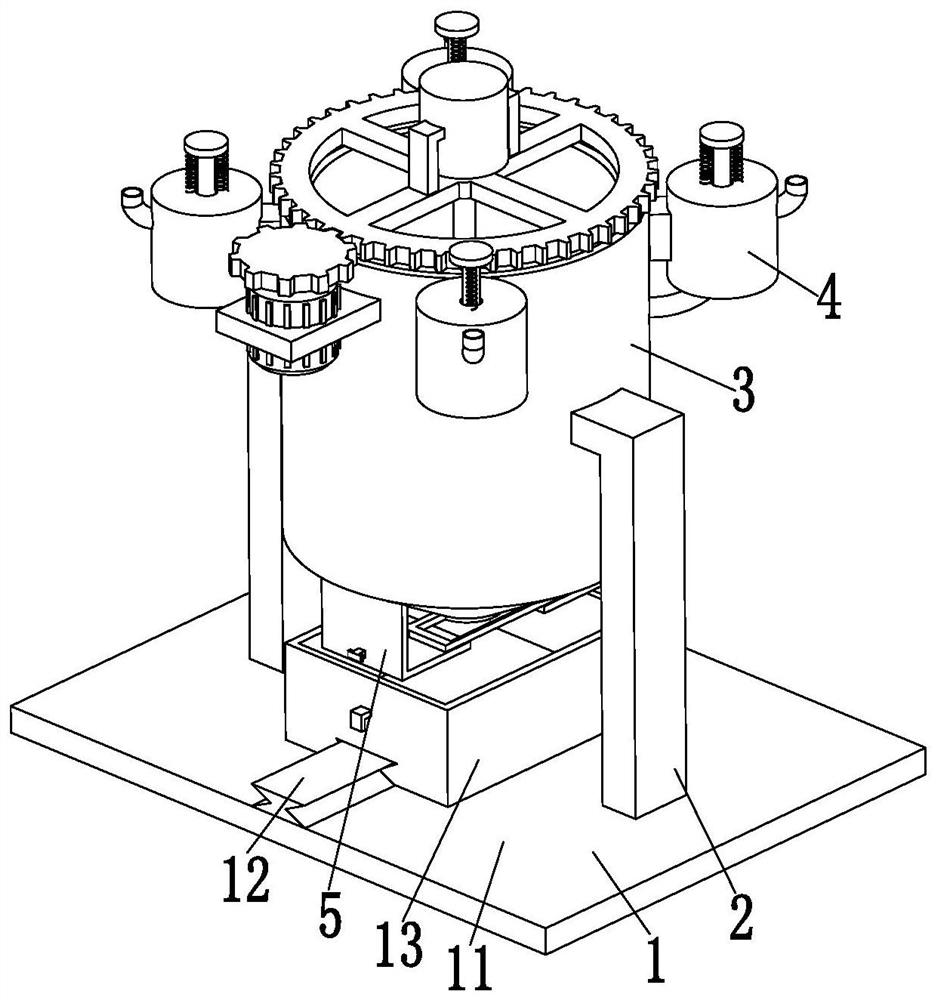

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0035] Such as Figure 1 to Figure 7 Shown, a kind of acrylic paint preparation process, it has used a kind of acrylic paint preparation machine: this machine includes fixed base 1, fixed rod 2, installation tube 3, uniform mixing device 4 and discharge device 5, described fixed The front and rear sides of the upper end surface of the base 1 are symmetrically fixed with fixed rods 2, the upper ends of the fixed rods 2 are connected with a mounting cylinder 3, the upper side of the mounting cylinder 3 is provided with a uniform mixing device 4, and the lower side of the mounting cylinder 3 is provided with Discharge device 5.

[0036]The fixed base 1 includes a fixed base plate 11, a slide rail 12 and a collection box 13, a slide rail 12 is fixed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com