NMP (N-Methyl Pyrrolidone) synthesis device

A synthesis device, a technology of monomethylamine, applied in mixers, fluid mixers, transportation and packaging, etc., can solve the problems of large equipment investment, increased operating costs, and difficult operation, and achieve larger and reduced contact area. Operating cost, effect of speeding up response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

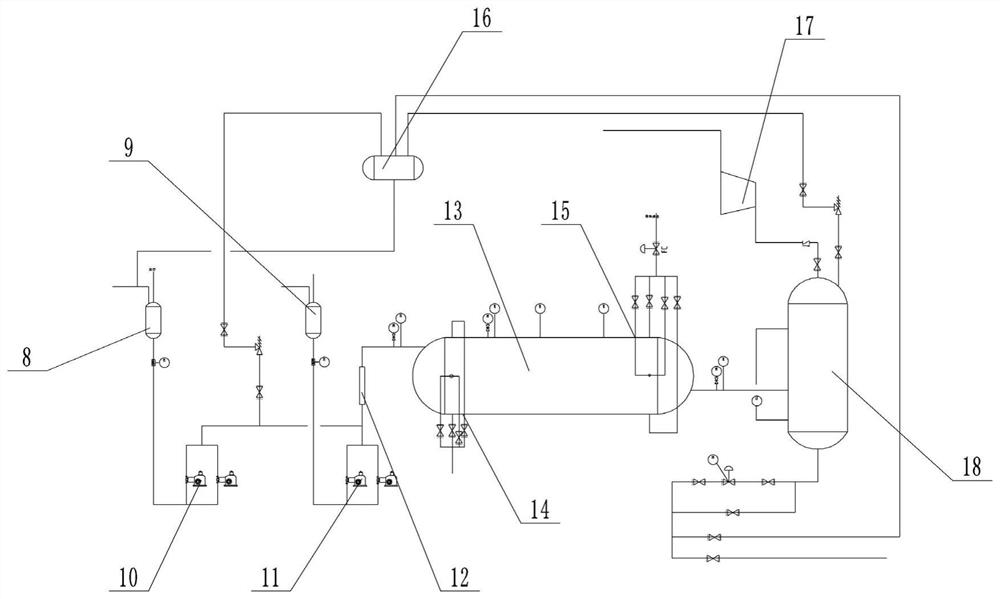

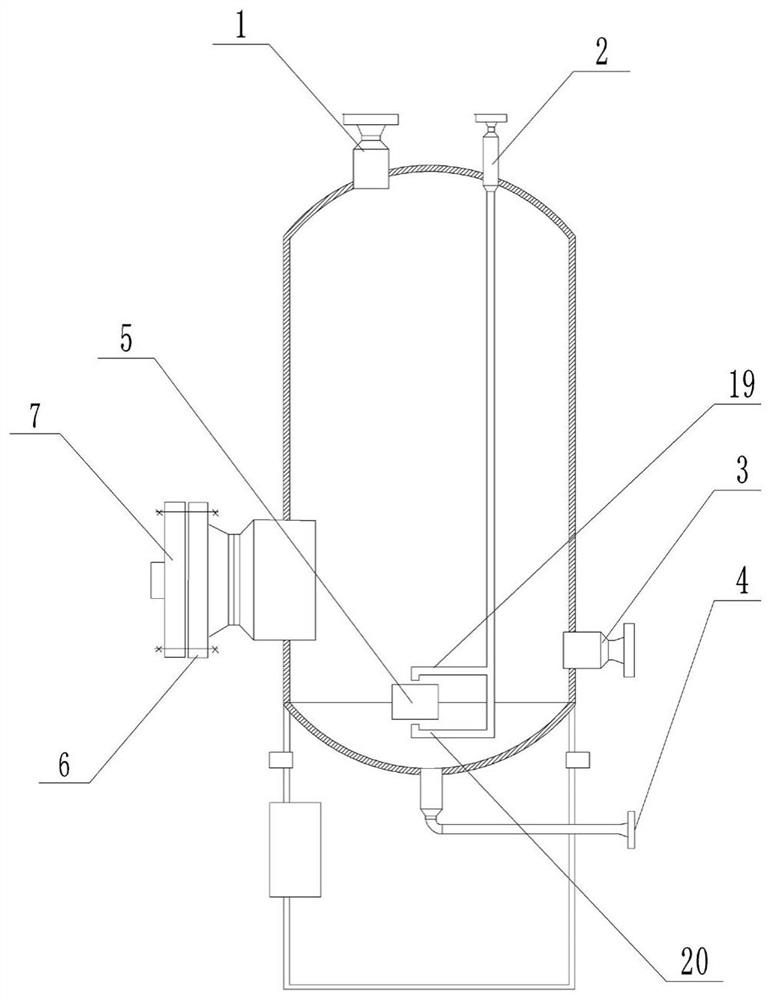

[0023] as attached figure 1 As shown, a kind of NMP synthesis device comprises GBL head tank 8, a methylamine head tank 9, GBL metering pump 10, a methylamine metering pump 11 and static mixer 12, GBL head tank 8 communicates with GBL metering pump 10, a The methylamine header tank 9 is in communication with a methylamine metering pump 11 , and the GBL metering pump 10 and a methylamine metering pump 11 are in communication with a static mixer 12 . A methylamine mixer is provided between the methylamine metering pump 11 and the static mixer 12; a GBL mixer is provided between the GBL metering pump 10 and the static mixer 12; a methylamine mixer is used to feed a methylamine metering pump 11 Provide stable materials and at the same time play a buffer role in the supply of system materials. The GBL mixer is used to provide stable materials to the GBL metering pump 10, and at the same time, it can play a buffer role in the supply of system materials.

[0024] GBL high-level tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com