Width control method and device for hot rolling width-adjusting blank

A technology of width control and width adjustment, applied in rolling mill control devices, metal rolling, length measuring devices, etc., can solve the problems of enterprise waste, waste, uneven width of width-adjusted billets, etc., to avoid production waste and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

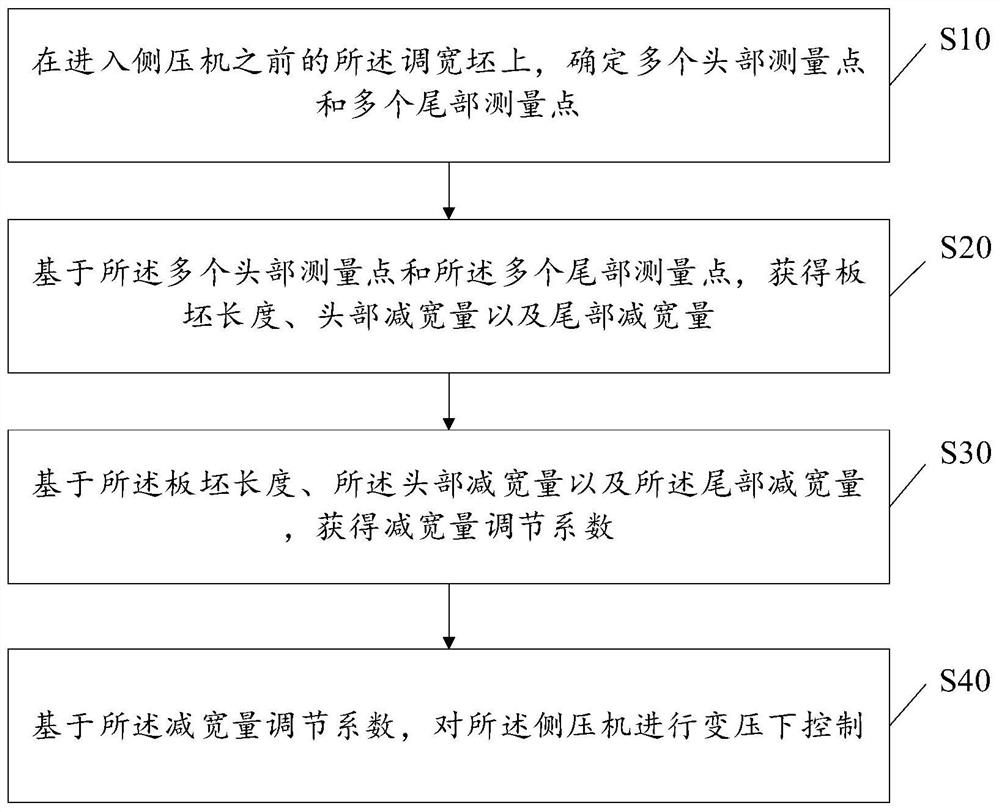

[0037] See figure 1 , figure 1 A flow chart of a method for controlling the width of a hot-rolled widening billet provided by the first embodiment of the present invention is shown. The steps that described method comprises are as follows:

[0038] Step S10: On the width-adjusting billet before entering the side press, determine a plurality of head measurement points and a plurality of tail measurement points.

[0039] In step S10 , since the side press needs to be controlled, it is necessary to measure the width of the widening billet before entering the side press. Multiple head measurement points should be close to the head position of the widening blank, and multiple tail measurement points should be close to the tail position of the widening blank. In order to avoid the influence of mutual interference of short-stroke control, the head and tail of the widening billet can be removed before determining the measurement point, that is, the specific execution of step S10 is...

no. 2 example

[0057] see Figure 5 , based on the same inventive concept, Figure 5 It shows a schematic structural diagram of a device 300 for controlling the width of a hot-rolled widening billet according to the second embodiment of the present invention. The hot-rolled billet width control device 300 includes:

[0058] The determination module 301 is used to determine a plurality of head measurement points and a plurality of tail measurement points on the width-adjusting billet before entering the side press; a first acquisition module 302 is used to determine a plurality of head measurement points based on the plurality of head measurement points. point and the plurality of tail measurement points to obtain the length of the slab, the width reduction of the head and the width reduction of the tail; the second acquisition module 303 is used to obtain the slab length, the width reduction of the head and the The tail width reduction amount is used to obtain the adjustment coefficient of...

no. 3 example

[0069] Based on the same inventive concept, the third embodiment of the present invention also provides a computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the steps of any one of the methods described in the above-mentioned first embodiment are implemented. .

[0070] It should be noted that, in the computer-readable storage medium provided by the embodiment of the present invention, the specific implementation and technical effect of each step implemented when the program is executed by the processor is the same as the foregoing method embodiment, for a brief description, For matters not mentioned in this embodiment, reference may be made to the corresponding content in the foregoing method embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com