Full-automatic steam curing equipment and method for precast concrete component

A technology of steam curing and prefabricated components, which is applied in the field of concrete prefabricated components, which can solve problems such as corner cracks, long steam curing time, and insufficient strength of concrete prefabricated components, and achieve the effects of easy operation, reduced cost, and slow turnover of formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

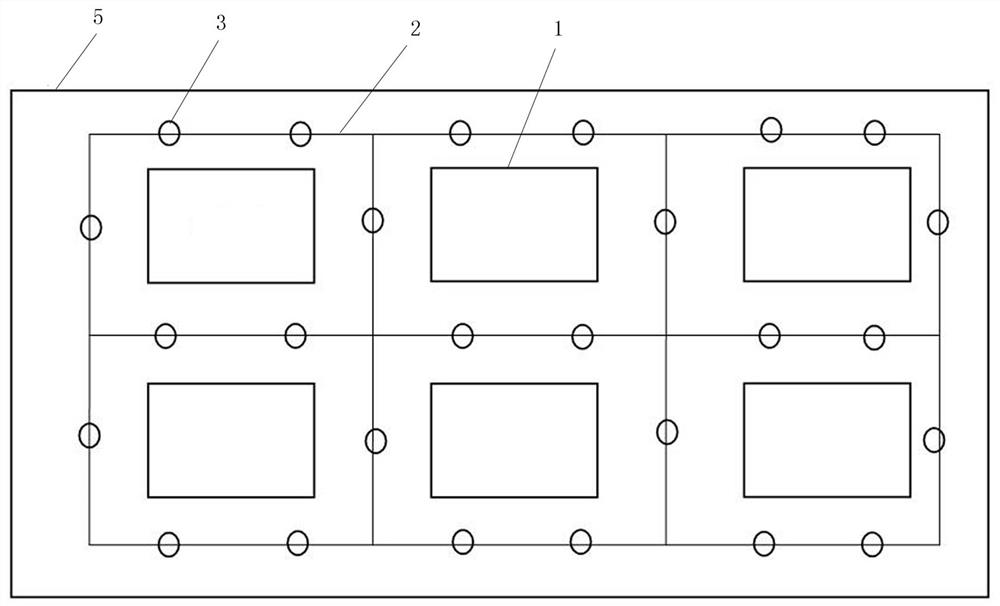

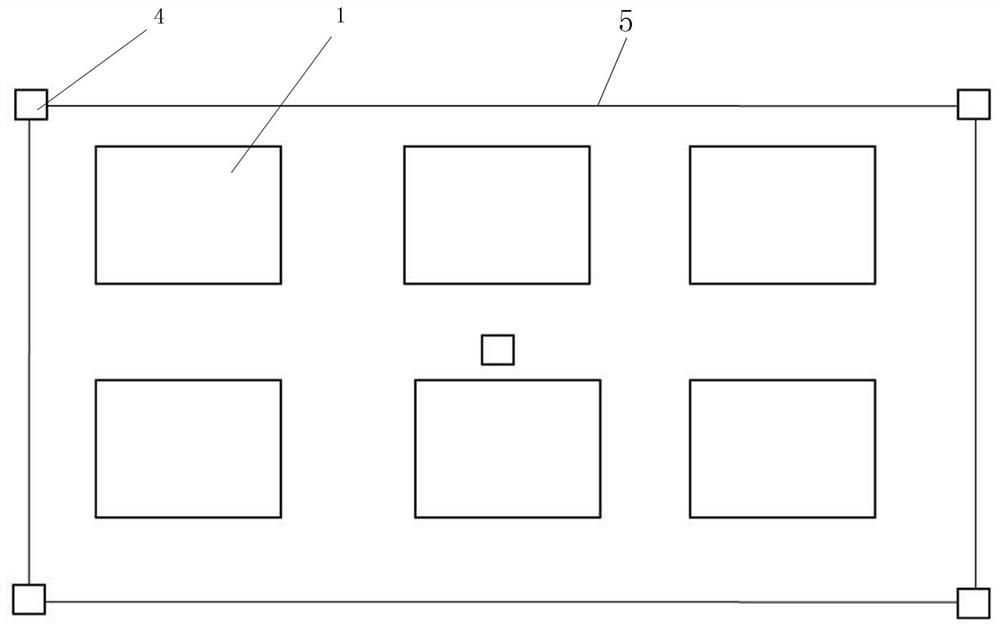

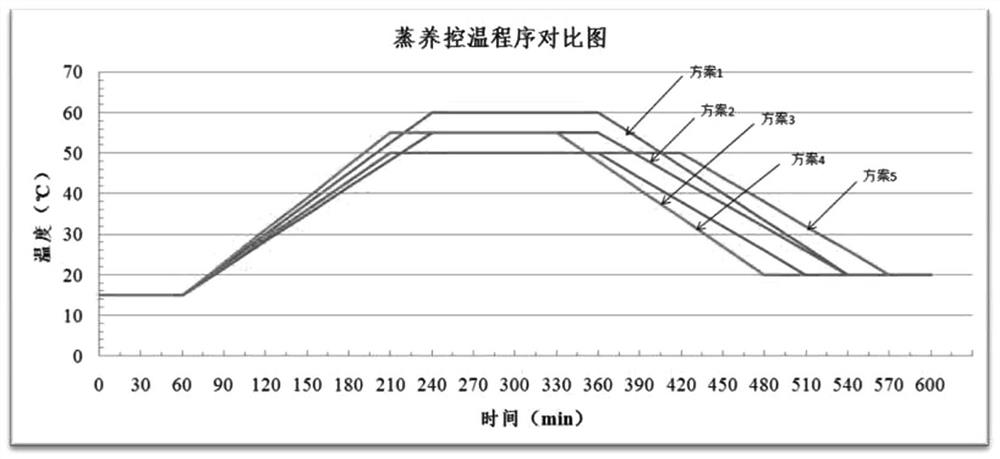

[0016] Fully automatic steam curing equipment for prefabricated concrete components 1, including a steam curing cover 5, an automatic steam curing temperature controller, an electric boiler, and a steam pipe 2 with a steam port 3 opened on it and a temperature sensor 4 inside the steam curing cover 5 , the steam pipe 2 communicates with the gas outlet of the electric heating boiler through the main pipe, the temperature sensor 4 is connected with the input end of the automatic steam curing temperature controller, and the output end of the automatic steam curing temperature controller is used to control the electric heating boiler, thereby controlling the steam curing cover The temperature within 5; there are four steam curing stages in the automatic steam curing temperature controller, which are the static stop stage, the heating stage, the constant temperature stage and the cooling stage. The static stop stage: there are parameters for the static stop temperature and the static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com