New energy electric vehicle power assembly

A technology for powertrain and electric vehicles, applied in the direction of electric power unit, power unit, vehicle components, etc., can solve the problems of lack of sealing at the pipe connection, the influence of the surrounding environment, and the leakage of coolant, so as to ensure normal use and avoid connection. The effect of enlarged mouth and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

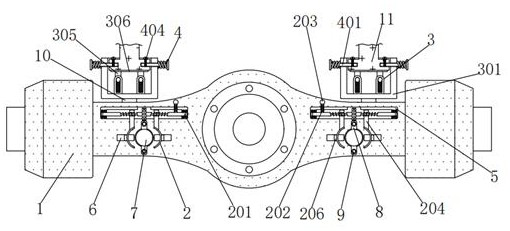

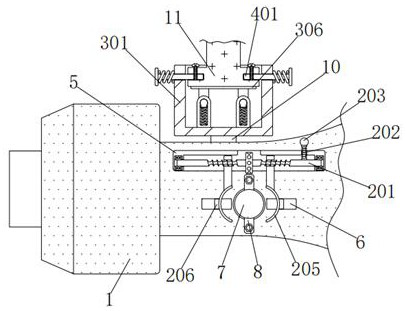

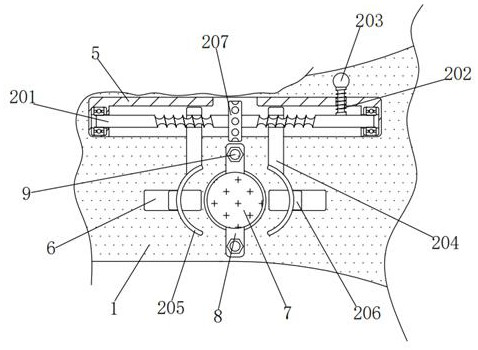

[0034] A power assembly for a new energy electric vehicle, comprising a power assembly 1, recessed plates 5 are fixedly connected to the upper left and right sides of the front of the power assembly 1, a fixing mechanism 2 is installed inside the two concave plates 5, and the fixing mechanism 2 comprises double-ended stud 201, threaded rod 202, ball 203, vertical plate 204, arc plate 205, square 206 and disc 207, the left and right sides of the outer wall of double-ended stud 201 and the inner wall left and right sides of concave plate 5 respectively. The side rotation is connected, and the double-ended stud 201 is forced to rotate through the bearings on the left and right sides of the inner wall of the concave plate 5, and the top on the right side of the outer wall of the double-ended stud 201 is pressed against the bottom of the threaded rod 202 to prevent the double-ended stud 201 from rotating. The outer wall of the threaded rod 202 is threadedly connected with the top ri...

Embodiment 2

[0036] As an option, see figure 1 , 2 , 5 and 6, the new energy electric vehicle powertrain, the front of the powertrain 1 is connected with a pipeline 7, the upper and lower sides of the pipeline 7 are fixed with square plates 8, and the inner walls of the two square plates 8 are passed through the second bolts respectively 9 is threadedly connected to the front of the power assembly 1, and the outer wall of the disc 207 is equidistantly processed with round openings, which are convenient for the rotation of the disc 207. Backing plates 10 are fixedly connected to the left and right sides of the top of the power assembly 1, two The top of backing plate 10 is equipped with buffer mechanism 3, and buffer mechanism 3 comprises shell 301, groove plate 302, first spring 303, circular plate 304, short plate 305 and straight plate 306, and the bottom of shell 301 and the bottom of backing plate 10 are connected. Fixed connection, the left and right sides of the bottom of the inner ...

Embodiment 3

[0039] As an option, see figure 1 , 2, 5 and 6, the new energy electric vehicle powertrain, the upper left and right sides of the two casings 301 are equipped with a clamping mechanism 4, the clamping mechanism 4 includes a straight rod 401, a vertical plate 402, a second spring 403 and a first Bolt 404, the outer wall of straight rod 401 and the upper left side of housing 301 clearance fit, and straight rod 401 moves left and right through upper left side of housing 301 under force, and the left side of straight rod 401 is fixedly connected with the right side of stand plate 402, directly The outer wall of the rod 401 is socketed with the inner wall of the second spring 403, and the left and right sides of the second spring 403 are fixedly connected with the right side of the vertical plate 402 and the upper left side of the housing 301 respectively, and the straight rod 401 moves under force and passes through The second spring 403 rebounds, and the right side of the straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com