A belt conveyor intelligent idler group with self-inspection function

A technology of belt conveyor and idler group, applied in the direction of conveyor, conveyor object, conveyor control device, etc., can solve the problems of long transportation distance, no practical use, difficult practical application, etc., to increase the utilization rate , the effect of reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

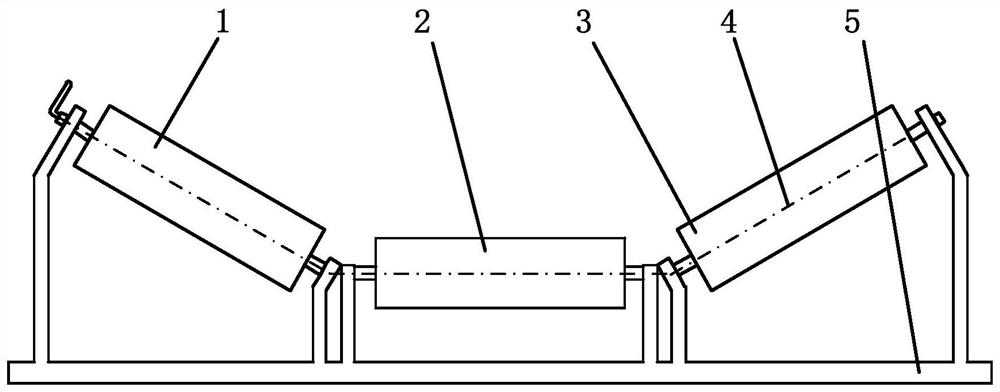

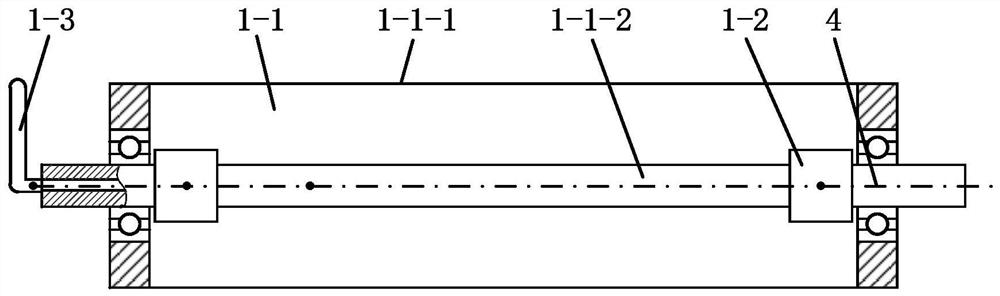

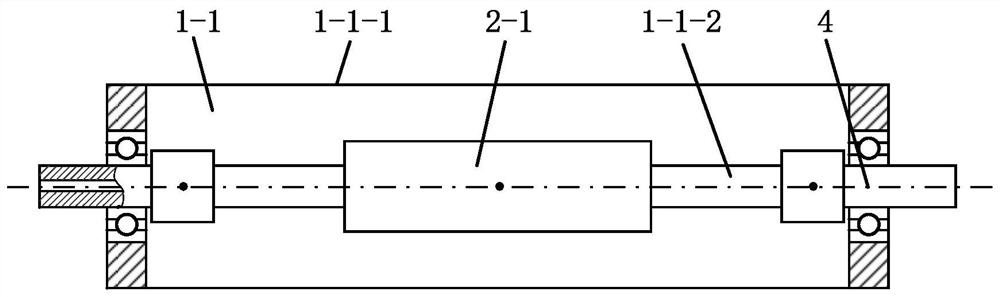

[0022] like figure 1 As shown, the present invention proposes a belt conveyor intelligent idler group with self-checking function, including communication rollers 1 , data processing rollers 2 , power generation rollers 3 , power supply and data lines 4 and idler racks 5 . The communication roller 1 , the data processing roller 2 and the power generation roller 3 are all mounted on the idler frame 5 and connected to each other by a power supply and data line 4 . Because the various functional modules of the idler group must have electric power supply to operate normally, and some belt conveyors are difficult to contact the middle idler under no-load or light-load conditions, it will cause the power generation function of the power generation roller 3 due to the idler. Therefore, the power generation roller 3 should not be insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com