Wearable thermoelectric bracelet and preparation method thereof

A wristband and thermoelectric technology, which is applied in the manufacture/processing of thermoelectric devices, bracelets, watch straps, etc., can solve the problem of inability to match the direction of human heat flow, and achieve the effects of improving the utilization rate of temperature difference, increasing efficiency, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

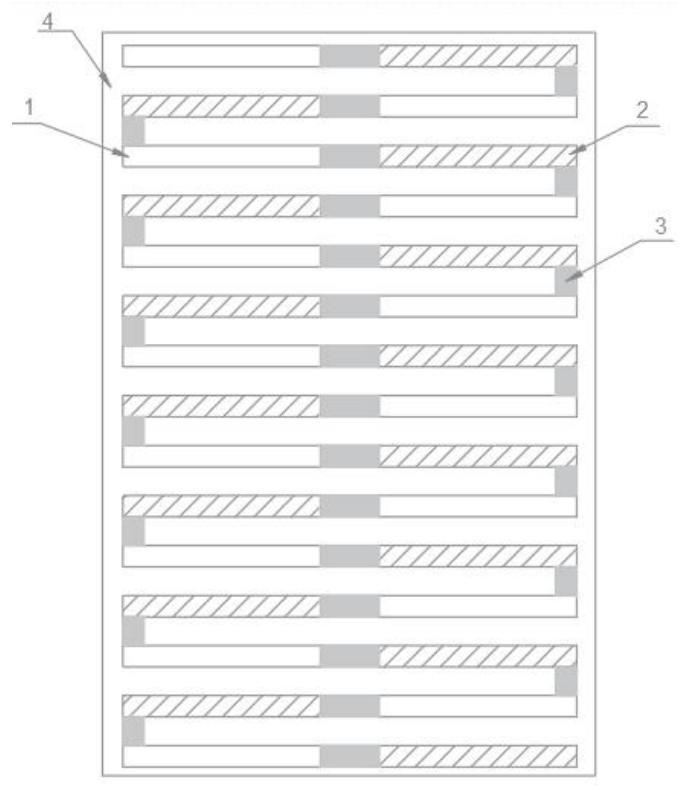

[0046] The embodiment of the present invention also provides a preparation method of a wearable thermoelectric wristband, the method comprising the following steps:

[0047] S1. Add 0.05-0.2 g of N-type material, 3-10 wt % of dispersant cetyl trimethyl ammonium bromide and 5-15 wt % of polyurethane into 5-20 ml of solvent, ultrasonically and stirred to prepare N-type paint. Specifically, the N-type material adopts one of nitrogen-doped multi-walled carbon nanotubes, bismuth telluride, and nitrogen-doped graphene, and is dispersed in an aqueous solution to make a slurry, and the addition of 5-15wt% of polyurethane improves its performance. film-forming. Preferably, the concentration of nitrogen-doped multi-walled carbon nanotubes in the N-type coating is in the range of 5-15 mg / mL.

[0048] S2. Add 5-10V% dimethyl sulfoxide into 2-10ml of P-type material and stir to prepare P-type paint. Specifically, the P-type material is a commercialized PEDOT:PSS aqueous dispersion, and ...

example 1

[0052] 1. Add 1g CTAB (dispersant cetyltrimethylammonium bromide) to 19ml deionized water to prepare a CTAB aqueous solution with a mass fraction of 5%; add 2g WPU (polyurethane) to the CTAB aqueous solution and wait for it to disperse evenly After that, 10 wt% nitrogen-doped multi-walled carbon nanotubes (N-MWCNTs) were added, ultrasonicated for 1 h, and then stirred for 2 h to prepare an N-type coating.

[0053] 2. Add 0.2 ml of dimethyl sulfoxide (DMSO) to 2.8 ml of poly-3,4-ethylenedioxythiophene:polystyrene sulfonic acid (PEDOT:PSS) and stir for 24 hours to obtain a P-type coating.

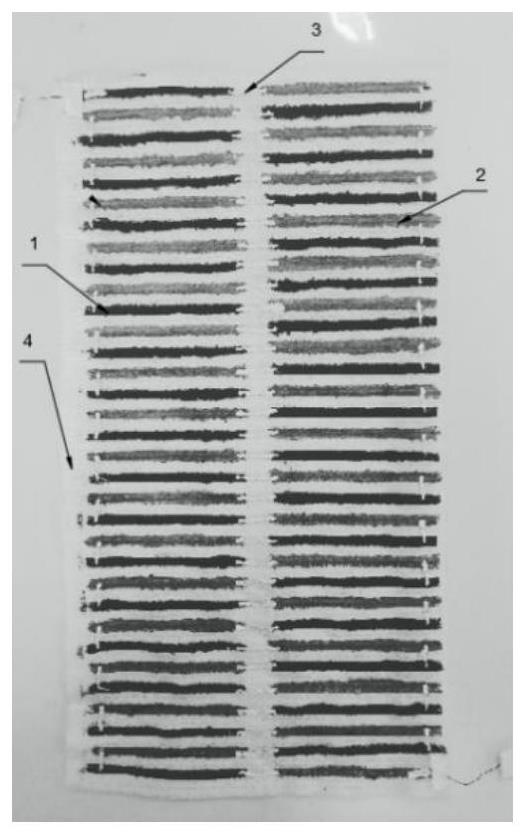

[0054] 3. Through the pre-prepared mask, the P-type coating and the N-type coating are sequentially coated on the substrate in an array with a brush, and then the P and N-type thermoelectric coatings are sequentially connected with silver glue to form a electrical series path.

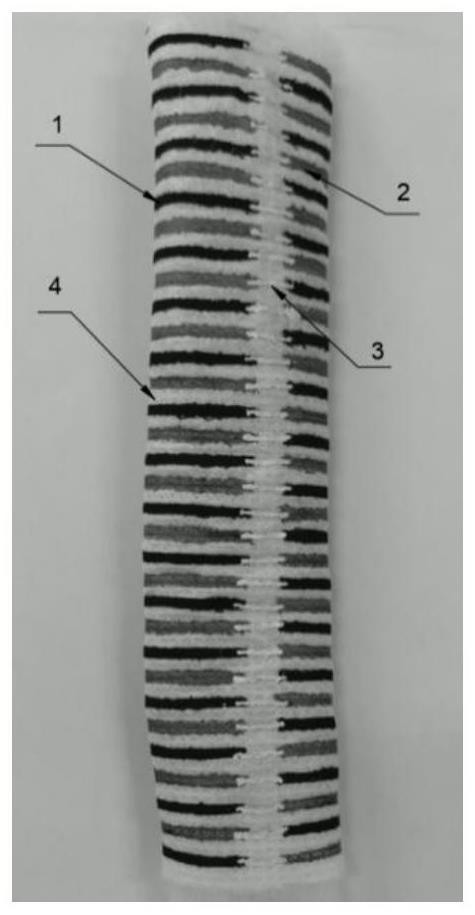

[0055] 4. The flexible fiber paper substrate coated with thermoelectric material is folded back along both sides o...

example 2

[0058] 1. Add 1 g of CTAB to 19 ml of deionized water to prepare a CTAB aqueous solution with a mass fraction of 5%; add 2 g of WPU to the CTAB aqueous solution, and after it is uniformly dispersed, add 5 wt% of nitrogen-doped multi-walled carbon nanotubes (N- MWCNTs), sonicated for 1 h, and then stirred for 2 h to prepare an N-type coating.

[0059] 2. Add 0.2 ml of dimethyl sulfoxide (DMSO) to 2.8 ml of poly-3,4-ethylenedioxythiophene:polystyrene sulfonic acid (PEDOT:PSS) and stir for 24 hours to obtain a P-type coating.

[0060] 3. Through the pre-prepared mask, the P-type coating and the N-type coating are sequentially coated on the substrate in an array with a brush, and then the P and N-type thermoelectric coatings are sequentially connected with silver glue to form a electrical series path.

[0061] 4. The flexible fiber paper substrate coated with thermoelectric material is folded back along both sides of the midline and sewed with needles and threads to form a strip;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com