Automatic furnace pressing control method and system in tapping process

A technology of tapping process and control method, which is applied in the direction of manufacturing converters and improving process efficiency, etc. It can solve problems such as slag in the tapping hole, low molten steel level, and unstable accuracy of manual operation, so as to reduce slag tapping , highly suitable, and the effect of improving the degree of automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

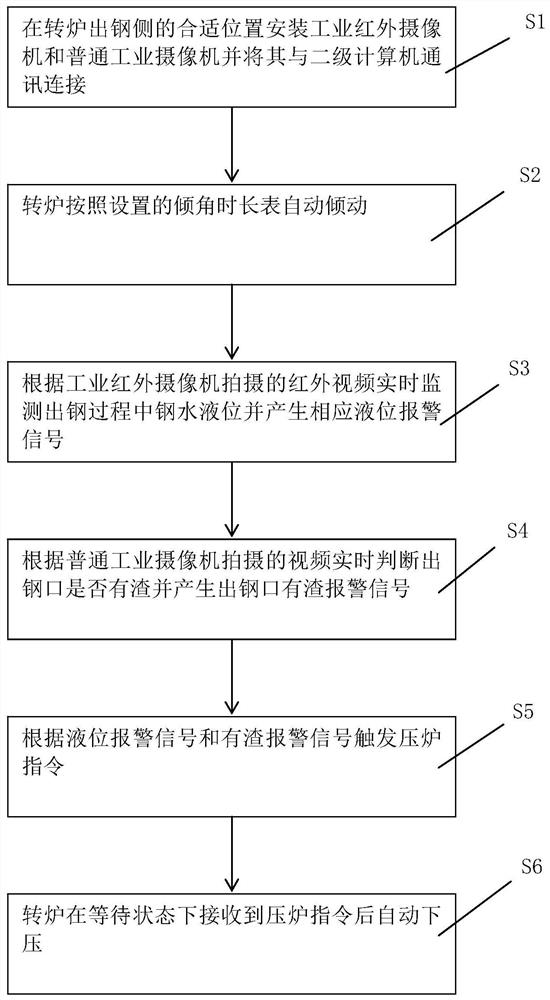

[0037] Such as figure 1 As shown, an automatic press furnace control method in a converter tapping process may include the following steps:

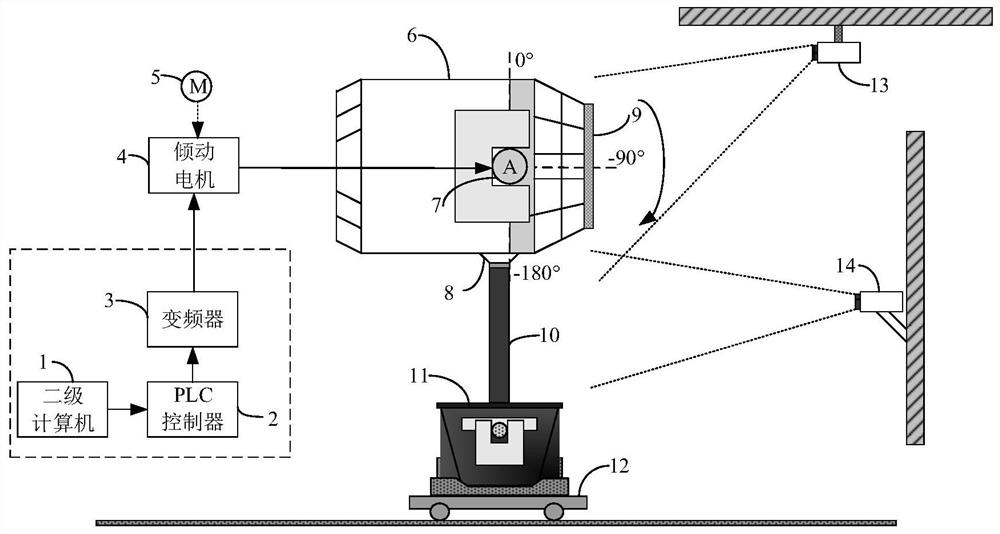

[0038] S1, install industrial infrared camera 13 and common industrial camera 14 to shoot video at the suitable position of converter 6 tapping side and communicate with secondary computer 1, see figure 2 .

[0039] Cameras are installed at appropriate positions on the tapping side of the converter to replace manual visual observation. Specifically, an industrial infrared camera is installed at the top of the higher platform on the tapping side of the converter, and the lens angle and focal length are adjusted to capture the furnace mouth of the converter as clearly as possible during tapping. At the same time, an ordinary industrial camera is installed at a lower position on the tapping side of the convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com