Full-shaft heat-insulation electric submersible pump injection-production integrated pipe column applied to 370-DEG C thermal production well and operation method thereof

An electric submersible pump and thermal recovery well technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of high workover cost, leakage, and sound steam injection effect, etc., to ensure production safety. , Guarantee operation safety, improve the effect of thermal recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

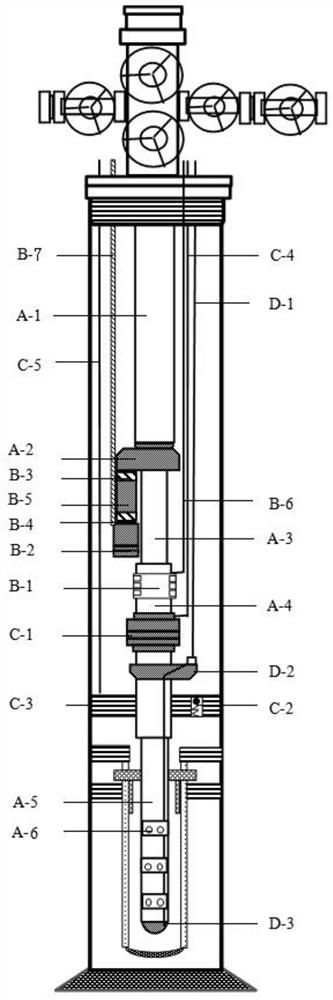

[0030] as attached figure 1 As shown, the present invention discloses a full-bore heat-insulated electric submersible pump injection-production integrated string applied to 370-degree thermal recovery wells, mainly including a steam injection process system, a lifting process system, a safety control system, and a downhole monitoring system .

[0031] The upper part of the Y joint A-2 is connected to the 4-1 / 2" heat-insulated oil pipe A-1, and the high-temperature electric pump unit B-2 is connected to the pump front II and the check valve B-4, and the heat-insulated short The connection B-5 is connected to the first-stage check valve B-3 in front of the pump, and the first-stage check valve B-3 in front of the pump is connected to the lower end of the Y joint A-2 to form a lifting channel.

[0032] The upper end of the small-diameter heat-insulated oil pipe A-3 is connected to the lower end of the Y joint A-2, and the lower end is connected to the 4-1 / 2" heat-insulated oil p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistant | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com