Triaxial sample batch manufacturing device and method capable of performing dry-wet cycle

A dry-wet cycle, triaxial sample technology, applied in the measurement device, the preparation of test samples, sampling, etc., can solve the problem that the triaxial sample preparation device cannot perform dry-wet cycle, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

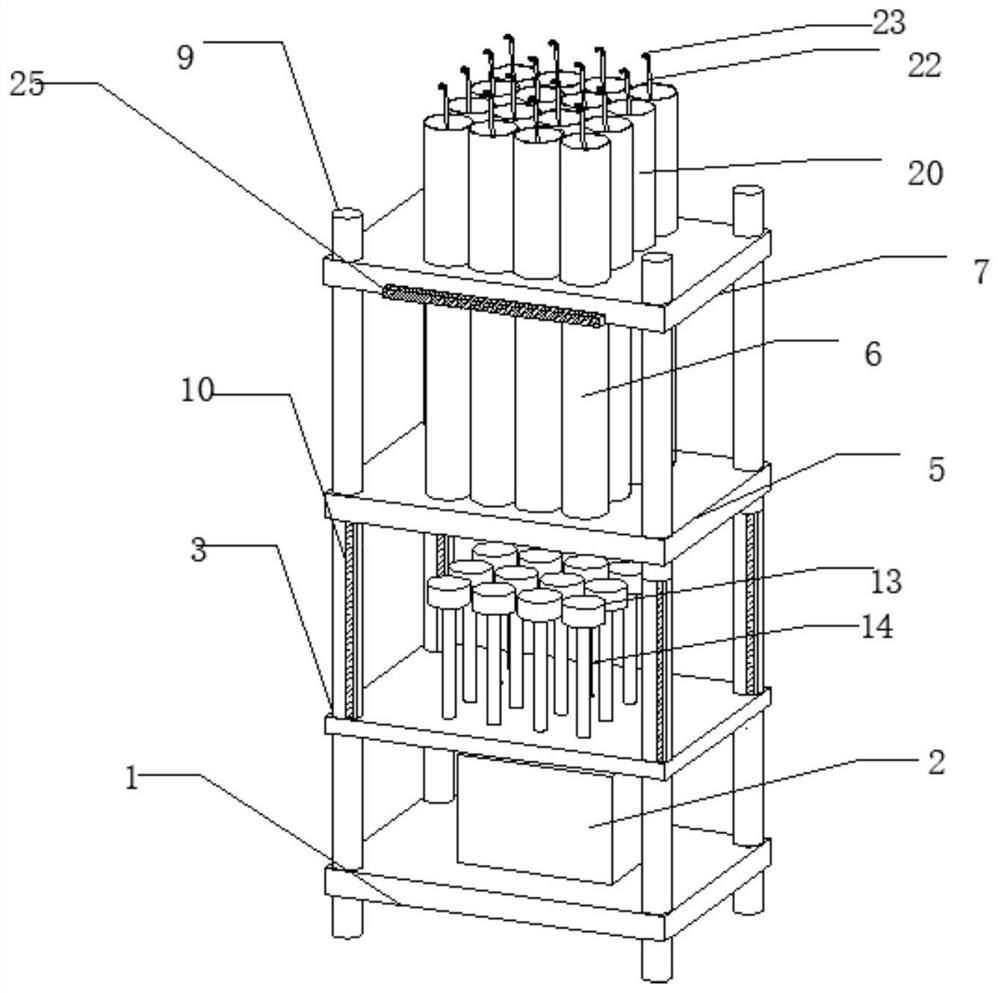

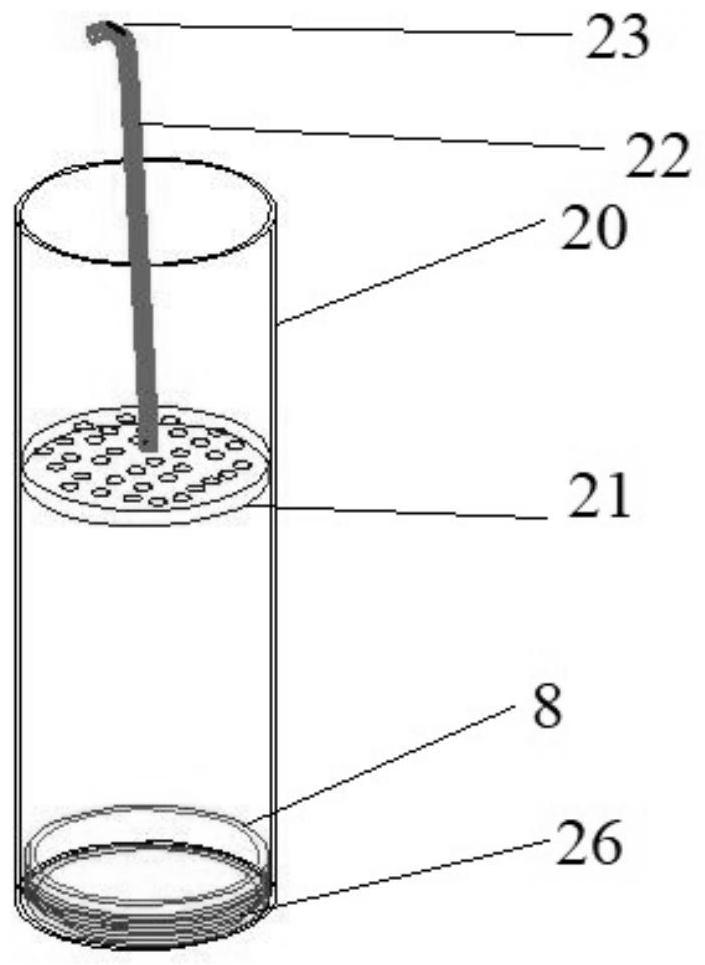

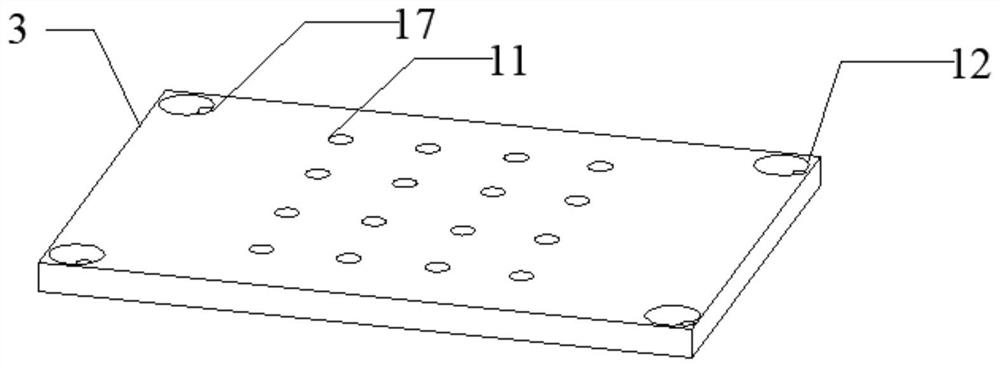

[0048] like figure 1 , 8 As shown, the device as a whole includes four steel pipes 9 with a diameter of 5 cm. A groove 10 with a width of 1 cm, a depth of 1 cm, and a length of 30 cm is provided in the middle of the steel pipes, so that the subsequent plate rises along the grooves through the pulley, and the bottom of the steel pipes has threads 26 The top of the steel pipe is provided with a plurality of fixed circular holes 18 with a diameter of 2 cm along its length direction. The four steel pipes are all parallel to each other and vertically arranged. The four steel pipes are connected with a bottom plate 1, a plate 3, Plate two 5 and top plate 7.

[0049] like Image 6 , the four corners of the base plate are respectively provided with a base plate connecting hole 15 with a diameter of 5cm, the base plate connecting hole has threads, the steel pipe bottom stretches into the base plate connecting hole and is threadedly connected with it, and the base plate is provided wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com