Light-transmitting color diaphragm, manufacturing method thereof and capacitive touch color diaphragm

A manufacturing method and color film technology, applied in the directions of copying/marking method, film/sheet release coating, film/sheet adhesive, etc., can solve the problem of poor product production, complicated production process, complicated operation process, etc. problems, to achieve the effect of saving labor costs, good light transmission effect, and improving sensory needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

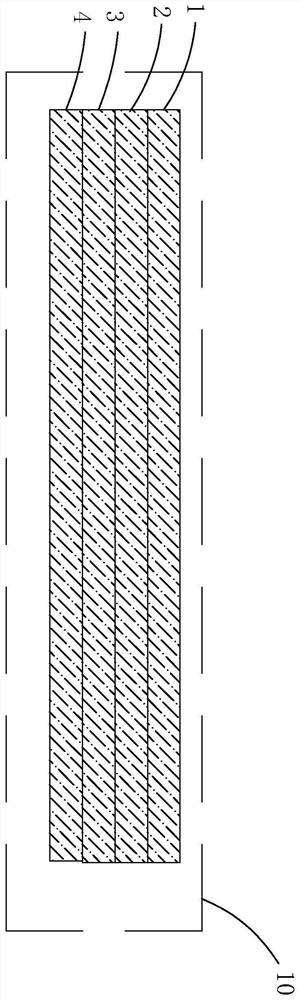

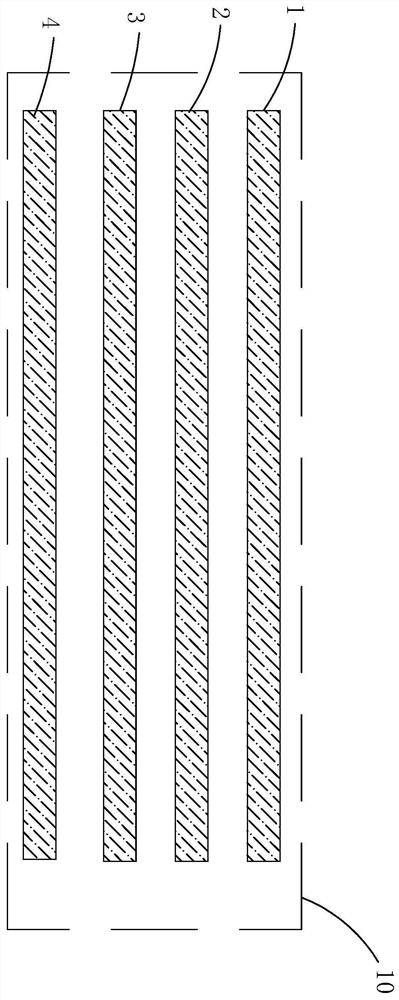

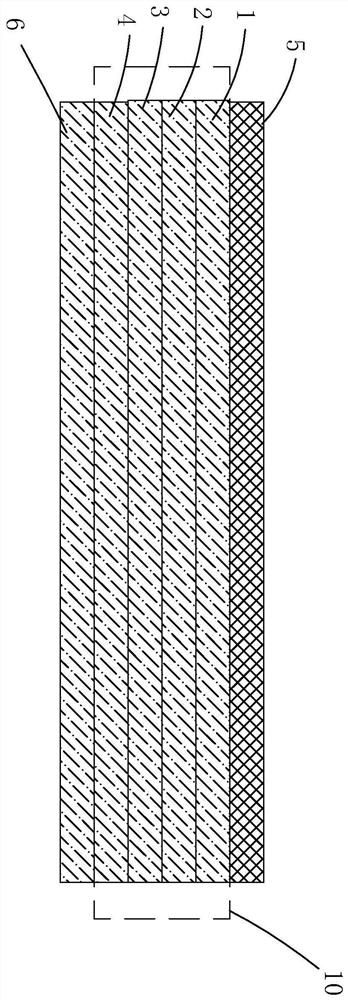

[0043] Example, combined with Figure 1 to Figure 4 As shown, a light-transmitting color film includes a color film substrate PET layer 1, an eco-solvent layer 2, a color printing ink layer 3 for displaying patterns, a printed white layer 4, a high-temperature protective film layer 5 and an adhesive layer 6.

[0044] The high temperature protective film layer 5 is arranged on the front side of the PET layer 1 of the color filter base material, the weak solvent layer 2 is attached to the back side of the PET layer 1 of the color filter base material, and the color printing ink layer 3 is located on the PET layer of the color filter base material. 1, the weak solvent layer 2 is arranged between the color filter substrate PET layer 1 and the color printing ink layer 3, and the color printing ink layer 3 is fixed on the back of the color filter substrate PET layer 1 through the weak solvent layer 2.

[0045] The printed white layer 4 is arranged on the color printing ink layer 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com