Milling chatter stability prediction method

A technology of stability prediction and milling chatter, which is applied in complex mathematical operations, instruments, design optimization/simulation, etc., can solve the problems of poor versatility and effectiveness of time-domain stability criteria, and low numerical solution efficiency, etc., to improve The effects of stability prediction accuracy, enhanced universality of criteria, and reduced truncation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

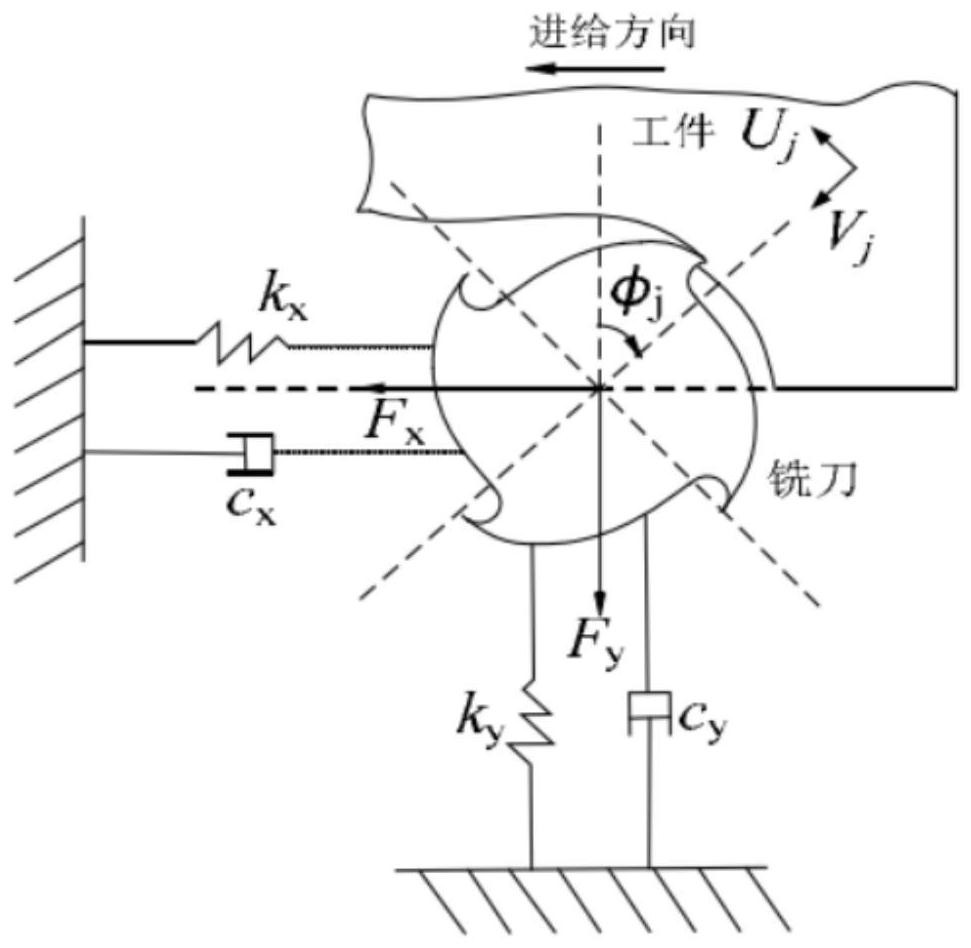

[0035] In order to realize chatter-free milling, this embodiment provides a milling chatter stability prediction method when a vertical milling machine table mills aluminum alloys, especially suitable for the stability prediction of the milling process of a cylindrical milling cutter, which specifically includes the following steps:

[0036] S1. Establish a milling process kinetic differential equation considering the regenerative effect;

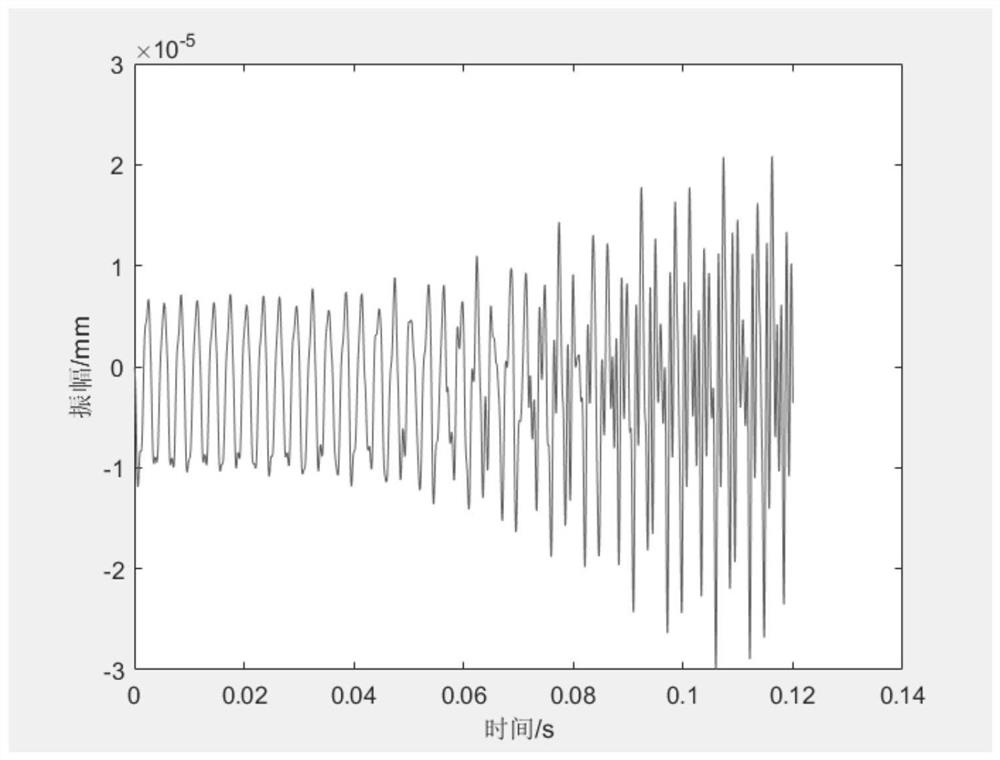

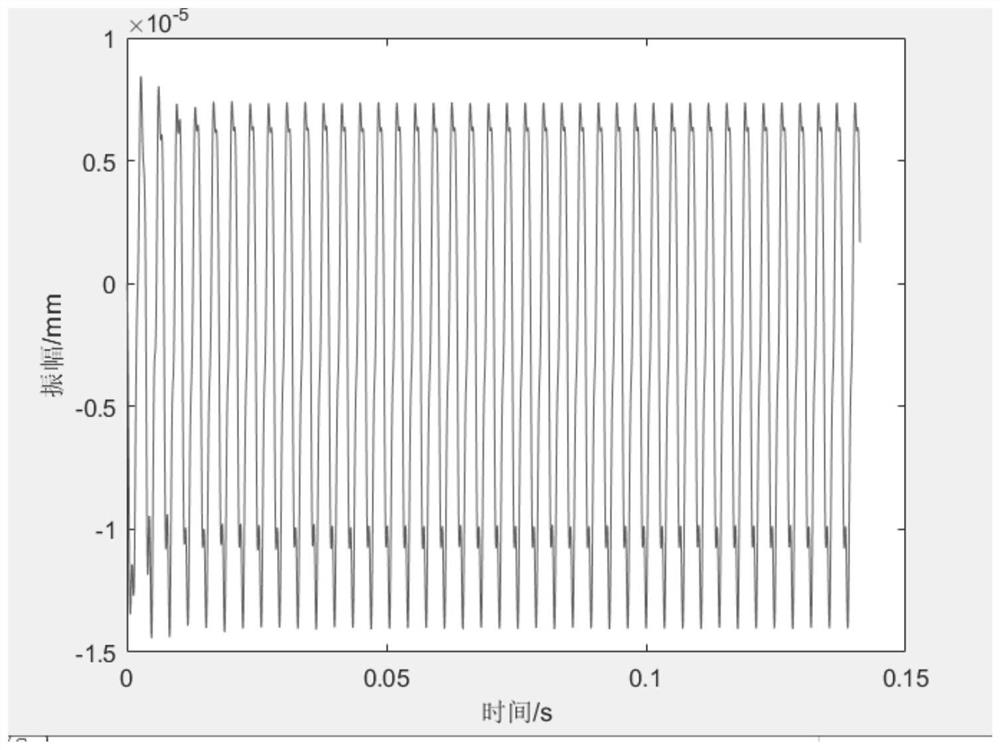

[0037] S2. Using the numerical method to solve the milling dynamics differential equation to obtain time domain signals including cutting force, tool tip and workpiece vibration;

[0038] S3. An energy-based method, using Rényi entropy to apply a stability criterion to the time-domain signal obtained from the simulation in S2, to determine whether the machining system is stable under the current cutting conditions;

[0039] S4. Changing the cutting conditions, repeating S1-S3, until the stable lobe map is obtained.

[0040] Specifically, S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com