Solar module

A technology of solar modules and front panels, applied in the field of solar modules, can solve problems such as inability to meet the double-sided power generation of photovoltaic modules, high production costs, and reduced load-bearing capacity of modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

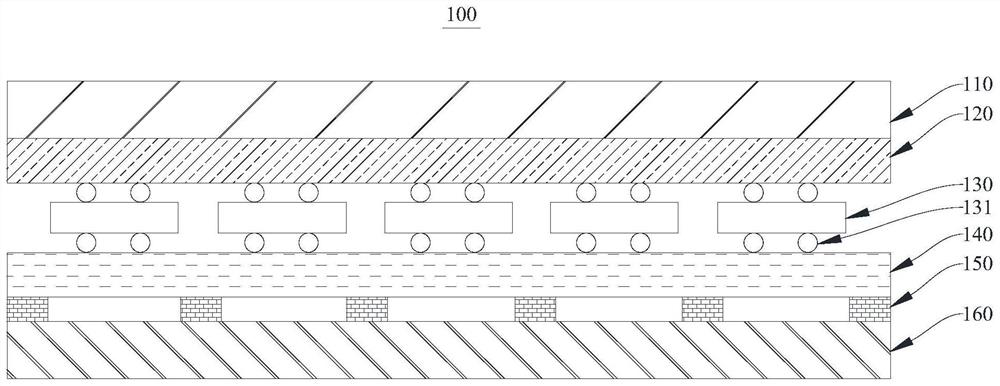

[0043] Please see figure 2 , a solar module 100 provided in this embodiment, which includes a glass front plate 110, a front encapsulant film 120, a battery sheet 130, a back encapsulant film 140, and a PC back plate 160, which are sequentially stacked from top to bottom. The plate 160 is provided with a reflective layer 150 on a non-battery sheet-covered area on the lamination surface adjacent to the battery sheet 130 .

[0044] It should be noted that the “non-covered area of the battery sheet” in the embodiment of the present application refers to the area that does not completely cover the battery sheet 130 , and usually refers to the area corresponding to the gap between the battery sheets 130 and the edge of the battery sheet 130 . Correspondingly, the reflective layer 150 has a hollowed-out area, and the hollowed-out area is located directly under the battery sheet 130; the reflective layer 150 and the PC backplane 160 are integrally formed by printing or spraying. ...

no. 2 example

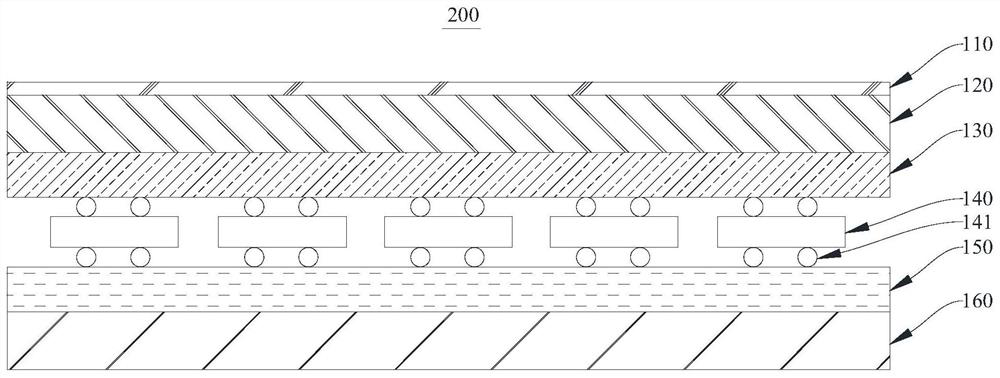

[0057] Please see image 3 , a solar module 200 provided in this embodiment, which includes a hardened layer 210, a PC front plate 220, a front encapsulant film 230, a battery sheet 240, a back encapsulant film 250 and a transparent back plate that are stacked sequentially from top to bottom 260. Using the PC front plate 220 to replace the conventional glass front plate 110 can reduce the overall weight of the component, improve the efficiency of production, transportation and installation, and also reduce the cost. Moreover, the solar module 200 of this embodiment not only meets the requirements of the double-sided power generation module, but also has better water vapor barrier properties and higher strength.

[0058] In the embodiment of the present application, the hardening layer 210 is a silicone glass resin layer, and the thickness of the hardening layer 210 is generally 0.1mm-1mm. In this embodiment, the hardened layer 210 is a 0.3 mm thick organic silicon glass resi...

no. 3 example

[0071] Please see Figure 4 , the present embodiment provides a solar module 300, the structure of which is substantially the same as that of the first embodiment, including a glass front plate 110, a front encapsulant film 120, a battery sheet 130, and a back encapsulant that are stacked sequentially from top to bottom. film 140 , reflective layer 150 and PC backplane 160 . The difference is that: the glass front plate 110 of this embodiment is coated with an anti-reflection layer 310, and the anti-reflection layer 310 can adopt a single-layer coating or a double-layer coating, that is, at least one of the upper and lower laminated surfaces of the glass front plate 110 is provided with There is an anti-reflection layer 310 . Specifically, this embodiment adopts double-layer coating, and the upper laminated surface and the lower laminated surface of the glass front plate 110 are respectively coated with an anti-reflection layer 310, that is, the solar module 300 includes an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com