Novel composite membrane based on BILP-101x as well as preparation method and application thereof

A composite membrane, a new type of technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as hindering the penetration of divalent salts, unable to effectively separate dye/salt mixed solutions, etc., to inhibit bacterial growth and improve processing capacity. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

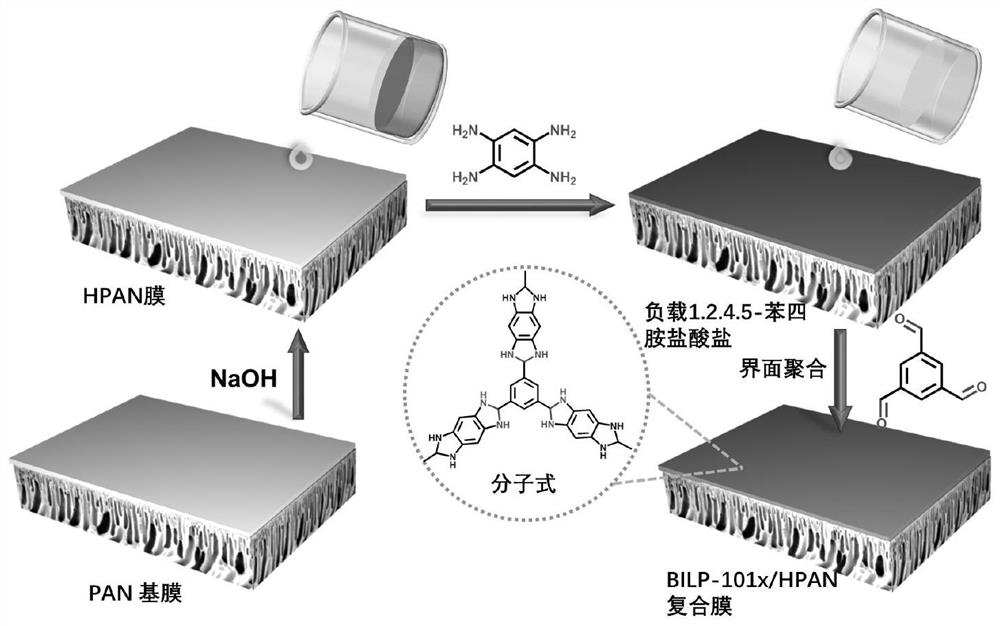

[0033] A novel composite membrane based on BILP-101x, the preparation process is as follows:

[0034] 1) Basement membrane hydrolysis: Before using the basement membrane, soak the PAN membrane in NaOH aqueous solution (2mol / L, 25°C) for 2 hours to hydrolyze the PAN membrane; then rinse the obtained hydrolyzed PAN membrane (HPAN) completely with deionized water to neutral, placed in deionized water for later use;

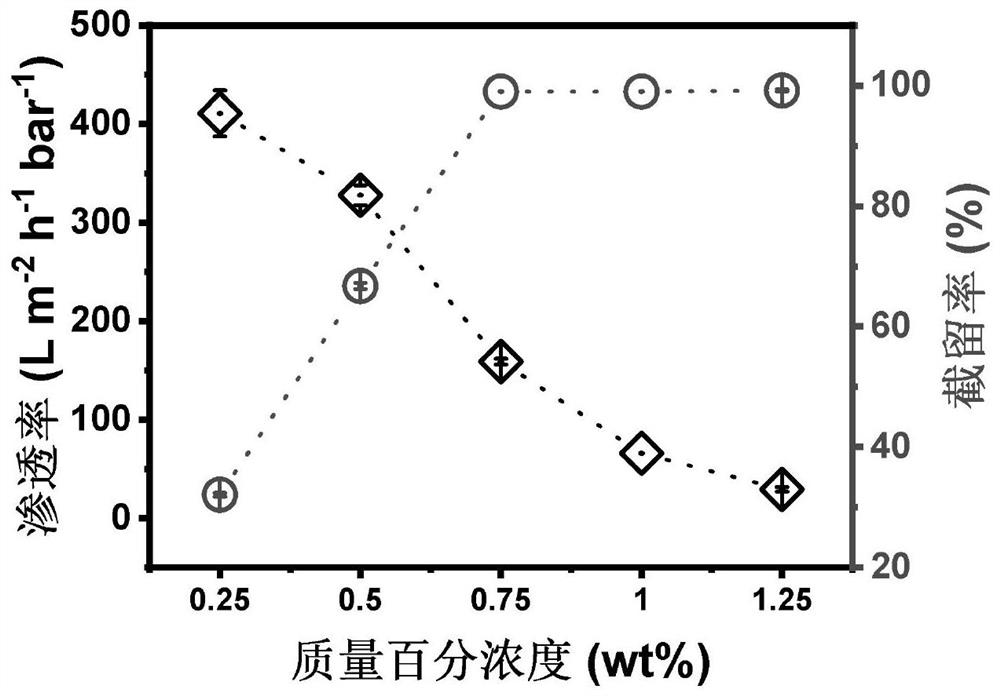

[0035] 2) Configuration of the reaction monomer solution: add 1,2,4,5-benzenetetramine tetrahydrochloride (0.0625g) into 25mL deionized water and stir for 15min at room temperature to obtain a concentration of 0.25wt%. Aqueous phase solution A; 1,3,5-triformoylbenzene (0.0275g) was dissolved in 25ml of benzene solvent at room temperature and dissolved completely by ultrasound to obtain an oil phase solution B with a mass percent concentration of 0.11wt%;

[0036] 3) The preparation process such as figure 1 As shown, the HPAN base membrane was first cut into a circl...

Embodiment 2

[0038]In step 2), change the quality of 1,2,4,5-benzenetetramine tetrahydrochloride to 0.125g, and the quality of 1,3,5-triformylbenzene to 0.055g, and the others are the same as in Example 1. An aqueous phase solution A with a mass percent concentration of 0.50 wt % and an oil phase solution B with a mass percentage concentration of 0.22 wt % were respectively obtained.

Embodiment 3

[0040] In step 2), the quality of 1,2,4,5-benzenetetramine tetrahydrochloride was changed to 0.1875g, the quality of 1,3,5-triformylbenzene was changed to 0.0825g, and the others were the same as in Example 1. An aqueous phase solution A with a mass percent concentration of 0.75 wt % and an oil phase solution B with a mass percentage concentration of 0.33 wt % were respectively obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com