A vacuum atomization dust removal and recovery device for aluminum-based alloy powder

An aluminum-based alloy and recovery device technology, which is applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of easy dust blockage, air outlet blockage, and reduced dust collection efficiency, etc., to achieve high work efficiency , simple structure and convenient operation

Active Publication Date: 2022-06-03

HENAN YUANYANG POWDER TECH CO LTD

View PDF17 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the existing 3D printer needs to use the storage room during use, and the dust collection device in the storage room still has shortcomings during use. First, the existing collection device can only collect dust floating in the air. Dust, and the dust on the surface of the material will not be collected, which reduces the scope and function of the collection device; secondly, when the existing dust collection device collects the dust, the dust is easily blocked near the air outlet, resulting in The blockage of the air outlet reduces the dust collection efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

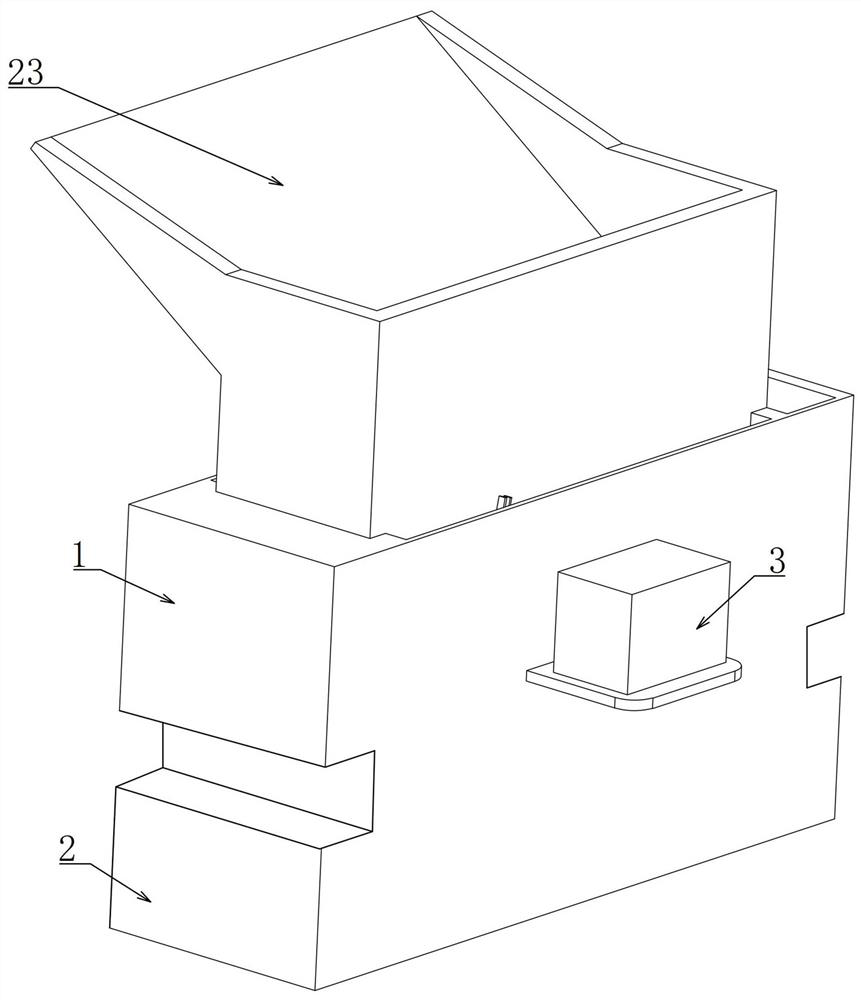

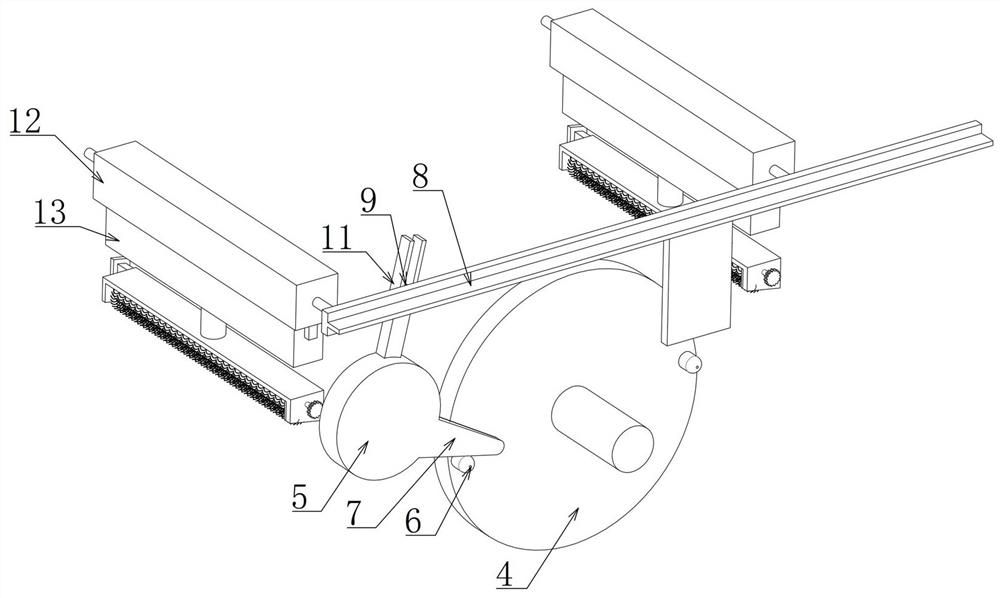

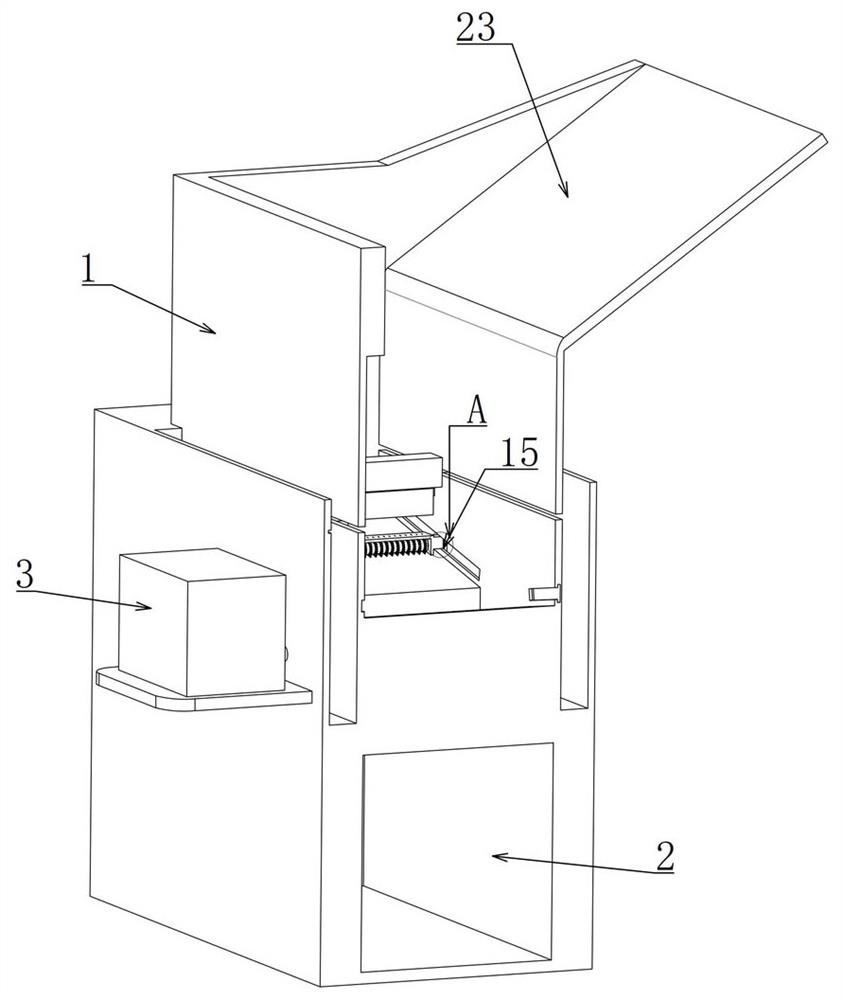

The invention provides an aluminum-based alloy powder vacuum atomization dust removal and recovery device. Aluminum alloy is the key material to realize lightweight, and the use of lightweight materials is an important means to realize lightweight equipment. Aluminum alloy, as a lightweight material, Because of its large reserves, low density, strong plasticity and corrosion resistance, excellent thermal conductivity and high strength, it is the material of choice for lightweight structures, and has broad application prospects in aerospace, transportation and other fields. Use the reciprocating motion device to drive the cleaning device to clean the inner wall, make the cylindrical roller brush closely fit on the shell blanking platform, clean the upper surface of the platform, and solve the technical problem of the blockage of the leakage port. Using the cleaning device can make The cylindrical roller brush can only rotate in one direction, which can effectively clean up the fallen powder.

Description

A kind of aluminum-based alloy powder vacuum atomization dust recovery device technical field The invention belongs to the technical field of aluminum-based alloy powder production, and is specially a kind of aluminum-based alloy powder vacuum atomization and dust removal recycling device. Background technique Aluminum alloy is the key material to realize light weight, and the use of light weight material is an important tool to realize the light weight of equipment. As a lightweight material, aluminum alloy is due to its large reserves, low density, strong plasticity and corrosion resistance, excellent thermal conductivity and electrical conductivity. It is the first choice material to achieve lightweight structure, and has a wide range of applications in aerospace, transportation and other fields. Broad application prospects, the traditional aluminum alloy processing technology mainly adopts methods such as smelting, casting and forging, and the core complex struct...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B08B9/087

CPCB08B9/087Y02P70/10

Inventor 马社俊黄松涛熊志飞陈松王洪振李相波靳争闫家涛马新华董翠玲

Owner HENAN YUANYANG POWDER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com