A process parameter optimization method for laser selective melting of high-entropy alloys

A technology of laser selective melting and process parameter optimization, applied in the field of alloy materials, it can solve the problems of inability to process optimization, inability to describe the instantaneous molten pool state, without considering the instantaneous molten pool energy density, etc., and achieve the effect of accurate optimization results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The printing powder is FeCoCrNi and other atomic concentration powder with a particle size of 15-48 microns. A 316L plate was used as the SLM substrate with a size of 250mm×250mm×15mm, and the oil and dirt on the surface were cleaned with acetone and alcohol respectively. Sandblast the surface with a sandblaster.

[0041] The AM-400 laser 3D printing equipment produced by Renishaw Company was used for printing, and a block with a size of 5mm×5mm×5mm was constructed in the software Renishaw-QuantAM that comes with the Renishaw equipment. The layer thickness is 40 microns, and the interlayer rotation angle is 67° to release residual stress. Before printing, the printing chamber is evacuated, the oxygen content is less than 500 ppm, and argon gas is used for protection. After printing, the specimen is cooled with the chamber for 2 hours.

[0042] In this experimental example, three main process parameters of power, exposure time, and line-to-point distance are used for pr...

Embodiment 1

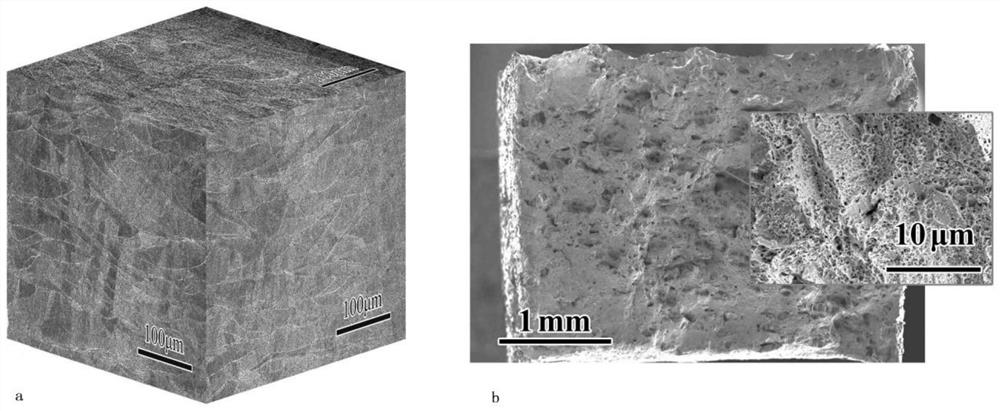

[0053] The optical microscope photo of the sample printed by laser selective melting with the optimized process parameters of Example 1 is shown in figure 1 a, Scanning electron microscope morphology of tensile fracture figure 1 b.

[0054] The energy density can be calculated by the following formula: VED=PT / H 2 L

[0055] VED is energy density J / mm 3 , L is the layer thickness of 40 μm, and the following comparative examples select the parameter combination with the same energy density as the optimized process combination.

Embodiment 2

[0081] The printing powder is FeCoCrNiMn and other atomic concentration powder with a particle size of 15-48 microns. A 316L plate was used as the SLM substrate with a size of 250mm×250mm×15mm, and the oil and dirt on the surface were cleaned with acetone and alcohol respectively. Sandblast the surface with a sandblaster.

[0082] The AM-400 laser 3D printing equipment produced by Renishaw Company was used for printing, and a block with a size of 5mm×5mm×5mm was constructed in the software Renishaw-QuantAM that comes with the Renishaw equipment. The layer thickness is 40 microns, and the interlayer rotation angle is 67° to release residual stress. Before printing, the printing chamber is evacuated, the oxygen content is less than 500 ppm, and argon gas is used for protection. After printing, the specimen is cooled with the chamber for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com